How Bag Making Machines Enhance Durability and Waterproof Performance

Technology Advancements in Bag Making Machines That Ensure Structural Integrity

Today's bag making equipment incorporates laser guided alignment systems along with servo driven tension controls which results in seals that are around 34 percent stronger compared to older techniques according to FlexPack data from last year. These machines have adaptive pressure sensors built into them that constantly tweak the sealing force depending on how thick the material is, even down to changes of plus or minus 0.05 millimeters. This helps avoid those annoying weak spots we sometimes see in multi layer film packaging. When it comes to food grade waterproof packaging applications, nearly all high volume production lines these days come equipped with stainless steel parts where materials touch during processing. The stainless steel resists sticking from adhesives and keeps things clean enough for food safety requirements too.

Material Compatibility and Its Role in Producing Strong, Waterproof Packaging

The machines handle some pretty sophisticated stuff these days, including TPU coated nylon and those three layer polyethylene composites. These materials need careful temperature control somewhere around 150 to almost 200 degrees Celsius to get proper bonding right. According to research published last year in material sciences, when welders work with matching polymer mixes they can reach nearly 100% waterproof results. That beats out the old stitched and taped methods by quite a margin actually, something like 73% better performance. And here's another neat feature: RFID tags on the film rolls let the equipment recognize what kind of material it's dealing with automatically. This means the machine adjusts settings on its own so nothing peels apart even when subjected to pressures as high as 50 pounds per square inch.

Integration of Automation for Consistent, High-Quality Output

Modern automated vision systems can check around 1,200 bags every single minute looking for tiny flaws down to just 0.2mm in size. These systems have cut down on waterproofing problems by almost two thirds according to recent industry reports from Packaging Automation Index 2024. Combine them with robotic arms handling materials and smart AI that predicts when parts might fail, and factories see impressive results too. The equipment runs nonstop at about 98.6% uptime which is really important if companies want their products to meet those tough ASTM D3078 requirements for completely sealed packages. What makes this setup so valuable? Well, it drops human mistakes down below 0.02%. That means packages actually hold up under all sorts of rough testing conditions without letting moisture get inside, something that traditional methods simply couldn't handle consistently.

Key Types of Bag Making Machines for Waterproof Packaging Applications

Bottom Seal Bag Making Machines for High-Tension, Moisture-Resistant Packaging

Bottom seal machines strengthen the base of bags through multiple stages of heat sealing, which makes them really good for tough jobs like holding fertilizers or construction materials in sacks. These machines can fuse together three different polymer layers, often HDPE mixed with LDPE, creating seals that hold up to around 18 N/mm² according to ASTM standards. This strength helps prevent seams from breaking when bags get wet or loaded down heavily. The way these machines seal vertically spreads out stress better across the material, so they work well for bags holding between 25 to 50 kilograms without leaking water through the seams.

Side Gusset and Center Seal Machines: Design Flexibility for Diverse Needs

Side gusset machines make those expandable sections through carefully folded pleats, whereas center seal versions actually produce bags with two separate compartments separated by a middle seam. These machines typically run on wedge sealers that maintain heat between around 160 to 200 degrees Celsius, creating seals so tight they can handle all sorts of odd shaped stuff from car components to frozen meals without leaking. A recent packaging industry report from 2023 found that nearly seven out of ten logistics companies now go for these bag designs when shipping electronic goods because they offer just the right kind of moisture control that can be adjusted depending on what needs protecting inside.

Modular Systems and Integration with Blown Film Extrusion Lines

The modular bag making machines work right alongside blown film extruders to produce those 3 to 7 layer laminated films all in one pass through the system. According to FlexPack Con 2024 research, this configuration reduces material handling needs by roughly 40%, which saves time and money. What's really important here is how tight the thickness control stays within plus or minus 0.01 mm. That kind of precision matters a lot because it stops those pesky pinhole leaks from happening. We see these kinds of systems everywhere in the pharmaceutical industry when they make dry powder pouches. For something so sensitive, having absolutely no gaps in the seals isn't just nice to have—it’s absolutely essential for product safety and regulatory compliance.

Material Selection and the Transformation from Film to Finished Bag

Synthetic and Composite Materials for Superior Water Resistance

Engineered materials such as polyethylene laminates and polypropylene composites are central to achieving waterproof performance. In controlled tests, these synthetics demonstrate 98.6% water repellency (Packaging Materials Journal 2023), with multilayer structures combining moisture barriers and abrasion-resistant outer layers. Modern machines can process bio-based composites containing 30–40% recycled content without sacrificing seal strength.

Layered Film Structures and Their Impact on Bag Strength

Alternating polymer layers increase tensile strength by 200% compared to single-layer films. A typical 5-layer configuration includes:

| Layer Position | Material | Function |

|---|---|---|

| Outer | BOPP Film | Puncture resistance |

| Middle 1 | EVOH | Oxygen/moisture barrier |

| Middle 2 | Adhesive Polymer | Interlayer bonding |

| Middle 3 | LDPE | Heat-sealing capability |

| Inner | LLDPE | Flexibility & drop protection |

This structure allows bags to withstand 15–20 psi internal pressure while maintaining water vapor transmission rates below 0.01g/24hr/m².

