What is a plastic bag making machine and how it specializes in clear window bags

Plastic bag making machines transform polymer films into finished products using automated processes designed specifically for adding those see-through windows we all know so well. The equipment comes with special tools that line up these viewing areas just right during production, which matters a lot for retail packages where customers need to actually see what's inside. According to Packaging Digest from last year, today's machines can hit around 0.1mm accuracy in measurements while cranking out over 200 bags every minute. This means manufacturers get lots of bags made quickly with clear windows that don't weaken the overall strength of the packaging.

Key components of machinery used in plastic bag making with window integration

Core subsystems include:

- Precision servo-driven film feeders maintaining tension control within 2% variance

- Dual-heat sealing jaws (160–200°C) with adjustable pressure profiles

- Rotary die-cutters using hardened steel rule blades for window punching

- Vision-guided alignment systems detecting window placement errors down to 0.3mm

Leading manufacturers integrate auto-calibration protocols that adjust cutting parameters based on real-time feedback from infrared thickness sensors and optical scanners.

The role of precision tooling in producing consistent window apertures

The quality of windows produced has everything to do with how well we maintain our die-cutting tools. Even a tiny 0.01mm increase in blade wear leads to about 12% more film tearing when running at high speeds. Modern equipment often features chromium plated cutting dies that have these special self sharpening shapes built right into them. These advanced dies last around three times longer than regular carbon steel ones according to research from the Society of Plastics Engineers back in 2022. Getting this kind of precision matters because it keeps all those window sizes consistent throughout each production run. And let's face it, automated packaging lines simply cannot tolerate much variation. A difference of just plus or minus 1.5mm in bag size will throw off the whole robotic loading system down the line.

From Plastic Film to Finished Bags: The Core Manufacturing Process

Overview of the Plastic Extrusion Process in Film Production

Most modern plastic bag production starts when resin pellets, usually LDPE or HDPE, get dumped into those big heated extruders running between 350 and 500 degrees Fahrenheit. What happens next? The melted plastic gets pushed through special dies that form it into long sheets of film. When companies want those clear window sections on their bags, they have to be careful about what goes into the mix. Too many additives like pigments or fillers will make the plastic look cloudy instead of crystal clear. Some studies show these extra ingredients can cut down transparency by as much as forty percent in the finished product, which is why most manufacturers stick to simpler formulas for those see-through parts.

Blown Film Extrusion: Creating High-Clarity Film for Window Bags

The blown film method dominates high-clarity production, inflating the extruded polymer into a bubble up to 8 meters in diameter. This vertical stretching aligns polymer molecules uniformly, achieving <200 haze units–critical for retail-ready window bags. Bubble stabilization systems maintain consistent thickness (±0.0005") to prevent visual distortion in the final product.

How Film Quality Impacts Transparency and Durability of Clear Window Bags

Three film properties dictate performance:

- Melt Flow Index (MFI): 0.5–2 g/10min for optimal strength/clarity balance

- Tensile Strength: >20 MPa to withstand window die-cutting forces

- Elmendorf Tear Resistance: >600g prevents accidental ruptures

Lower-quality films develop stress whitening at fold points within 50 loading cycles, while premium grades maintain clarity through 200+ cycles.

Environmental Considerations in Plastic Film Extrusion vs. Industrial Efficiency

The conflict between sustainability and production demands emerges in energy consumption metrics:

| Parameter | Traditional Process | Optimized Systems |

|---|---|---|

| Energy Use (kW·h/kg) | 0.65–0.85 | 0.48–0.55 |

| Material Waste | 8–12% | 3–5% |

| Recycled Content | 0–15% | 25–40% |

Advanced extruders now reduce carbon footprint by 18–22% through regenerative drives and closed-loop temperature control, though challenges remain in maintaining clarity with high recycled content.

Sealing, Cutting, and Window Integration in Automated Production

Technologies Behind Sealing and Cutting Plastic Film with Automated Accuracy

Today's plastic bag manufacturing equipment combines heat sealing bars with ultrasonic cutters to get those clean edges and accurate cuts all in one go. The fancier machines come equipped with laser guides for alignment plus servos that keep everything within about half a millimeter tolerance, which means bags come out consistently sized according to the Packaging Trends Report from last year. When it comes to bags with see-through windows, manufacturers rely on infrared tech to profile temperatures right around 120 to 150 degrees Celsius for sealing polyethylene without messing up the window's transparency. These fully automated lines cut down on wasted materials by roughly 18 percent when compared to their semi-automated counterparts thanks to constant monitoring of film thickness during production runs.

