How Plastic Bag Making Machines Enable High-Quality Vacuum Sealing

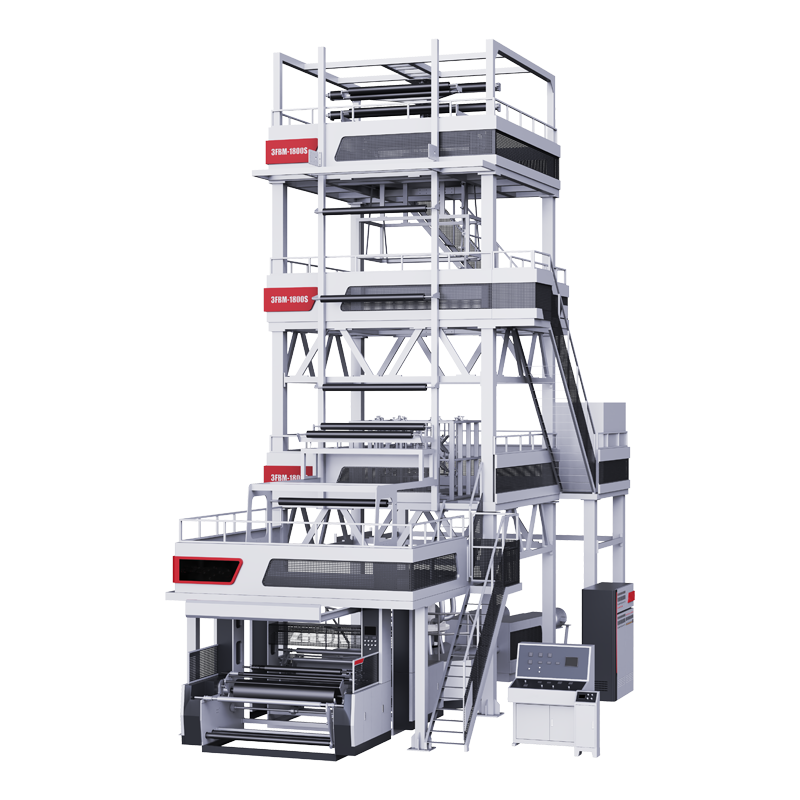

The Role of Plastic Bag Making Machine Technology in Producing Vacuum-Ready Films

Today's plastic bag manufacturing equipment relies on sophisticated co-extrusion technology to create those multi-layer films needed for proper vacuum sealing applications. The basic setup usually includes a polyethylene inner layer that creates those tight seals we need, paired with either nylon or EVOH as the outer protective layer against oxygen getting through. Getting the thickness just right matters a lot here too. Most machines can control film thickness within about 0.001 inches, which keeps the material dense enough so the vacuum holds properly. They also throw in some anti-fog stuff to stop moisture from forming inside food packages. Research indicates that these layered films cut down on oxygen passing through by around 93 percent when compared to regular single layer options, meaning products stay fresh much longer on store shelves.

Integration Between Bag Formation and Vacuum Sealing in Automated Packaging Lines

Leading producers connect their plastic bag making equipment straight to the vacuum chambers below using those PLC systems we all know about, getting cycle times down to around 2.3 seconds per package in most cases. When these machines work together so smoothly, there's no need for workers to touch the product manually which cuts down on contamination problems and those pesky seal issues that waste so much material. The servo driven tension controls keep everything lined up pretty well too, staying within about half a millimeter even when running at speeds that can crank out nearly 200 bags every single minute. And let's not forget the built in quality checkers that spot bad seals bigger than 50 microns and kick them right out of the line before they ever make it to packaging. This means fewer rejects overall and better customer satisfaction in the long run.

Ensuring Material Integrity for Air-Tight, Durable Vacuum-Sealed Plastic Packages

To perform reliably under vacuum conditions, plastic bags must meet strict performance standards:

| Test Parameter | Standard Requirement | Industry Benchmark |

|---|---|---|

| Burst Strength | ≤35 psi | 42 psi (ASTM D2582-21) |

| Seal Peel Resistance | ≤4.5 N/15mm | 5.8 N/15mm (ISO 527-3) |

| Oxygen Transmission Rate | ≤15 cc/m²/day | <8 cc/m²/day (FDA 21 CFR) |

Advanced production lines employ inline thickness gauges and thermal imaging to monitor these parameters in real time. The system adjusts extrusion temperatures and sealing pressures within 0.1-second intervals, maintaining consistency. As demonstrated in recent research, this closed-loop control achieves 99.6% defect-free output for vacuum-ready packaging films.

Core Features of a Vacuum-Optimized Plastic Bag Making Machine

Material Compatibility: Creating Strong, Flexible Plastic Bags for Vacuum Sealing

Plastic bag manufacturing machines designed for vacuum processes work with various materials including polyethylene (PE), polypropylene (PP), and those fancy multilayer stuff like PE/EVOH/PE combinations. What makes these materials special is their ability to stay flexible yet tough against punctures, plus they create good barriers against oxygen getting through. Most films end up between about 80 to 150 microns thick, which seems to strike just the right balance between being strong enough but still capable of forming solid seals. The extrusion settings need careful adjustment so the layers don't separate when subjected to those intense pressure conditions during sealing operations. When it comes to packaging food products specifically, these barrier layers do double duty by keeping things fresh inside while also wrapping snugly around whatever shape the product happens to be.

