How Zipper Bag Making Machines Work: Technology and Core Engineering

What Is a Zipper Bag Making Machine and How Does It Integrate Sealing Mechanisms?

Zipper bag making machines handle the whole process for creating those handy resealable packages. They bring together several steps at once including forming the film, applying the zippers, and then sealing everything properly. The machines attach these little plastic zippers (usually made of either polyethylene or polypropylene) right between different layers of protective film. This bonding happens through heat application or sometimes with ultrasonic technology. Special parts called vertical sealing jaws work alongside horizontal crimpers to make sure the bags are completely sealed against air getting in or out. At the same time, these components keep everything lined up correctly along the zipper track so when someone closes the bag again later, it actually works as intended most of the time.

The Integration of Zippers and Sealing Mechanisms in Bag Production

The process starts when films get unwound into what's called a forming collar, which basically rolls them into this continuous tube shape. At the same time, those little zipper parts come off spools in sync and get stuck onto the film edges using these heated sealing bars that control temperature pretty precisely. Some newer machines take things even further with servo driven actuators that can tweak tension on the fly. This makes better use of materials overall and cuts down on waste quite a bit actually about somewhere between 8 to 12 percent less waste than older mechanical systems according to last year's Packaging Automation Report. Makes sense really because saving material means saving money for manufacturers.

Core Engineering Principles Behind PE Zipper Bag Making Machines

High-speed PE zipper bag machines operate on three foundational principles:

- Material Compatibility: Film thickness (15–200 microns) and melt index must match the zipper material to ensure consistent bonding.

- Precision Timing: Encoder-controlled motors synchronize film feed, zipper placement, and sealing within ±0.1mm tolerance.

- Thermal Management: Dual-zone heating maintains sealing surfaces at 120–180°C, preventing film warping while ensuring strong adhesion.

Durability vs. Speed: Key Trade-offs in Zipper Integration

Durability-focused machines like those in medical packaging typically handle around 40 to 60 bags per minute because they need longer cooling periods between operations. Food grade systems tell a different story though, hitting speeds well above 200 bags per minute thanks to their fast setting seals. According to recent industry reports from Packaging Materials Journal (2023), cutting down on cycle time by about 20 percent actually reduces zipper failures by roughly 15%. The latest IoT systems are changing how manufacturers approach this balance. These smart systems monitor seal layer thickness in real time, adjusting parameters automatically to maintain quality standards across production runs.

Types of Pouch Making Machines: VFFS, HFFS, and Side Seal Systems Compared

VFFS vs. HFFS: Understanding the Differences in Resealable Bag Production

The Vertical Form-Fill-Seal (VFFS) machines are basically everywhere in the world of resealable bag production. These bad boys can crank out something like 220 bags every minute, which works great for stuff like coffee packs and snack wrappers. The process goes like this: first the machine shapes the plastic film around what's called a forming collar, then does all the sealing, filling, and cutting in one smooth motion. According to some industry numbers from last year's Packaging Efficiency Report, this method actually saves around 18 percent on materials when compared to those stiff rigid packages we see sometimes. Now let's talk about Horizontal Form-Fill-Seal (HFFS) systems. These operate side to side rather than up and down, so they tend to be better for bigger or more delicate products like frozen dinners. Sure, HFFS machines can hit speeds of about 290 bags per minute, but there's a catch. They need roughly 30% more room on the factory floor, and honestly just don't work well at all with things like powdered ingredients.

How Pre-Made Pouch Machines Support Zipper-Lock Bag Manufacturing

Pre-made pouch machines specialize in complex zipper-lock designs beyond the capabilities of VFFS or HFFS systems. By heat-sealing preformed pouches with integrated zippers, they deliver:

- 99.8% seal integrity for oxygen-sensitive products

- Compatibility with multi-layer barrier films used in medical and premium food packaging

- Design flexibility for custom features like spouts, tear-notches, and angled edges

Side Seal Bag Making Machines: Role, Features, and High-Speed Applications

Side seal machines emphasize speed and efficiency, producing more than 500 basic resealable bags per minute for industrial applications such as hardware or bulk powders. Their single-seam design consumes 15% less energy than VFFS systems, offering a cost-effective solution for high-volume, minimalistic packaging needs.