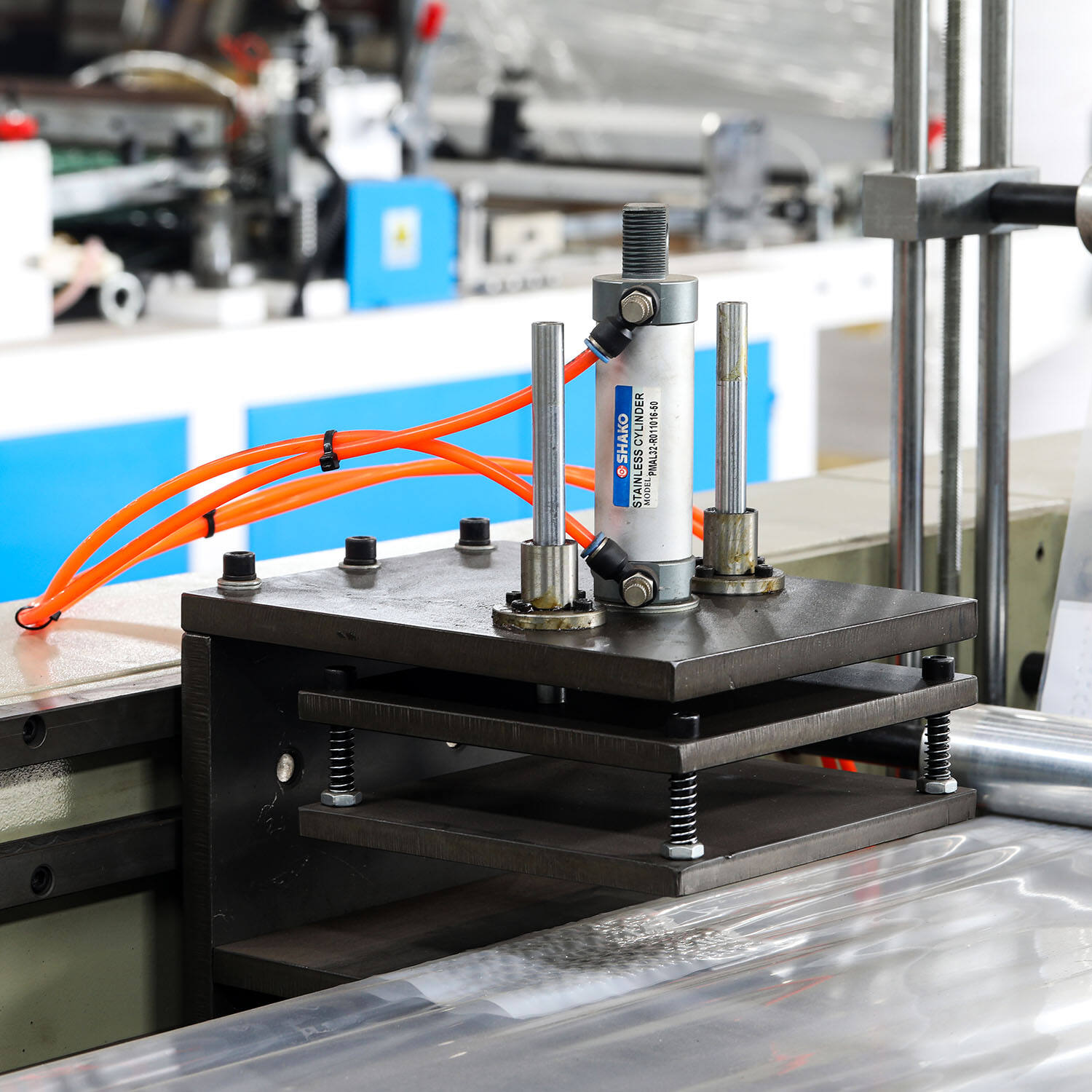

Integration of Die-Cutting Units for Precise Window Formation

High-speed rotary die-cutters integrated into production lines create window apertures at rates exceeding 400 cuts/minute. These units use hardened steel rule dies combined with pneumatic ejection systems to remove window material cleanly. Key factors in precision window cutting include:

- Blade sharpness angle (25–30°) for tear-free edges

- Backing roller durometer (70–80 Shore A) to prevent film deformation

- Synchronized film tension control (±2 N) during punching

Tolerances for window positioning in retail-ready bags now average ±1.5 mm, a 40% improvement over legacy systems (Flexible Packaging Association 2023).