Precision Heat Sealing and Cutting Systems to Prevent Air Leakage

Temperature control modules maintain heat seal bars within ±1°C of setpoints, crucial for forming reliable, air-tight seals. Laser-guided cutting systems achieve ±0.3mm accuracy, preventing microtears that compromise vacuum integrity. Dual-side cooling solidifies seals 25% faster than conventional methods, minimizing wrinkles and improving structural strength.

Automation and Integration with Packaging Machinery for Consistent Output

The servo driven bag making machines work together with fillers and sealers through those PLC systems, which cuts down on misalignment problems by about ninety percent when compared to what happens during manual operation. For thickness control, ultrasonic sensors are constantly checking things out in real time, so they can tweak the extrusion speed as needed to maintain film consistency within just five percent variation. When it comes to high speed versions, these actually connect pretty well with robotic palletizing equipment too. We're talking about production speeds that hit between 120 and 150 bags every single minute in setups where everything runs completely automatic from start to finish.

Energy-Efficient Design for High-Volume, Continuous Production Runs

Variable-frequency drives (VFDs) lower energy consumption by 30–40% during low-demand periods compared to fixed-speed motors. Heat recovery systems capture 65% of waste thermal energy from sealing processes and reuse it to pre-heat resins. Modular designs enable selective power activation of components, reducing idle energy usage by 50% in batch production settings.

From Resin to Ready-to-Use: The Production Process of Vacuum Packaging Bags

Film Extrusion and Cooling: Forming Uniform Base Material in the Plastic Bag Making Machine

The whole thing begins when those little polymer resin pellets get dumped into the plastic bag making machine. Inside, they melt down and then get pushed through what looks like a big ring (that's the circular die) to form this long tube shape. Next comes the cooling part which is pretty important too. Manufacturers either run the hot plastic over cold rollers or blast it with air jets until it hardens into something with consistent thickness around 50 to 150 microns thick. Getting this right matters a lot for how well the bags hold up under vacuum conditions later on. If the cooling isn't even throughout, we end up with weak areas in the plastic because of inconsistent crystal formation inside the material. Proper cooling makes sure everything passes the ASTM D882-18 standards for strength testing without any issues.

Bag Conversion: Cutting, Shaping, and Sealing for Vacuum Packaging Standards

The automated cutting process trims the cooled film down to exact measurements before moving on to the heat sealing stage which operates around 130 to 160 degrees Celsius to create those crucial airtight side seams. With laser guided alignment keeping things within half a millimeter tolerance, there's practically no chance of those tiny gaps forming that might compromise the vacuum seal. When it comes time to join the layers together, high frequency welding takes over instead of traditional adhesives. This method produces really strong seals that can withstand pulling forces ranging from about 3.5 to 5.5 Newtons per centimeter. These results meet all the requirements set out in the ISO 527-3 standard, so manufacturers know they're getting quality that meets industry expectations.

Quality Assurance: Testing for Thickness, Seal Strength, and Air-Tightness

Final quality checks include:

- Thickness uniformity: Ultrasonic sensors measure 20–30 points per roll, ensuring tolerances stay within ±5%

- Seal integrity: Pressure decay tests using 0.8–1 bar air injections identify leaks ≤10 µm

- Material durability: Cyclic fatigue testing simulates 6–12 months of storage stress

These protocols ensure oxygen transmission rates remain below 0.01% throughout the bag’s lifecycle, extending product shelf life by 3–5 times compared to non-vacuum packaging.

Applications and Industry Demand for Vacuum-Sealed Plastic Packaging

Vacuum-sealed plastic packaging is now vital across multiple sectors, combining preservation, protection, and efficiency. Advanced plastic bag making machines support large-scale production of customized, air-tight solutions—from perishable foods to sterile medical devices. Below are three key areas driving market expansion.

Extending Shelf Life in Food Packaging With Vacuum-Sealed Plastic Bags

When we take out the oxygen, vacuum sealing really slows down those pesky microbes and can actually keep food fresh 3 to 5 times longer than usual. And this matters a lot when it comes to reducing waste because about six out of ten people throw away food at home according to recent studies. The market for vacuum-packed foods looks set to balloon from around $7.9 billion right now to over $11 billion within six years as more folks order takeout style meals and shop groceries online. These days, manufacturers are using advanced machinery to create high barrier films that stop air from getting through, which helps maintain the taste and texture of meats, cheeses, and even fruits and vegetables after they've been packaged.