Materials and Film Technologies for High-Performance Resealable Bags

Multi-Layer and Barrier Films: Material Selection for Resealable Bag Making Machines

The way we make resealable bags today depends heavily on these special multi-layer films that need to be strong enough to hold contents, create good barriers against outside elements, and still work well during manufacturing processes. Most bags have this typical five layer setup where polyethylene gives them those nice sealing properties, and then there's either EVOH or some kind of metal coating added to stop oxygen from getting in. According to Packaging Analysts from last year, this combination can actually double how long snack foods stay fresh before going stale. These high performance barrier films are becoming really popular now, making up almost seven out of ten packages in the flexible food market. They do such a great job at keeping moisture out, blocking harmful UV rays, and stopping germs from entering that even in factory tests, they barely leak at all – less than half a percent according to recent trials.

| Film Layer | Primary Function | Common Materials |

|---|---|---|

| Outer | Abrasion resistance | BOPP, PET |

| Middle | Gas barrier | EVOH, AlOx coatings |

| Inner | Heat sealing | LLDPE, mPP |

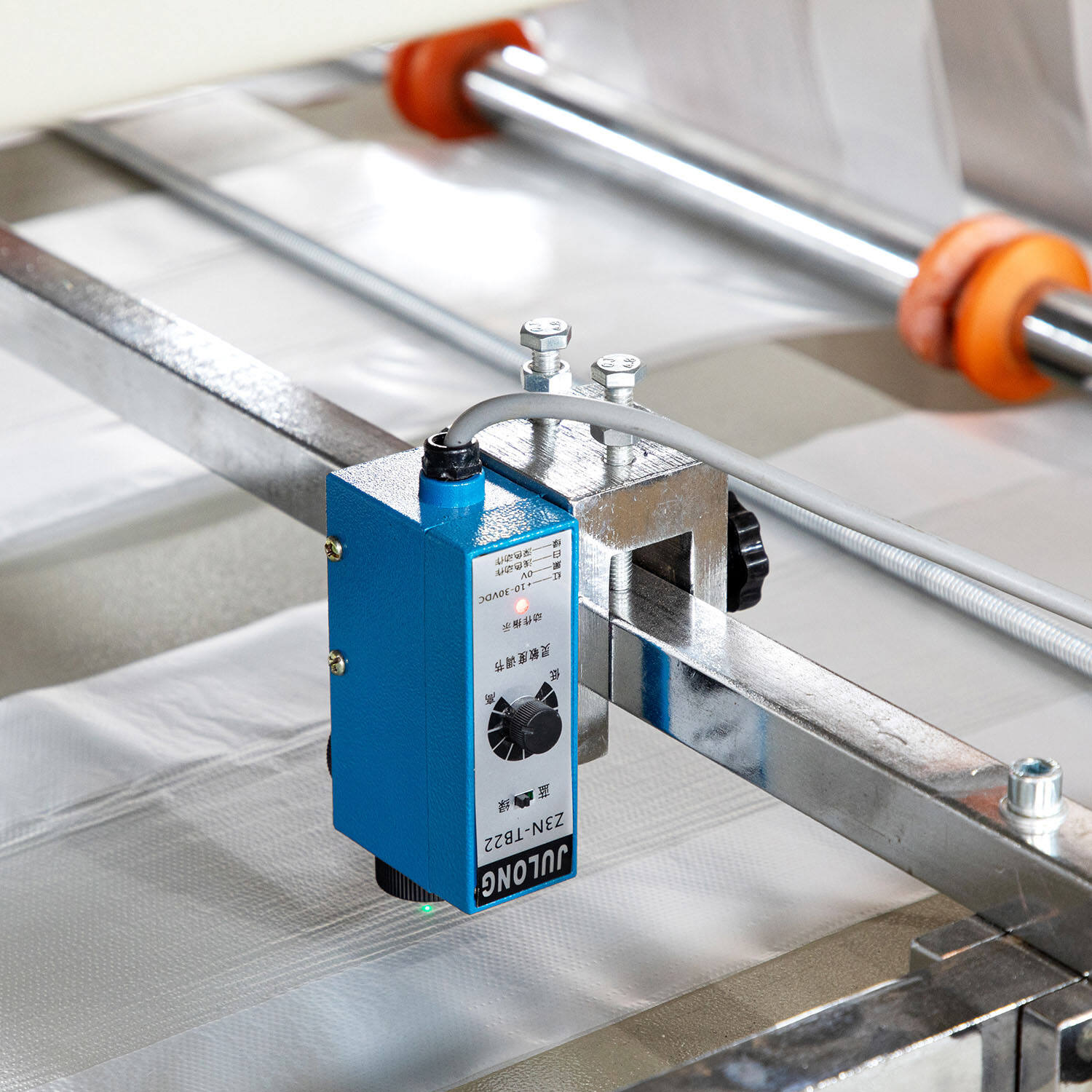

Film Compatibility with Automated Zipper Bag Production

Getting zippers properly integrated into packaging needs films with a melt flow index somewhere around 2 to 10 grams per 10 minutes. This range helps create those consistent welds and strong seals we all want. When it comes to ultrasonic sealing, which is pretty much standard on production lines running faster than 200 bags per minute, there's another consideration. The film material should have no more than 12 percent crystallinity otherwise we start seeing cracks form during processing. Some of the newer equipment on the market actually incorporates artificial intelligence through vision systems these days. These smart systems can spot thickness differences down to plus or minus 2 microns, which makes a big difference when manufacturing those heavy duty bags designed to hold weights exceeding 15 kilograms without failing.

