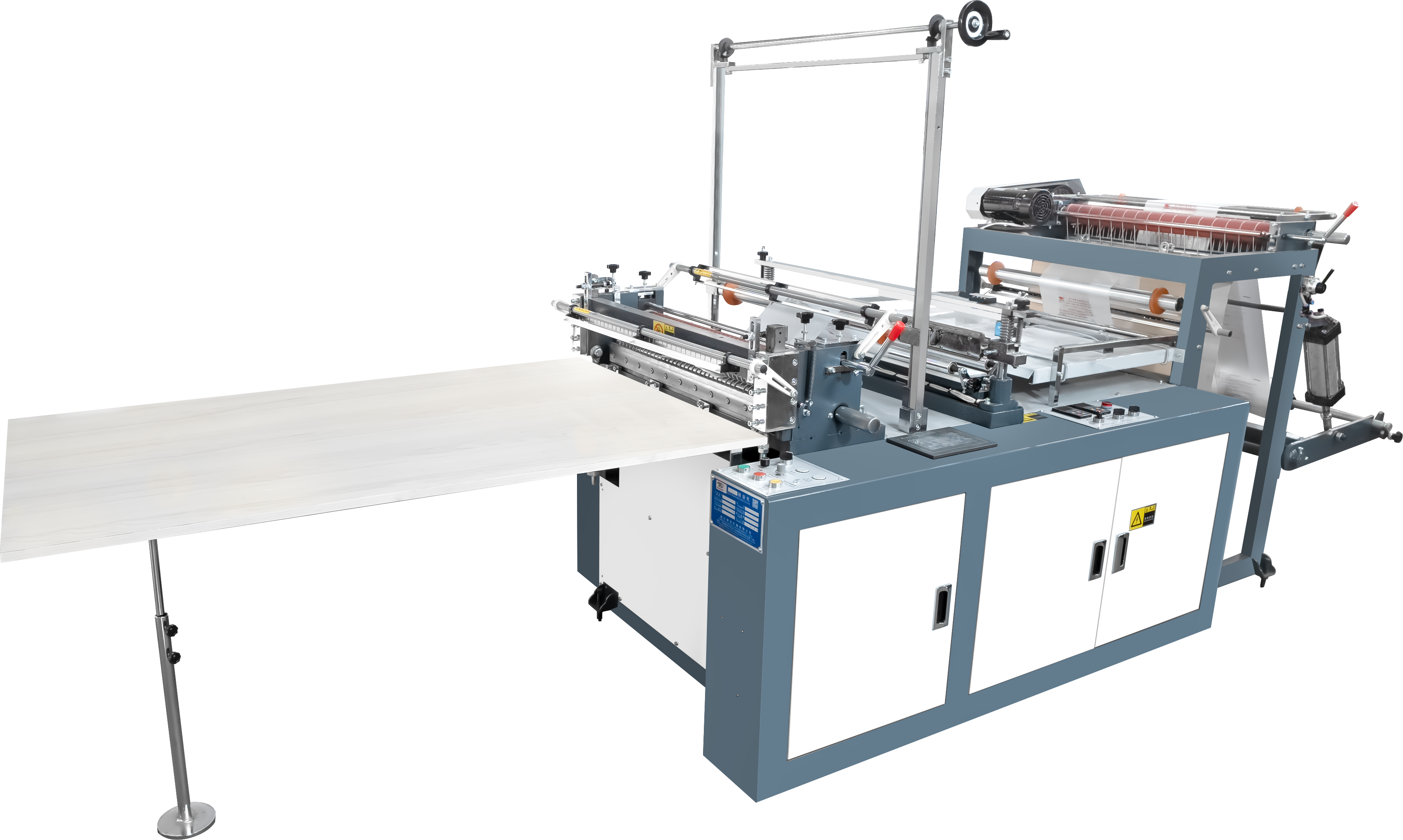

What Defines a Frosted Plastic Bag Making Machine?

Frosted plastic bag machines work by altering the surface of films so they scatter light evenly while giving that distinctive matte feel we all recognize. What sets these apart from regular polyethylene bag makers is their special setup with embossing rollers that have tiny patterns on them, creating those frosty looking bumps as the material gets pushed through during production. Some high end versions even employ a two step cooling process first using fast moving air then plunging into cool water around room temperature to set the texture properly before any finishing touches get applied. Most companies tend to go for low density polyethylene when making these bags because it just looks better when frosted than high density alternatives, which is why LDPE remains the material of choice across the industry.

