Silk Screen and Heat Transfer Printing: Compatibility with Bag Making Machines

Silk Screen Printing for Durable, Cost-Effective Designs on Polypropylene and Non-Woven Materials

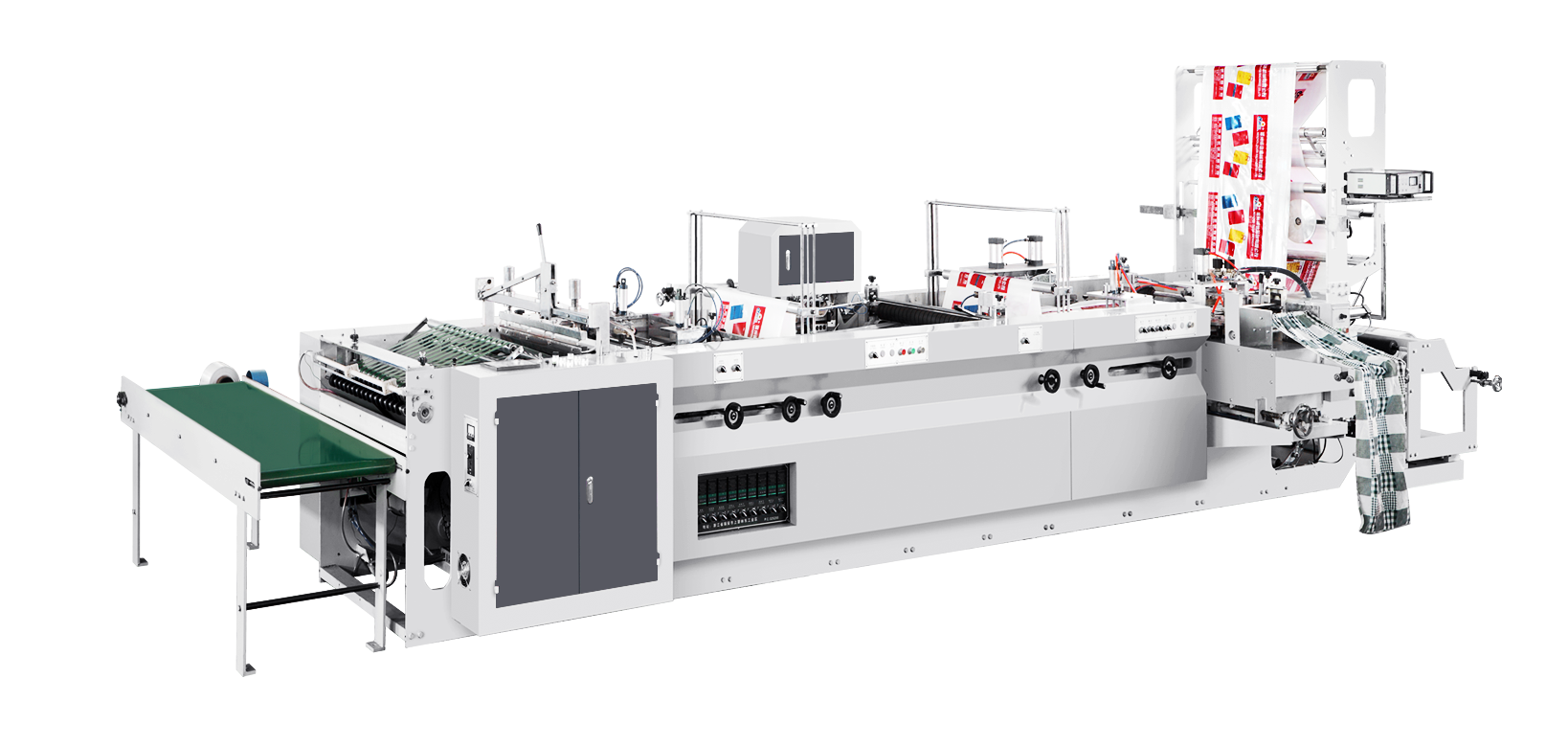

Screen printing creates really opaque, durable graphics that work great on those promotional bags we see everywhere these days, especially ones made from polypropylene or those non-woven fabric types. The technique works by pushing ink through special mesh screens which gives the prints that nice crisp look that can stand up to all sorts of wear and tear. We've seen these kinds of prints hold up pretty well on those reusable grocery totes people keep bringing back to stores, as well as on the heavier duty carry bags retailers hand out during sales events. Some research from last year in the packaging field showed that most screen printed bags still look about 78% as clear after being used over 500 times. What makes screen printing so popular for big orders is how it plays nicely with automated bag manufacturing equipment. Companies don't have to stop production for long periods when changing screens between different designs, which saves time and money on those massive corporate branding campaigns they run throughout the year.