Sustainable Films and Recyclable Zippers: Meeting Eco-Friendly Packaging Demands

Mono material PE films that can actually be recycled have seen their usage jump by about 142 percent since 2022. This growth comes mostly from companies needing to follow rules set out in the EU's Packaging Directive for 2025. Looking at what shoppers want these days shows another trend worth noting. A recent report from the Flexible Packaging Association (2024) found that around eight out of ten consumers look for packages they can seal again and which clearly show how to recycle them. To meet this growing need, many manufacturers now include zippers made from bio based materials derived from sugarcane instead of traditional plastics. But there's still work to do when it comes to compostable options like PLA zippers. These alternatives just don't hold up as well, providing roughly three quarters the strength compared to regular HDPE zippers. Plus, they really struggle during high speed manufacturing processes above about 150 cycles per minute.

Industrial Applications of Resealable Bag Making Machines

Food Packaging: Preserving Freshness with Zipper-Lock Technology

Zipper bag machines that operate automatically are changing how we keep food fresh. These machines seal special multi layer films usually made from PE combined with EVOH to stop air and moisture getting in. The results? Food waste drops around 30 percent when compared with regular packaging according to Packaging Digest last year. When zippers get applied consistently across bags, they create dependable seals that matter a lot for things that spoil easily. Think about snack packs, coffee pouches or frozen meals stored at home. A good seal means these products stay fresh longer after opening.

Medical Packaging: Sterility and Tamper-Evidence in Resealable Solutions

In medical and pharmaceutical applications, automated systems produce resealable pouches with tamper-evident, sterile seals. High-frequency sealing creates closures compatible with gamma sterilization, while transparent film zones allow visual inspection without compromising integrity–critical for regulatory compliance and patient safety.