Synchronization Between Film Feeding, Window Punching, and Bag Sealing

Production lines utilize PLC (Programmable Logic Controller) systems with optical encoders to coordinate:

- Film unwinding speed (10–30 m/min)

- Window punch timing (sync within 0.05-second intervals)

- Cross-seal jaw closure sequencing

Advanced phase-locking algorithms compensate for film stretch variations up to 2.5%, while dual-lane inspection cameras verify window placement accuracy before final sealing. Synchronized systems achieve 92% operational equipment effectiveness (OEE) versus 78% in non-integrated setups, translating to over 1,200 retail bags produced per hour in optimized configurations.

Automation and Efficiency in Modern Plastic Bag Making Machines

How Plastic Bag Making Machines Streamline the Conversion Process

Modern plastic bag manufacturing equipment brings together extrusion, printing, and sealing all in one machine setup, so there's no need for workers to handle materials between different production steps. The latest models feature servo controlled feed systems that keep the film properly tensioned throughout the process. According to Packaging Trends 2023 report, these systems cut down on material jams by around two thirds when compared with older semi automatic alternatives. What this means for actual production is manufacturers can churn out those retail quality bags with clear windows at blistering speeds over 120 meters per minute. And despite such high throughput rates, the machines still manage to hold window positioning within just plus or minus 0.2 millimeters tolerance.

Use of Plastic Bag Making Machines in Industrial Production Settings

Big manufacturing operations rely on these machines to keep running nonstop for days at a time with barely any breaks needed thanks to features like automatic roll changes and built-in diagnostics that spot problems before they become major issues. Looking at data from twelve factories back in 2022 reveals something interesting - those places that had installed complete plastic bag production systems saw their monthly output jump by thirty percent while spending forty two percent less on staff expenses. The newer versions come equipped with what's called dual lane processing, which means manufacturers can actually produce multiple bag dimensions simultaneously along the same production line without having to halt operations or switch equipment between runs.

Case Study: High-Speed Production Line for Retail-Ready Clear Window Bags

One European packaging company saw their operations jump to nearly 98% efficiency once they brought in a completely automated plastic bag maker featuring laser guided window punching technology. Their new setup churns out around 23 thousand bakery bags every single hour, complete with built in quality control systems that automatically toss out any bags where the window seal isn't quite right or the printing looks off track. What's even better? They cut down on wasted materials across the year by about 19%, all while still meeting those important ASME B65.2 standards required for safe food packaging applications. The savings add up fast when everything runs so smoothly from start to finish.

Trend: Increasing Adoption of Servo-Driven Systems for Better Control

The latest plastic bag manufacturing equipment features advanced 8 axis servo control systems capable of fine tuning sealing pressure and adjusting cutting timing every 0.01 seconds. These improvements really make a difference in preventing film stretching problems during fast paced window bag manufacturing operations. Especially important for facilities handling biodegradable PLA materials which need very careful temperature control throughout processing. Many plants have seen around 25 percent reductions in power consumption versus older gear driven setups. Defect rates typically stay under 0.1 percent even during massive production runs of over ten million bags at a time, though actual results can vary based on material quality and operator skill levels.

FAQ

How do plastic bag making machines create clear window bags?

Plastic bag making machines transform polymer films into finished products using automated processes specifically designed for adding see-through windows in bags. These machines utilize special tools to align viewing areas accurately during production.

What are the key components of a plastic bag making machine?

Key components include precision servo-driven film feeders, dual-heat sealing jaws, rotary die-cutters, and vision-guided alignment systems to maintain consistent quality and accurate placement of windows.

How does the extrusion process impact window bags?

The extrusion process forms resin pellets into long sheets of film, carefully controlling additives to ensure clarity. Blown film extrusion aligns polymer molecules for high-clarity film essential for window bags.

What technologies are involved in bag sealing with windows?

Modern machines combine heat sealing bars and ultrasonic cutters for clean edges and accurate cuts. They use infrared tech for controlled sealing temperatures, crucial for maintaining window transparency.