Understanding Blown Film Extrusion for High-Density Plastics

The blown film extrusion process: How HDPE, PP, and other high-density plastics are processed

In blown film extrusion, polymer resins get turned into those thin plastic films we see everywhere. The actual process starts when plastic pellets are fed into an extruder barrel using gravimetric controls, especially important for materials like high density polyethylene (HDPE) and polypropylene (PP). Once melted, the polymer gets pushed through what's called an annular die, creating this long tube-like bubble that operators then inflate upwards with carefully controlled air pressure. This inflation step is pretty critical because it gives the film its strength in both directions, something manufacturers call biaxial orientation. For HDPE specifically, temperature management becomes really tricky since these high density materials need to stay within a narrow range around 180 to 230 degrees Celsius. Get too hot and the crystalline structure breaks down, but too cold means the bubble won't stabilize properly during production.

Key differences between HDPE, LDPE, PP, and PVC in film blowing applications

| Material | Melt Temp (°C) | Density (g/cm³) | Tensile Strength (MPa) |

|---|---|---|---|

| HDPE | 130–180 | 0.941–0.965 | 20–32 |

| LDPE | 105–115 | 0.910–0.925 | 10–20 |

| PP | 160–170 | 0.895–0.920 | 25–38 |

| PVC | 160–210 | 1.3–1.45 | 40–60 |

HDPE's high crystallinity provides excellent moisture barrier properties, making it ideal for packaging films. PP offers superior clarity and stiffness, preferred in consumer product wraps. PVC demands careful thermal management due to degradation risks above 200°C, requiring specialized processing equipment.

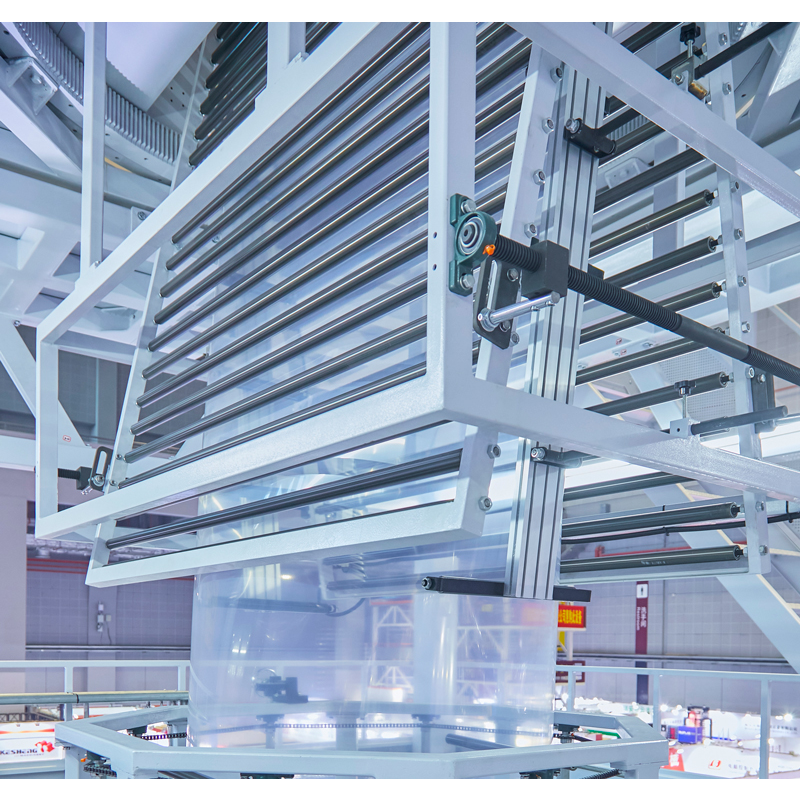

How machine design affects material integrity and production efficiency

Film blowing machine design directly influences polymer behavior through three key elements:

- Screw L/D Ratios: A 30:1 or higher ratio ensures complete melting of HDPE without overheating.

- Air Ring Geometry: Dual-lip air rings enhance bubble stability, reducing thickness variation to ±2%.

- Cooling Capacity: PP requires 25% faster quenching than HDPE to avoid crystallization defects.

Advanced systems integrate IR thickness sensors and automatic die lip adjustment, maintaining material waste below 5% even at high production speeds.