Core Components of the Machine for Frosted Film Production

Three subsystems enable frosted film manufacturing:

- Asymmetric screw extruders melt resins at controlled 160–190°C gradients to prevent overheating

- Matte-finish chill rolls (Ra 3.2–6.3 µm surface roughness) solidify films while imprinting micro-textures

- Atmospheric plasma units oxidize surfaces to enhance ink adhesion on treated areas

Modern machines maintain √0.02 mm thickness variation across 2m film widths using laser-guided roller alignment, ensuring uniform frosting and structural integrity.

Integration of Frosted Finish Techniques in Bag Machinery Workflow

Frosting starts right after the extrusion stage when the film goes through texture rollers heated between around 65 to 80 degrees Celsius to get those patterns just right. After this texturing step, corona discharge equipment operating somewhere between 18 and 40 kilohertz boosts surface energy levels up to approximately 42-56 dynes per centimeter. This makes sure seals hold properly while keeping the frost patterns intact throughout production runs. Manufacturers keep an eye on how opaque the material becomes during processing, aiming for about 85-92% haze visibility. They also check tensile strength measurements which need to stay above 18 megapascals both machine direction and transverse direction. By constantly adjusting roller pressures within plus or minus 5%, operators maintain product consistency across batches despite minor fluctuations in raw materials or environmental conditions.

The Frosted Bag Manufacturing Process: From Extrusion to Surface Treatment

Step-by-Step Plastic Bag Manufacturing with Frosted Aesthetic

Making those frosted effect bags involves several key steps in the production line. Step one starts with melting down resin pellets inside an extruder machine heated between around 160 to 200 degrees Celsius until they become this thick, gooey polymer substance. Next comes the shaping process as this molten material goes through what's called a circular die, creating a tube like film. At this stage, special cooling fans start working their magic to create that signature matte finish we all recognize. Throughout this whole process, tension controlled rollers keep everything looking consistent and opaque. Then there are these cutter sealers that actually create those neat little side seams along the bag. And last but not least, before sending them off for printing, manufacturers apply something called corona treatment which makes sure any printed designs stick properly onto those frosty surfaces.

Role of Extrusion in Creating Frosted Texture on Polyethylene Film

The extrusion unit is central to achieving consistent frosted finishes. Key factors include:

- Barrel temperature zones: 5–10°C variations across heating segments influence polymer crystallization

- Die gap adjustments: 0.8–1.2mm openings optimize film thickness for light diffusion

- Air ring cooling: Asymmetric airflow generates microsurface irregularities (Ra 2.5–3.8µm) that scatter light

These parameters allow the machine to produce uniform frosted textures on LDPE, HDPE, and blended films without chemical additives.

Surface Treatment Methods: Cold Rollers and Corona Treatment for Opacity

Two primary methods enhance frosted effects:

| Method | Mechanism | Opacity Range | Energy Consumption |

|---|---|---|---|

| Cold Rollers | Chilled (12–15°C) steel drums compress film surface | 65–78% | 8–12 kW/hr |

| Corona | 10–40 kHz electrical discharge oxidizes surface layer | 72–85% | 15–22 kW/hr |

Cold rollers deliver tactile matte finishes ideal for premium retail packaging, while corona treatment ensures durable opacity in industrial films. Combining both methods is common for multilayer frosted zipper bags requiring both aesthetics and strength.

Material Selection for Frosted Bags: LDPE, HDPE, and LLDPE Compared

Performance Differences of LDPE, HDPE, and LLDPE in Frosted Applications

The type of resin used makes all the difference when it comes to achieving good frosted effects. LDPE is known for being really flexible and giving those nice even matte finishes because of how its molecules branch out, scattering light around pretty well. That's why it works so great for things like retail packaging where appearance matters. HDPE on the other hand gives much more rigidity and starts off more opaque, but manufacturers often need to throw in some additives to get consistent frosting results since the straight chain molecules don't let light scatter as freely. Then there's LLDPE which sits somewhere in between strength and texture quality. With those shorter chain branches, it actually manages to create about 15 to 20 percent better surface texture compared to HDPE without sacrificing tear resistance too much. Most people find this balance really useful for applications where both looks and durability count.

| Blend Combination | Frosting Opacity (%) | Tear Strength (g/µm) |

|---|---|---|

| LDPE + 10% HDPE | 82 | 220 |

| LLDPE + 5% MDPE | 78 | 290 |

| HDPE + 15% LDPE | 75 | 180 |

How Resin Quality Impacts Clarity, Strength, and Frosting Consistency

Resins that have high purity levels and MFR values between 0.3 and 2.0 grams per 10 minutes work best for stable extrusion processes and create consistent frosting effects across surfaces. When working with lower quality LDPE materials where polymer chains aren't uniform, we often see those annoying patches of opacity because light gets scattered differently through the material. For HDPE products made from virgin material with densities above 0.945 grams per cubic centimeter, there's significantly less stress whitening during processing, plus these materials hold onto around 90% of their original tensile strength even after going through the frosting treatment. The problem comes when recycled content goes beyond 8% in LLDPE formulations. At that point, puncture resistance drops somewhere around 34%, which makes these materials unsuitable for many demanding industrial applications where durability matters most.

