How Plastic Bag Making Machines Meet Industrial Packaging Demands

The critical role of plastic bag making machines in heavy-duty packaging

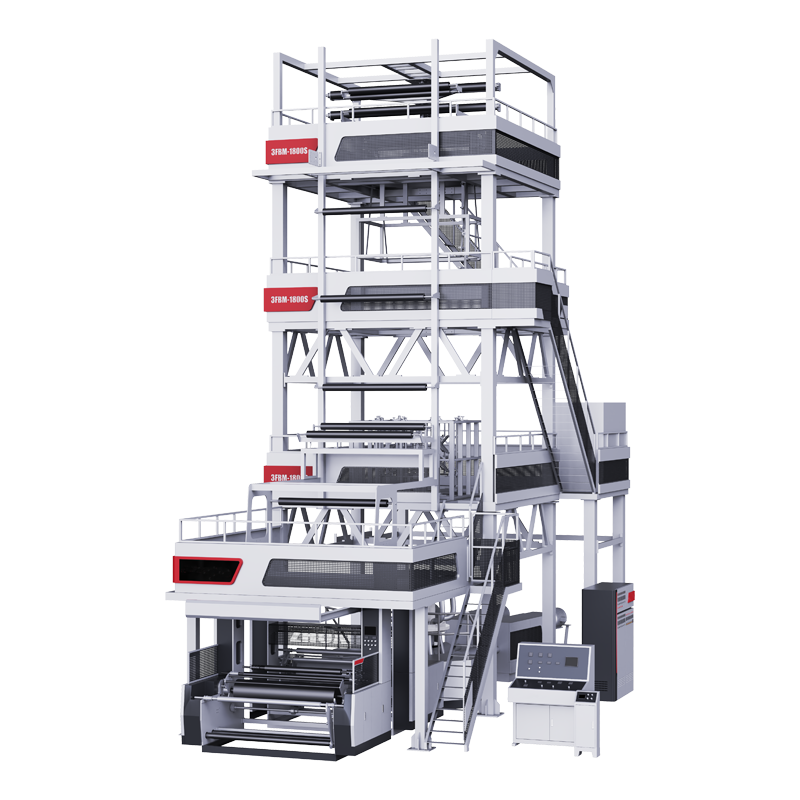

Industrial plastic bag makers are keeping up with growing needs by churning out strong bags that can handle weights between 25 to 50 kilograms thanks to some pretty good engineering work. These machines typically employ blown film extrusion techniques to produce multi-layer polyethylene films around 0.3 to 0.5 millimeters thick, which gives them tensile strength well above 30 MPa. Market numbers look impressive too, hitting around $3.1 billion globally last year as demand kept climbing at roughly 24% per year, especially from folks working in logistics and farming industries. Most modern setups come equipped with servo-driven sealing technology that keeps seams consistent about 98% of the time, something that matters a lot when transporting heavy chemicals or storing building supplies safely.

Key applications across logistics, agriculture, and construction industries

- Logistics: Anti-static courier bags produced at over 300 units per day per machine reduce puncture rates by 60% compared to manual methods

- Agriculture: UV-resistant films from specialized extruders protect 1-ton grain sacks from degradation in tropical climates

- Construction: High-speed machines produce 1,200–1,500 FIBCs (Flexible Intermediate Bulk Containers) hourly, tailored for abrasive materials like cement

A recent industrial packaging study found that 72% of manufacturers now prioritize machines compatible with recycled polymers, aligning with global sustainability mandates for heavy-duty use.

Film Extrusion: The Foundation of Industrial-Strength Bag Production

Blown Film Extrusion: Why It Dominates Heavy-Duty Plastic Bag Manufacturing

Around 68% of all industrial plastic bags worldwide come from blown film extrusion because this method just works better when it comes to making things that last longer and bend without breaking. The technique basically takes hot melted polyethylene and blows it into a bubble shape, which aligns molecules in multiple directions across the material. This alignment actually makes the final product about 40% tougher against tearing than what we get from flat die methods, though results can vary depending on conditions. Another big plus is that blown film creates continuous tubes without seams, which is why many manufacturers prefer it for heavy duty applications like protective covers for buildings or those massive bulk bags that hold up to 2000 pounds worth of stuff.

From Polyethylene Resin Pellets to Continuous Film Production

The manufacturing process starts when polyethylene resin pellets get heated to around 190 to 230 degrees Celsius inside those big barrel extruders we all know about. Special barrier screws help create a better mix of materials, cutting down on those pesky unmelted bits by almost 90 something percent. Once melted, the polymer moves through these ring-shaped dies where operators adjust air pressure settings to control how big the bubbles become and set the final film thickness somewhere between 80 and maybe 250 microns thick. After that comes the chill rolls which cool everything down pretty fast, often running over 25 meters per minute. Most plants keep these machines going nonstop day after day because logistics companies need their plastic films without interruption.

Comparing HDPE, LDPE, and LLDPE for Industrial Bag Performance

| Polymer | Tensile Strength (MPa) | Puncture Resistance | Common Industrial Applications |

|---|---|---|---|

| HDPE | 25–32 | Moderate | Chemical drums, pallet covers |

| LDPE | 8–15 | High | Food-grade liners, shrink wrap |

| LLDPE | 15–25 | Exceptional | Sandbags, FIBCs (bulk bags) |

HDPE is preferred for moisture-barrier applications due to its crystalline structure, while LLDPE excels in agricultural sacks requiring high stretch capacity (up to 300%). Metallocene-catalyzed LLDPE allows 15% thinner films without sacrificing strength–boosting efficiency for machine operators.