Core Technologies Driving High-Performance Film Blowing Machines

Spiral Die Technology and Its Role in Ensuring Film Homogeneity for HDPE

The spiral die design gets rid of those pesky weld lines while making sure the molten plastic spreads evenly throughout materials such as HDPE and polypropylene. These special dies work by channeling the polymer along twisting paths, keeping pressure stable across the entire surface. Most importantly, they cut down on thickness differences to around 3% or less, which matters a lot when manufacturing sensitive products like medical packaging or food barriers. For companies working with multiple layers in their extrusion processes, getting this kind of uniformity means each layer stays intact and functions properly, something that can't be compromised in quality-sensitive applications.

Precision Temperature and Pressure Control in Modern Extrusion Systems

The best extrusion systems rely on closed loop control mechanisms to keep those critical barrel temperatures right around 1.5 degrees Celsius either side of target, plus they manage internal bubble pressure variations down to about 0.2 bar. When working with HDPE materials specifically, getting these parameters just right makes all the difference for maintaining proper crystal structures throughout the whole process window which typically falls between 200 and 250 degrees Celsius. Production facilities often install adjustable cooling rings along the line as well. These help stabilize the bubble formation significantly, allowing operators to push output rates beyond 250 meters per minute while still hitting those thin film requirements ranging from 10 up to 150 microns thick across different applications.

Gravimetric Blending for Consistent Polymer Formulation and Quality

Loss-in-weight gravimetric feeders achieve 99.8% dosing accuracy, crucial for filled HDPE compounds and PP-based coextrusions. This eliminates the ±5% errors common in volumetric systems, reducing material waste by 12–18% (Plastics Technology Report 2023). Real-time viscosity monitoring adjusts blending ratios when processing recycled HDPE, maintaining tensile strength within 1.5% of virgin material benchmarks.

Ensuring Film Quality and Thickness Uniformity in High-Speed Production

Real-Time Gauge Control Systems for Consistent Film Thickness

Today's film blowing machines can keep thickness variations within about 2-3% thanks to infrared sensors working alongside automatic air ring adjustments. The scanning systems check around 150 to 200 spots every minute, sending all that info to control units which then tweak the die gaps and cooling speeds as needed. This kind of instant feedback basically gets rid of those pesky manual calibration mistakes and cuts down on wasted materials by roughly 12 to 15 percent. When dealing with HDPE plastics that have anywhere from 40 to 60% more melt strength compared to regular LDPE, these advanced systems really shine because they help prevent problems caused by inconsistent stretching during production runs when the material's viscosity starts fluctuating.

Challenges in Maintaining Uniformity With HDPE and PP During Extrusion

The high crystallinity of HDPE, which ranges between 65% and 85%, means it needs about 30 to 40 percent faster cooling compared to polypropylene if we want to avoid issues with inconsistent thickness. When running at speeds above 400 meters per minute, polypropylene films tend to develop problems like neck-in instability and thicker edges because they crystallize so quickly. To tackle these challenges, manufacturers often turn to dual-lip air rings capable of maintaining temperatures within plus or minus one degree Celsius, along with gravimetric screw feeders that keep polymer density variations below half a percent. Industry statistics show that when companies combine these technologies with predictive maintenance systems, they can cut down on production downtime by around 18%. These improvements make a real difference in plant efficiency.

Automation and Integrated Control Systems for Maximum Efficiency

How Automation Reduces Waste and Increases Throughput in Film Blowing

According to the 2023 Polymer Processing Report, closed loop automation can cut down on material waste by around 34%. When it comes to actual implementation, real time thickness monitoring makes those tiny adjustments to die lips within about plus or minus 2 microns. This helps stop defects from happening while still keeping production going strong over 400 kilograms per hour when working with HDPE materials. What's really impressive is how these systems tie together different components like melt pumps, air rings, and haul off units all at once. They manage to keep that bubble stable even when dealing with blow up ratios as high as 9 to 1, which matters a lot during those fast paced manufacturing runs where every second counts.