Medical and Pharmaceutical Uses for Sterile, Hermetically Sealed Packages

Healthcare relies heavily on vacuum sealed plastic packaging to keep surgical tools, implants, and various medications free from contaminants. The airtight nature of these packages ensures that everything stays sterile while being stored or moved around, something that meets those important ISO 11607 guidelines for proper medical packaging. Many pharmaceutical companies actually count on these precisely sealed pouches when dealing with drugs that are sensitive to moisture. Tests show that most batches have incredibly low leak rates, sometimes under 0.01%. Such dependable packaging cuts down on product recalls and ultimately makes things safer for patients who need treatment in intensive care units or other high risk settings where contamination could be deadly.

Industrial and Consumer Applications Driving Demand for Reliable Packaging Solutions

Vacuum packaging does more than just keep food fresh or protect medical supplies. It actually works wonders for electronics too, keeping them dry in humid conditions. Car manufacturers rely on it to prevent rust forming on metal parts stored in warehouses. Even clothes shipped across oceans stay protected from moisture thanks to this technology. The manufacturing side has evolved quite a bit lately. Big industrial machines are churning out much tougher plastic films these days that won't tear easily when handling heavy products. Meanwhile regular shoppers see those clear vacuum packs at stores because companies know customers want to see what they're buying before purchasing. With online shopping booming, there's been a real surge in need for better packaging solutions. According to some recent research from Packaging Efficiency Report last year, using durable vacuum packs actually reduces damage during transport by around 40%. That makes sense when we think about how many packages get lost or broken in transit nowadays.

Future Trends: Sustainability and Innovation in Plastic Bag Making Machines

Smart Manufacturing: IoT and Sensors in Next-Generation Packaging Machinery

The latest plastic bag making machines now come equipped with internet-connected sensors and real time analysis tools that really boost their efficiency. What these systems do is constantly monitor things like heat levels, pressure readings, and how thick the film gets during production. They then tweak machine settings automatically which helps slash material waste by around 15 percent without compromising on those all important seals. A recent 2024 report from the Industry 4.0 folks showed something pretty impressive too: factories using these connected machines saw energy consumption drop by about 20% compared to older equipment when running at full capacity. As companies worldwide scramble to meet growing demands for smarter packaging solutions, this shift towards intelligent manufacturing makes perfect sense both economically and environmentally speaking.

Shift Toward Biodegradable and Recyclable Food Packaging Materials

According to recent research from PIRA International in 2024, around two thirds of shoppers now prefer environmentally friendly packaging options. That's why many manufacturers have started using biodegradable materials such as PLA and PBAT for their products. The good news is that today's machinery works just fine with these alternative materials while still maintaining strong seals. What's even better? These new films actually break down about 90 percent quicker than regular plastic waste. There's another development worth mentioning too. Companies are finding ways to blend recycled PET into their production processes successfully. This approach cuts down on carbon emissions by roughly 40% for each individual bag when compared to making them from brand new plastic. Some big names in the industry are already experimenting with cutting edge technology to create compostable vacuum storage bags that don't compromise food freshness or longevity.

Balancing Cost-Efficiency With Environmental Responsibility in B2B Packaging

The manufacturing sector struggles to find common ground between going green and staying profitable, but there are ways to bridge this gap through smart equipment investments. Take modular bag making machines for instance. These allow companies to gradually introduce eco-friendly tech without overhauling entire operations. Some facilities have started installing solar powered heaters which cut down on electricity bills by around 20% per machine according to GreenTech Packaging's 2024 report. When manufacturers switch to machines designed specifically for thin yet strong biodegradable materials, they actually save money too. The cost difference adds up fast—about $15 savings on average when producing 1,000 bags instead of traditional plastic. What really makes a difference though is when companies implement recycling systems right alongside their production processes. One major vacuum packaging plant reduced waste disposal fees by 40% after setting up an internal recycling loop that turns scrap material back into usable product components.

FAQ Section

What materials are commonly used in vacuum-sealed plastic bags?

Vacuum-sealed plastic bags are typically made using polyethylene (PE), polypropylene (PP), and multilayer combinations like PE/EVOH/PE, known for their flexibility and barrier properties.

How does vacuum sealing help in food packaging?

Vacuum sealing removes oxygen, slowing down microbial growth and preserving food 3 to 5 times longer while maintaining flavor and texture.

What are the sustainability trends in plastic bag manufacturing?

There is a shift towards biodegradable and recyclable materials like PLA, PBAT, and recycled PET to reduce environmental impact while maintaining strong seals.

How are quality checks conducted in the production of vacuum-sealed bags?

Quality checks include thickness uniformity, seal integrity tests using pressure decay methods, and cyclic fatigue testing to simulate long-term storage stress.

Table of Contents

- How Plastic Bag Making Machines Enable High-Quality Vacuum Sealing

- Core Features of a Vacuum-Optimized Plastic Bag Making Machine

- From Resin to Ready-to-Use: The Production Process of Vacuum Packaging Bags

- Applications and Industry Demand for Vacuum-Sealed Plastic Packaging

- Future Trends: Sustainability and Innovation in Plastic Bag Making Machines

- FAQ Section