Converting Film into Durable Industrial Bags: Sealing, Cutting, and Automation

Precision Cutting and High-Strength Sealing Techniques for Load-Bearing Bags

In industrial settings, machines transform continuous rolls of film into durable sacks through synchronized cutting and sealing operations. The servo-controlled blades maintain an accuracy range of plus or minus 0.5 mm when it comes to width measurements, which is essential for getting those FIBC dimensions right. For heat sealing, most systems employ multi-stage bars operating between 150 degrees Celsius and 220 degrees Celsius. These temperatures produce seams with strength ratings exceeding 35 Newtons per square millimeter for both HDPE and polypropylene materials. Such strength ensures the bags can handle dynamic loads approaching 2,000 pounds without failure. Another benefit comes from offset cutting patterns that cut down on wasted material compared to traditional manual methods. Industry reports indicate this approach typically saves around 15% in material costs, making it a smart choice for manufacturers looking to optimize their production processes while maintaining quality standards.

Advanced Thermal and Ultrasonic Sealing Technologies for Structural Integrity

Modern systems utilize dual sealing technologies:

- Impulse sealing for variable-thickness films (80–250 microns)

- Ultrasonic bonding for laminated, moisture-barrier materials

A 2024 polymer adhesion study showed ultrasonic systems improve seal consistency by 40% in humid environments typical of agricultural storage. Cross-contour sealing heads maintain 98% integrity even with recycled resin blends containing up to 30% post-industrial waste.

Automated Conversion Units Enabling High-Speed, Consistent Output

Integrated all-in-one plastic bag making machines combine folding, sealing, and cutting in a single 25-meter line, producing up to 240 bags per minute. Machine vision systems inspect 18 quality parameters per bag, including:

| Parameter | Tolerance | Rejection Rate Reduction |

|---|---|---|

| Seal width | ±0.2 mm | 62% |

| Handle alignment | <1° angular offset | 57% |

This automation reduces labor costs by $18.70 per 1,000 bags and maintains defect rates below 0.3% in construction-grade sack production.

Quality Assurance: Testing Materials and Structures for Industrial Reliability

Ensuring uniform thickness and tensile strength in PE and PP films

Laser-guided monitoring ensures film thickness accuracy within ±0.005 mm–critical for bags supporting over 2,500 lbs–meeting ASTM D882-18 standards. Automated tensile testers verify elongation (300–600%) and tear resistance (up to 40 N/mm²), ensuring compliance with ISO 527-3 protocols for heavy-duty sacks.

Standardized testing protocols for FIBCs and bulk-handling sacks

The International Safe Transit Association (ISTA) requires seven-stage testing for FIBCs, including:

- Vibration testing: Simulating 1,500-mile transport cycles

- Stacking compression: 6:1 safety factor for 8-meter-tall palletized loads

- UV degradation resistance: 2,000-hour accelerated weathering trials

These procedures reduce field failure rates by 62% compared to non-tested alternatives (ISTA 2022).

Balancing cost-efficiency with long-term durability in industrial applications

Manufacturers use finite element analysis (FEA) to optimize material usage, reducing polyethylene consumption by 18% while maintaining burst strength above 45 kPa. According to a 2023 Packaging Efficiency Study, this lowers unit costs by $0.12 and extends service life by 30–40 loading cycles in abrasive mining conditions.

Innovations Driving the Future of Plastic Bag Making Machines

Smart Sensors and AI-Powered Monitoring for Real-Time Quality Control

The latest smart sensors combined with AI monitoring can spot defects with around 98.5% accuracy. They're able to detect really tiny changes in film thickness down to about 0.005 mm and check seam strength while production is happening. Compared to what people used to do manually, these systems cut down on wasted materials by roughly 22%. Pretty impressive stuff. What makes them even better is their ability to adapt automatically when there are changes in resin viscosity. This means manufacturers get consistent results whether they're working with regular HDPE or those tricky recycled material blends that so many companies are trying to incorporate these days into their operations.

Energy-Efficient Extrusion Systems Lowering Operational Costs

Next-generation extrusion units consume 18% less energy per kilogram of film produced, thanks to optimized screw designs and servo motors. These advancements comply with 2024 EU Ecodesign Standards and cut energy costs by $12.60 per production hour, all while maintaining throughput above 220 kg/h for industrial-grade PE films.

IoT Integration Enabling Predictive Maintenance in Production Lines

Connected machines transmit operational data to centralized dashboards, predicting bearing failures 72 hours in advance with 89% accuracy. This IoT approach has reduced unplanned downtime by 41% in high-volume facilities, based on production audits across Asian manufacturing hubs.

Sustainable Advancements: Recyclable Materials and Closed-Loop Manufacturing

Leading systems now process recycled polyolefin blends with 35–50% post-consumer content without compromising tensile strength. Closed-loop water cooling and solvent-free adhesive systems enhance environmental performance, achieving 82% resource recovery rates in pilot projects aligned with 2025 circular economy goals.

FAQ Section

What is blown film extrusion?

Blown film extrusion is a manufacturing process where melted polyethylene is inflated into a bubble shape, which creates multi-directional molecular alignment in the final product, enhancing its strength.

How do plastic bag making machines contribute to sustainability?

Modern machines now support recycled polymers and incorporate closed-loop manufacturing processes that optimize material use and enhance resource recovery, aligning with global sustainability mandates.

What are FIBCs?

FIBCs, or Flexible Intermediate Bulk Containers, are large bags designed to hold heavy bulk materials such as grains, sand, or cement. They are commonly used in logistics and construction industries.