Turnkey Solutions: Integrating Film Blowing Machines with Centralized Control Systems

Leading manufacturers deploy unified HMI platforms that integrate:

- Polymer drying and feeding automation (dew point < -40°C)

- Spiral mandrel temperature zoning with PID accuracy (±0.5°C)

- Web handling tension control (±1% deviation across 6m layflat)

This integration cuts setup times by 60% and enables fast material changeovers, improving operational agility.

Case Study: Performance Improvements in an HDPE Film Line with Automated Controls

One European packaging company saw their uptime jump to 91% last year, an impressive 18% improvement from the previous year, after installing smart predictive maintenance on their film blowing machine. Their production line now makes those 12-layer barrier films at a speed of 27 meters per minute, keeping thickness variations below 3.5%. The system's AI brain crunches through over 1,200 different parameters every single second. And get this - when they started using automated thermal profiles, energy costs dropped by 22% per kilogram produced. These kinds of upgrades really show what happens when manufacturers bring together smart controls and traditional processes. Quality gets better, waste goes down, and the bottom line looks healthier too.

Customization and Industrial Versatility of Film Blowing Equipment

Tailoring Film Blowing Machines to Specific Polymers and Output Needs

Film blowing machines designed with modular components can handle all sorts of different polymers. For instance, HDPE typically needs processing temperatures around 170 to 200 degrees Celsius, whereas polypropylene demands much stricter temperature management, usually within plus or minus 2 degrees. The adjustable die gap range from 0.8 millimeters up to 2.5 mm makes it possible to switch back and forth between simple single layer films and those complex three layer coextrusions. According to recent industry data, more than two thirds of manufacturers these days are asking for equipment that can work with multiple materials. This includes handling eco friendly PLA bioplastics alongside recycled HDPE mixtures, all without having to stop production for changes. The trend shows no sign of slowing down as sustainability becomes increasingly important across manufacturing sectors.

| Feature | Blown Film Extrusion | MDO Processing |

|---|---|---|

| Material Versatility | High (HDPE, PP, EVOH) | Limited to PP, PA |

| Orientation | Balanced MD/TD | Machine Direction Only |

| Production Speed | Up to 250 m/min | 300–400 m/min |

Comparing Blown Film Extrusion With MDO and Other Processing Techniques

The blown film extrusion process stands out when it comes to creating those intricate 9-layer barrier films used in food packaging applications. These films maintain good balance between machine direction and transverse direction properties which is pretty important for quality control. Meanwhile, MDO systems definitely boost the tensile strength of PP tapes, though they can only achieve uniaxial orientation at best. When looking at gravimetric thickness variation, blown film stays within about 2%, which beats cast extrusion's performance of around 5%. That's why many manufacturers prefer blown film for medical grade products where consistency matters most. Another advantage worth mentioning is the integrated air ring cooling system that cuts down on crystallinity variations by roughly 40% compared to traditional calendering techniques. This makes a real difference in product reliability across different batches.

Frequently Asked Questions (FAQ)

What is blown film extrusion?

Blown film extrusion is a process where polymer resins, such as HDPE and PP, are melted and shaped into thin films using an extruder and a die. The films are then inflated with air to achieve a specific thickness and strength.

Why is temperature control important in blown film extrusion?

Temperature control is crucial because it helps maintain the polymer's crystalline structure and ensures stability during production. Incorrect temperatures can lead to defects or unstable bubbles in the film.

How does machine design impact film quality in blown film extrusion?

Machine design affects film quality through elements like screw L/D ratios, air ring geometry, and cooling capacity, which are essential for precise melting, bubble stability, and quenching rates.

What are the benefits of automation in film blowing?

Automation improves efficiency by reducing waste, increasing throughput, and stabilizing the production bubble. It ensures consistent film thickness and quality through real-time monitoring and adjustments.

Can blow film extrusion machines handle different polymer types?

Yes, blow film extrusion machines can handle various polymers, provided they are designed with components that allow for modular adjustments in temperature, die gaps, and layer complexions.

Table of Contents

- Understanding Blown Film Extrusion for High-Density Plastics

- Core Technologies Driving High-Performance Film Blowing Machines

- Ensuring Film Quality and Thickness Uniformity in High-Speed Production

- Automation and Integrated Control Systems for Maximum Efficiency

- Customization and Industrial Versatility of Film Blowing Equipment

- Frequently Asked Questions (FAQ)