High-Speed Performance of Flexo Printing Machines in High-Volume Production

Measuring Real-World Output: Inline Flexo Printing Speed and Throughput

Today's flexo printing machines run at speeds over 600 feet per minute, which is roughly twice what older models managed between 150 and 300 fpm. At these faster rates, printers can crank out thousands of impressions each hour, meeting the needs of big production runs without breaking a sweat. What really matters in practice is having everything happen inline all at once. When printing, laminating, and cutting take place together on one machine, it cuts down on those frustrating stop-and-go delays that slow things down. The ink stays consistent throughout long print jobs thanks to those fancy anilox rollers and chambered doctor blades we've been talking about. This means less wasted material when companies need to rush through orders for seasonal products or meet strict deadlines for items like flexible packaging, adhesive labels, or corrugated boxes.

Advanced Automation Technologies Enabling Faster Production Cycles

When servo driven mechanics work alongside integrated vision systems and robotic plate changers, they cut down on manual labor by around 40%. Production runs faster while still keeping things accurate. The systems can fix cylinder registration issues as they happen and automatically adjust for problems like thermal expansion or when materials stretch out during operation, even when running at speeds exceeding 300 meters per minute. What really stands out though is closed loop color control. This feature keeps colors consistent throughout the process by changing ink density right there on the fly. Setup times get slashed by almost half, which means machines stay running smoothly through those long shifts and big production runs. Factories end up with better machine availability, less mistakes from operators, and products that maintain their quality standards no matter how much gets produced.

Efficiency Boost with Digital Workflows and Rapid Job Changeover

When digital prepress gets integrated with standard job tickets and automatic press settings, it allows for complete job changes in less than 15 minutes flat. This kind of flexibility means no more making new plates physically or doing all that manual adjusting work, which saves tons of downtime and cuts down on wasted materials. The process becomes even better when paired with those fast drying, high solids inks that let companies start their finishing touches right away after printing something. We're talking about things like cutting rolls apart, adding layers, or applying protective coatings. All told, these digital methods can reduce total production time by around 30 percent give or take. For businesses dealing with lots of different products at once, especially folks who make custom food packages for stores or run big label campaigns for promotions, this speed makes all the difference. They can scale operations without breaking the bank and get products out there much quicker than before.