From Raw Film to Sealed Product: The Continuous Manufacturing Process

Automated systems convert polymer pellets into finished bags through three integrated stages:

- Film Extrusion: Molten material is blown into precise thicknesses (typically 0.08–0.15mm)

- Printing/Cutting: High-resolution UV printers apply branding before servo-driven dies cut film webs

- Heat Sealing: Computer-controlled jaws create 2.5–3.5mm wide seals at 140–160°C to ensure watertightness

Top-tier systems achieve 98.7% first-pass yield at speeds of 120–150 bags per minute, showcasing the synergy between material science and machine precision in waterproof packaging.

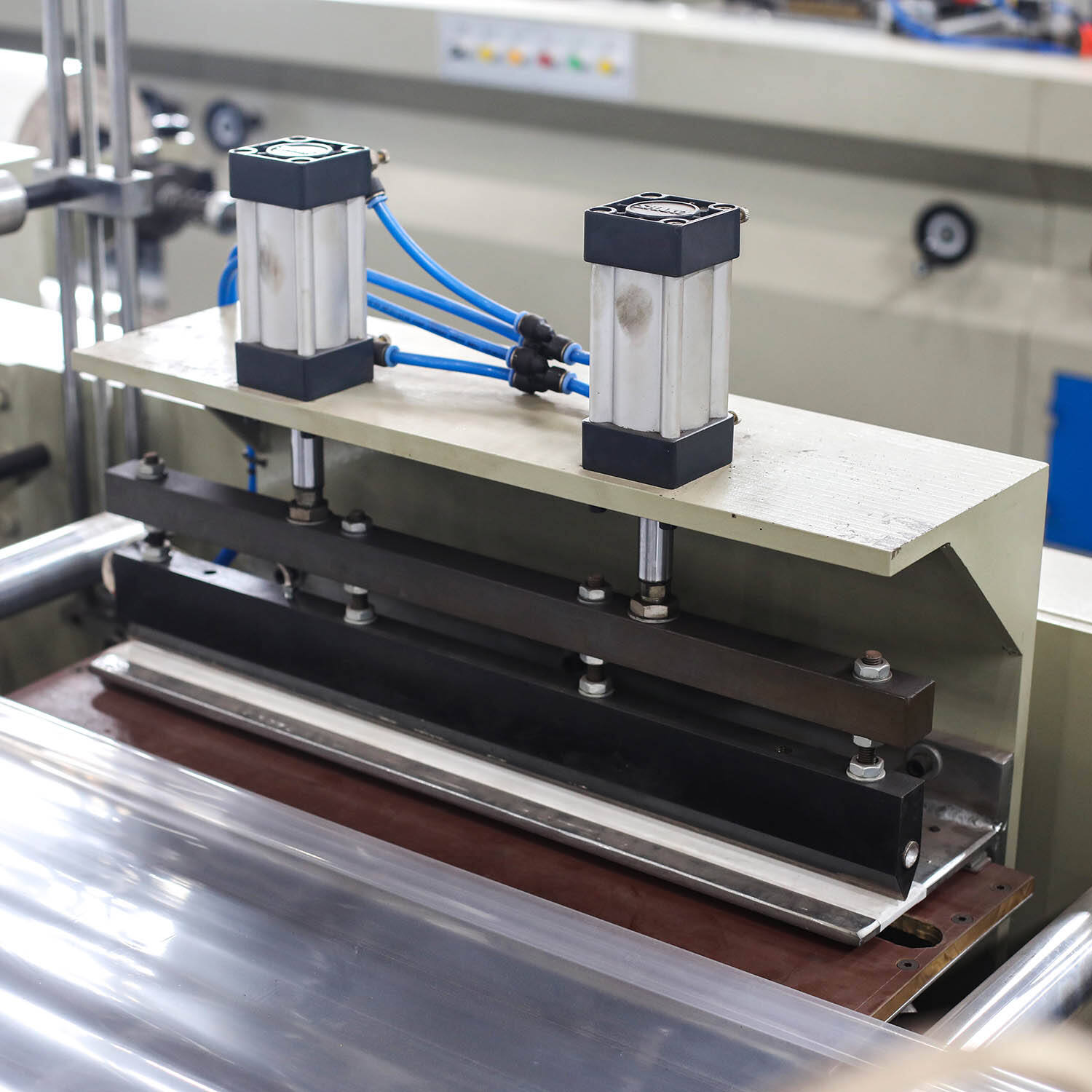

Core Sealing and Cutting Mechanisms in Bag Making Machines

Precision Cutting and Sealing for Uniform Bag Quality

Laser-guided cutting systems and servo-driven seal bars deliver micron-level accuracy, ensuring consistent seam alignment across polyethylene, polypropylene, and multilayer laminates—essential for ISO 9001 compliance. Optical sensors detect thickness variations up to 0.2mm and automatically adjust blade pressure to prevent incomplete cuts or fraying.