Consumer Packaging Trends Driving Demand for Resealable Pouches

Resealable pouch demand has grown 24% since 2021 (Smithers 2023), fueled by e-commerce growth and consumer preference for portion control. Modern machines support features like reclosable zippers, tear-notches, and customizable print areas–key selling points in pet food, household cleaners, and personal care categories.

Case Study: A Leading Snack Brand’s Shift to Automated Zipper Bag Making Machine Output

A global snack producer reduced material waste by 18% after switching to VFFS zipper bag machines with integrated applicators. Operating at 160 bags/minute, the system enabled rapid scaling of resealable trail mix pouches, meeting retailer requirements for sustainable, user-friendly packaging.

| Application | Key Requirement | Machine Feature | Outcome |

|---|---|---|---|

| Food Packaging | Oxygen barrier | Multi-layer co-extrusion | 30% longer freshness retention |

| Medical Devices | Sterilization compliance | HFFS with gamma-resistant film | Zero defect rate in 12-month trial |

| Consumer Goods | Reclose functionality | Zipper alignment sensors | 99.8% seal accuracy |

This cross-industry adoption highlights how resealable bag making machines effectively balance speed, durability, and performance.

Future of Bag Making Machines: Smart Automation and Integrated Production Lines

Smart Packaging and Automation: Enhancing Bag Making Machine Efficiency

These days, most high end bag making machines come equipped with AI powered quality control systems that slash material waste around 35% without slowing down production below 500 bags per minute according to The Packaging Institute report from last year. What's really impressive about this tech? It gets those zippers aligned super accurately within just 0.2mm either way. That means manufacturers no longer have to choose between going fast or getting good seals on their products. And let's not forget about the vision systems built right into these machines. They spot issues with film tension almost instantly and fix them before they cause problems. Factories using this setup typically see about a quarter less downtime compared to older models.

Industry 4.0 and IoT: Real-Time Monitoring in Zipper Bag Production

IoT-enabled machines deliver live data on over 15 performance metrics through centralized dashboards. According to a 2024 PMMI study, facilities using real-time production monitoring achieved 22% higher Overall Equipment Effectiveness (OEE) through predictive maintenance. Key improvements include:

| Parameter | Traditional Machines | IoT-Enhanced Machines |

|---|---|---|

| Energy Consumption | 18 kW/hour | 12 kW/hour (-33%) |

| Defect Detection Rate | 87% | 99.6% |

| Changeover Time | 45 minutes | 7 minutes |

The Future: Fully Integrated Lines from Film Extrusion to Finished Zipper Bags

The latest production lines bring together extrusion, printing, zippers, and bag formation all in one seamless operation. When companies stop having to move products between different machines, they cut down on wasted time. What used to take three full days now gets done in less than eight hours for those special order resealable packages. Factories that have already switched to this system say they can adjust designs twice as fast when needed. This speed matters a lot these days since online shoppers keep changing what they want from their flexible packaging options.

FAQ

What are zipper bag making machines?

Zipper bag making machines are automated systems that produce resealable packages by forming film, applying zippers, and sealing.

How do VFFS and HFFS systems differ?

VFFS machines operate vertically, handling smaller packages, while HFFS machines run horizontally for larger items.

Which materials are used for high-performance resealable bags?

Multi-layer films with polyethylene, EVOH, or metal coatings are used for high performance barriers.

How are modern machines integrating eco-friendly packaging solutions?

Recent machines use recyclable materials and bio-based zippers to meet eco-friendly demands.

What advancements have been made in smart automation for bag production?

AI and IoT systems optimize production efficiency and quality, leading to reduced waste and improved seals.

Table of Contents

- How Zipper Bag Making Machines Work: Technology and Core Engineering

- Types of Pouch Making Machines: VFFS, HFFS, and Side Seal Systems Compared

- Materials and Film Technologies for High-Performance Resealable Bags

- Industrial Applications of Resealable Bag Making Machines

- Future of Bag Making Machines: Smart Automation and Integrated Production Lines

- FAQ