Sustained Print Quality Through Precision Engineering in Long Runs

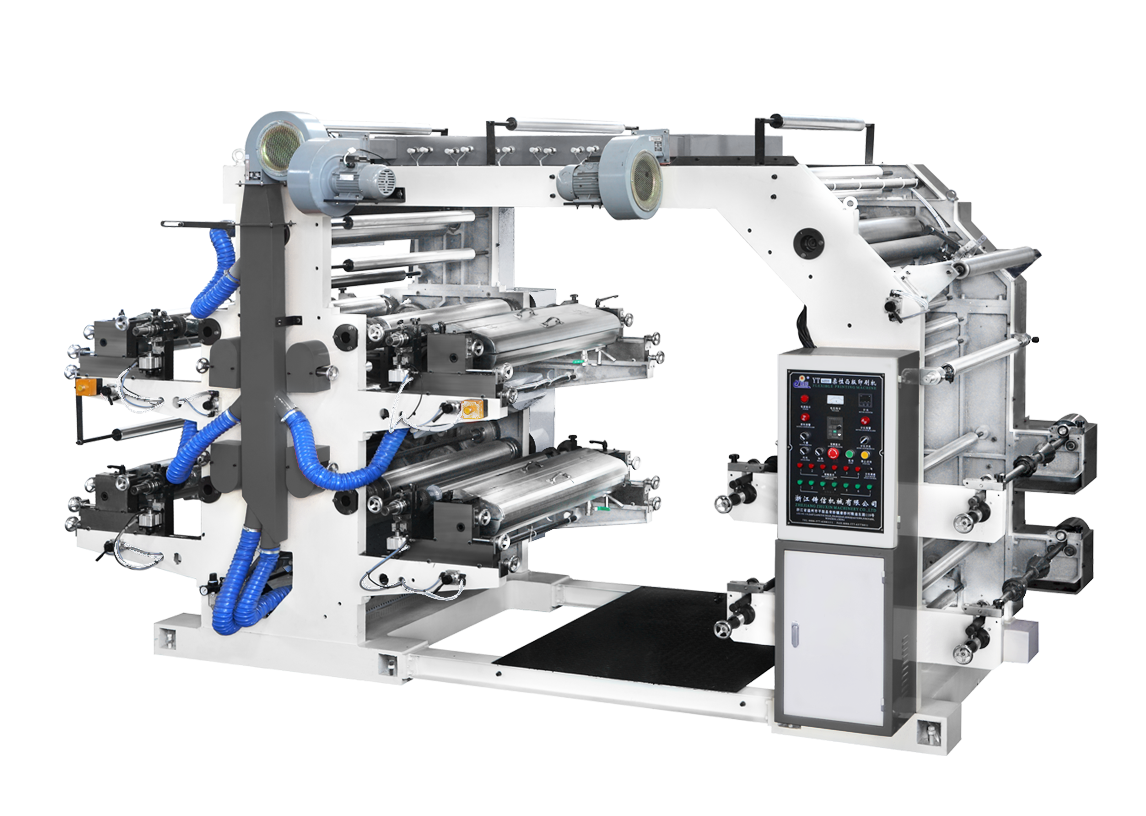

Robust Machine Construction for Reliable Industrial Output

The big flexo presses used for high volume printing rely on solid cast iron frames and toughened steel parts designed to handle non-stop work around the clock. These machines come equipped with finely ground gears, servos that control movement precisely, plus special systems that soak up vibrations. All this hardware keeps colors aligned within microns throughout millions of print runs. Operators don't have to worry about pesky issues like ghost images, ink spreading out too much, or the machine drifting off track after tens of thousands of rotations. According to manufacturing stats, this robust construction cuts down unexpected breakdowns by roughly 30 percent when compared to cheaper models. That means less downtime, fewer wasted materials, and better output rates especially important in industries where labels must meet strict standards like those found in drug packaging or drinks labeling.

Maintaining Consistency: Cylinder Registration and Ink Transfer Stability

The latest closed loop registration systems can actually compensate when materials stretch or expand due to temperature changes. These systems maintain alignment between printing and cutting at around plus or minus 0.1 millimeters even during long production runs of over half a million labels. At the same time, special chambered doctor blades work together with laser engraved anilox rollers to ensure consistent ink coverage all the way across the printing surface. This setup gets rid of those annoying bands, streaks, and color shifts that plague many operations. Industry leaders have seen their color matching results get really close to perfect, with Delta E values below 2 throughout whole production runs. For packaging applications that need strict regulatory approval, this level of consistency matters a lot since both appearance quality and repeatable results just cannot be compromised in these markets.

Cost-Effectiveness and Waste Reduction in Large-Scale Label Printing

Minimizing Downtime and Waste: Reduced Setup Time for High-Volume Runs

When it comes to automated solutions like plate mounting systems, pre-set registration adjustments, and smart web guidance tech, they typically slash setup times anywhere from 40 to maybe even 60 percent. For companies running high volume label production lines, those savings really add up financially speaking. We're talking around seven hundred forty thousand dollars worth of extra productivity each year just from cutting down one minute per day on a single press line according to research from the Ponemon Institute back in 2023. The automated tension controls also help keep materials intact during lengthy production runs. This means less waste due to alignment issues, cutting down spoilage rates by about 18 or so percent. And manufacturers report getting close to 99.5% uptime when making food products too. What's really interesting is how these systems reduce the need for constant human oversight which accounts for roughly thirty percent of all material waste problems in older setups. As a result, first pass yields see significant improvements across the board.

Total Cost of Ownership: Flexo Printing Machine vs. Digital Alternatives

For sustained, high-volume output, flexo printing offers compelling long-term economics:

| Cost Factor | Flexo Printing Machine | Digital Alternative |

|---|---|---|

| Per-unit cost (10k+ units) | $0.003–$0.007 | $0.015–$0.030 |

| Plate/consumable cost | High initial, low recurring | None required |

| Waste rate | 3–5% after optimization | 1–3% |

| Maintenance frequency | Quarterly | Monthly |

Most businesses find they hit the sweet spot around 15,000 linear feet or so when it comes to flexographic printing versus other methods. At this volume level, those lower ongoing material costs start to make up for what was spent initially on equipment. Take something like permanent stock keeping units for drinks bottles or cleaning products - these need labels that last forever basically. Photopolymer plates just keep going strong past a million impressions without any noticeable wear and tear, while digital toner systems are constantly needing new supplies every few thousand prints. When companies actually track their expenses over time, flexo tends to come out ahead by about 23% in total costs across five years. This makes sense considering how tough these plates are, how efficiently they work, and the fact that manufacturers have been scaling them up successfully in factories for decades now.

Frequently Asked Questions

What are the speed capabilities of modern flexo printing machines?

Modern flexo printing machines can operate at speeds exceeding 600 feet per minute, significantly faster than older models which ranged between 150 and 300 fpm.

How do advanced automation technologies improve production cycles?

Advanced automation technologies like servo-driven mechanics and integrated vision systems reduce manual labor by about 40% and ensure production accuracy even at high speeds, leading to better machine availability and fewer operator errors.

Why is digital workflow integration important in flexo printing?

Digital workflow integration enhances efficiency by allowing rapid job changeovers, reducing total production time, and cutting down on material waste, which is crucial for businesses handling diverse products.

What makes the construction of flexo printing machines reliable?

Flexo printing machines are built with solid cast iron frames and toughened steel parts to handle continuous operations, ensuring color alignment and reducing unexpected breakdowns compared to cheaper models.

How do flexo printing machines ensure print quality and consistency?

These machines utilize closed loop registration and chambered doctor blades to maintain precise alignment and consistent ink coverage, achieving close-to-perfect color matching with Delta E values below 2.

Table of Contents

- High-Speed Performance of Flexo Printing Machines in High-Volume Production

- Sustained Print Quality Through Precision Engineering in Long Runs

- Cost-Effectiveness and Waste Reduction in Large-Scale Label Printing

-

Frequently Asked Questions

- What are the speed capabilities of modern flexo printing machines?

- How do advanced automation technologies improve production cycles?

- Why is digital workflow integration important in flexo printing?

- What makes the construction of flexo printing machines reliable?

- How do flexo printing machines ensure print quality and consistency?