Heat Press Technology and Temperature Control for Reliable Waterproof Seals

Multi-zone heat presses with PID controllers maintain ±1°C temperature stability across sealing jaws, even at speeds over 120 bags/minute. This precision reduces seal leakage by 34% compared to conventional thermal systems (Packaging Digest 2023). Dual cooling stations rapidly set heat-activated adhesives in laminated films, enhancing structural integrity.

Automated Sealing Systems to Minimize Defects and Maximize Efficiency

When integrated vision systems work alongside machine learning algorithms, they manage to keep defect rates under half a percent during non-stop operations. The technology watches seal widths between 10 and 25 millimeters for those waterproof needs while also tracking interface pressures from around 15 to 30 pounds per square inch. This allows operators to tweak things as needed without stopping production. What makes these systems really stand out is how they handle materials that stretch differently when temperatures change or humidity fluctuates. This ability to adapt has been getting attention lately, especially after being featured prominently in last year's Flexible Packaging Manufacturing Report from industry experts.

Balancing Production Speed and Seal Integrity in High-Output Environments

The fastest bagging machines out there can handle over 150 bags per minute thanks to something called dynamic pressure profiling. Basically, these machines adjust the sealing force as the production line speeds up or slows down. According to real world testing from several manufacturing sites, when companies fine tune these pressure settings properly, they maintain around 99.8% good seals on their products while getting twice the output compared to older fixed pressure systems. What makes this technology so valuable is the modular design aspect. Manufacturers can switch back and forth between regular straight cut bags and those with extra space at the bottom (gusseted formats) pretty quickly. And guess what? The waterproof qualities stay just as strong during these changes. This flexibility works great for businesses that need to produce packaging for everything from snacks to heavy duty industrial goods all on the same production line.

Testing and Validation of Durability in Automated Bag Production

Industry Standards for Testing Strength, Pressure, and Moisture Resistance

Manufacturers of bag making equipment need to ensure their products comply with both ASTM International guidelines and ISTA standards when it comes to testing for waterproof properties and how well they handle weight. Take ISTA 3E certification as an example. Packaging needs to survive under 75 kilograms of stacked weight while keeping water vapor transmission rates below 0.01%. This is particularly important for items like medicines and food products that spoil easily. The actual testing process shows that modern automated sealing technology can reliably create bonds strong enough to withstand at least 4.5 Newtons per 15 millimeters throughout production cycles running between 100 to 150 bags every minute. These results give manufacturers confidence in their machines' ability to maintain quality even during high volume operations.

Puncture, Drop, and Environmental Stress Testing Protocols

Three-phase validation replicates real-world conditions:

- Puncture resistance: 2.5mm steel probes apply 15N force to test film integrity

- Drop testing: 12 controlled drops from 1.8m simulate warehouse handling

- Environmental chambers: 48-hour cycles alternate between -30°C and +50°C at 95% humidity

These protocols reveal weaknesses in layered films, especially at seal interfaces where 78% of transit failures occur (Packaging Digest 2023). Advanced machines now include inline thickness gauges and thermal imaging to detect micro-leaks as small as 50μm during production.

Case Study: Performance of Machine-Made Waterproof Bags in Real-World Logistics

A Southeast Asian seafood exporter reduced cold-chain packaging damage by 42% after implementing automated validation on their bag making machines. Post-optimization results showed:

| Metric | Before Automation | After Automation |

|---|---|---|

| Seal failure rate | 1.2% | 0.3% |

| Moisture ingress | 0.8g/day | 0.1g/day |

| Average load cycles | 18 | 32 |

Predictive maintenance algorithms extended component lifespan by 200–300 operational hours between replacements, proving that integrated testing enhances both product durability and production efficiency.

FAQs

How do bag making machines enhance the waterproof performance of packaging?

Bag making machines improve waterproof performance by integrating advanced sealing technology such as adaptive pressure sensors, heat press technology, and multi-zone heat presses. These systems ensure strong, reliable seals for materials, effectively preventing moisture ingress.

What materials do bag making machines work with to produce waterproof packaging?

Modern bag making machines handle materials like TPU coated nylon, polyethylene composites, and bio-based composites with significant recycled content. These materials, when properly processed, provide superior waterproof capabilities.

How do automated systems improve the quality of bag production?

Automated systems enhance production quality by using vision systems to detect defects, machine learning algorithms to minimize errors, and dynamic pressure profiling to maintain seal integrity at high speeds. These technologies ensure high-quality output with reduced human errors.

What role do industry standards play in bag making machine production?

Industry standards such as ASTM and ISTA guidelines ensure that bag making machines produce packaging robust enough to handle pressure, moisture resistance, and strength requirements. Adherence to these standards guarantees product reliability and compliance with safety regulations.

Table of Contents

- How Bag Making Machines Enhance Durability and Waterproof Performance

- Key Types of Bag Making Machines for Waterproof Packaging Applications

- Material Selection and the Transformation from Film to Finished Bag

- Synthetic and Composite Materials for Superior Water Resistance

- Core Sealing and Cutting Mechanisms in Bag Making Machines

- Testing and Validation of Durability in Automated Bag Production

- FAQs