Blending Resins for Optimal Opacity and Tactile Texture in Frosted Films

Modern co-extrusion setups combine LDPE as the base material with various LLDPE-HDPE surface blends, which boosts the tactile feel by around 40 percent while reducing those costly additives by nearly 20%. When manufacturers mix roughly 70% LDPE with 30% LLDPE, they get that important cross direction tear strength of about 18 Newtons per square millimeter something absolutely necessary for those frosted zipper bag applications. And when opacity becomes a real concern? Just throw in somewhere between 12 and 15% TiO2 masterbatch into the HDPE formulation. This tweak makes light scatter much better across surfaces, improving visibility by almost half without slowing down the whole extrusion process at all.

Specialized Adaptations for Frosted Zipper Bag Production

Modifying the Plastic Bag Making Machine for Frosted Zipper Bags

Producing frosted zipper bags requires precise adjustments to maintain surface opacity while integrating zipper tracks. Operators fine-tune extrusion temperature (±5°C) and roller compression to avoid texture distortion. Modified die heads ensure continuous flow for both frosted film and transparent zipper strips, preventing interfacial weaknesses that could lead to delamination.

Compatible Materials (LDPE, MDPE, PEVA, EVA) for Frosted Zipper Films

Frosted zipper bags use engineered resins tailored for light scattering and sealing performance:

| Material | Frosting Effectiveness | Sealing Performance | Common Use Cases |

|---|---|---|---|

| LDPE | High opacity | Low-temperature | Retail packaging |

| MDPE | Moderate opacity | High-strength | Industrial bags |

| PEVA | Consistent matte finish | Flexible seals | Food-safe pouches |

| EVA | Slight translucency | Extreme elasticity | Freezer storage |

EVA and PEVA blends (up to 18% vinyl acetate content) improve tactile texture without sacrificing zipper functionality, according to 2023 polymer engineering studies.

Precision Sealing and Lamination Units for Zipper Integration

Dual-stage sealing ensures reliable zipper attachment: infrared pre-heating (120–140°C) bonds the strip to frosted film, followed by ultrasonic lamination for airtight edges. Laser sensors monitor alignment within 0.3 mm tolerance, automatically adjusting tension to prevent puckering or delamination during high-speed production (40–60 bags/minute).

Customization Options: Printing, Perforations, and Design Flexibility

Manufacturers leverage modern bag-making systems to combine frosted aesthetics with functional enhancements aligned with market demands.

Adding Perforations and Tear-Notches in the Frosted Bag Making Process

Integrated laser perforation systems create precise tear lines at speeds up to 120 bags/minute. Adjustable hole density (10–50 holes/inch) balances easy opening with structural integrity, making them ideal for snack or produce packaging.

Digital and Flexographic Printing on Frosted Plastic Films

UV-cured inkjet modules achieve 98% opacity for sharp branding on frosted LDPE and HDPE films. Flexographic printing paired with cold-foil stamping adds metallic accents without disrupting the matte surface, enhancing shelf appeal.

Meeting Consumer Demand Through Aesthetic and Functional Customization

Brands increasingly request dual-texture bags with frosted and transparent zones, achieved through selective corona treatment during extrusion. To meet sustainability goals, inline systems print recycled-content indicators directly during production, providing transparency without slowing output.

FAQ Section

What is a frosted plastic bag?

A frosted plastic bag is a type of bag made from polyethylene with a matte finish. It's created by processing the surface to scatter light, resulting in a frosty appearance.

What material is preferred for frosted plastic bags?

Low-density polyethylene (LDPE) is preferred for making frosted plastic bags due to its flexibility and the even matte finish it provides.

How is the frosted effect achieved in plastic bags?

The effect is achieved through embossing rollers and specific cooling processes during production, resulting in a textured surface that scatters light.

Can frosted plastic bags be customized?

Yes, frosted plastic bags can be customized with printing, perforations, and design flexibility to meet consumer demand.

Table of Contents

- What Defines a Frosted Plastic Bag Making Machine?

- Core Components of the Machine for Frosted Film Production

- Integration of Frosted Finish Techniques in Bag Machinery Workflow

- The Frosted Bag Manufacturing Process: From Extrusion to Surface Treatment

- Material Selection for Frosted Bags: LDPE, HDPE, and LLDPE Compared

- Specialized Adaptations for Frosted Zipper Bag Production

- Customization Options: Printing, Perforations, and Design Flexibility

- FAQ Section