Heat Transfer Printing for Full-Color, Detailed Graphics and Its Limitations on Synthetic Fabrics

Heat transfer printing works really well for creating those lifelike images and smooth gradients we see so much these days. The colors stick pretty close to what's on screen too, around 95% accurate when printed on polyester stuff. Great for detailed logos that need to stand out. But watch out with some synthetics like PE coated non wovens. The ink tends to fade faster there, about 30% quicker than regular screen prints when exposed to sunlight. That can be a real problem for outdoor applications. Machines have gotten better lately though, with synchronized heat presses now able to handle transfers at about 60 bags a minute. Still, the price per item remains higher than other methods, so most businesses find this approach better suited for smaller batches rather than big volume orders where cost becomes a bigger concern.

Comparing Durability and ROI: Silk Screen vs. Heat Transfer for Promotional Bag Campaigns

| Factor | Silk Screen | Heat Transfer |

|---|---|---|

| Durability | 5+ years outdoors | 2-3 years indoors |

| Setup Cost | $800-$1,200 per design | $200-$500 per design |

| Best For | Solid logos, bulk orders | Complex graphics, small batches |

For campaigns exceeding 500 units, silk screen printing offers 40% lower costs, while heat transfer becomes economical for runs under 250 units. According to a 2024 circular economy report, screen-printed PP bags achieve a 92% reusability rate, significantly outperforming the 67% reusability of heat-transferred polyester variants.

Emerging DTF and Digital Printing Technologies in Bag Production

DTF (Direct to Film) Printing for Versatile, Vibrant Prints Across Diverse Bag Materials

Direct to Film (DTF) printing lets businesses print vibrant, full color designs across many different materials including things like polyester fabrics, cotton mixtures, woven polypropylene, even recycled PET plastics all while keeping the prints durable enough for regular use. What sets DTF apart is how its special transfer film actually sticks to rough or uneven surfaces where other printing techniques just fail because they work best only on certain kinds of fabric. According to some recent testing from last year, printed shopping bags made with DTF technology kept about 94 percent of their original bright colors even after being washed fifty times. That kind of lasting quality makes these bags particularly good options when companies want to create long lasting promotional items that people will actually keep using instead of tossing aside after one trip to the store.

Challenges in Integrating DTF With High-Speed Bag Making Machines

The versatility of DTF is undeniable, though getting it to work properly with rotary bag machines running anywhere from 150 to 300 bags a minute demands some pretty sophisticated ink curing technology. The good news is these fast drying DTF inks typically set within 8 to 12 seconds compared to regular inks that take over 25 seconds, which helps keep production moving along. Still, there's this ongoing problem with how well the printed film sticks to those gusseted sections of bags, something many operators still struggle with daily. And let's not forget the time factor either. When companies switch back and forth between DTF printing and traditional heat transfer methods, they're looking at an extra 15 to 20 percent in setup time just because all those temperature settings need adjusting each time.

Single-Pass Digital Printing Advantages for High-Volume Plastic Bag Runs

When ordering more than 50,000 polyethylene or polypropylene bags, companies can cut down on wasted materials by about a third when they switch from traditional screen printing to single pass digital printing combined with inline bag machines. The whole process works as one seamless unit where printing happens at the same time as sealing, which means production lines can crank out around 600 bags every hour without sacrificing quality. What's really important here is keeping those tiny details right - something like 0.2 millimeters matters a lot when it comes to making sure barcodes and QR codes stay readable on store shelves. Clear markings aren't just nice to have; they're practically required these days for proper inventory tracking across different retail channels.

Material and Machine Compatibility Across Paper and Plastic Bag Formats

Printing Methods for Paper Bags: Flexo, Offset, Digital, and Screen Printing Options

Today's bag making equipment comes with support for several different printing approaches when working with paper materials. Flexo printing remains the go to choice for mass production runs because it works so well with quick drying inks on both kraft and coated paper types. For those fancy retail packages that need extra detail, offset printing is still king when dealing with laminated stock options. Digital printing has opened up new possibilities too, letting companies customize recycled paper bags as needed rather than running big batches. And let's not forget about screen printing which handles heavier stuff like white cardboard really well thanks to those thick opaque ink layers. Most top manufacturers are starting to install machines with swap out print heads these days, so switching between printing methods doesn't mean stopping production altogether anymore.

Common Paper Materials: Kraft, Coated, Laminated, Recycled, and White Cardboard

| Material | Key Properties | Best Use Cases |

|---|---|---|

| Kraft | Biodegradable, moisture-resistant | Grocery, bulk item packaging |

| Coated | High ink adhesion, grease-proof surface | Food service, cosmetics |

| Laminated | Waterproof, tear-resistant | Premium retail, electronics |

| Recycled | 30-100% post-consumer content | Eco-conscious promotions |

| White Cardboard | Rigid structure, printable both sides | Gift boxes, luxury shopping |

Matching Plastic and Paper Materials with Optimal Printing and Bag Making Machine Setups

Most plastic bags get printed using heat transfer methods on polyethylene film, which needs careful temperature management around 120 to 180 degrees Celsius. When working with different paper types, machine operators have to tweak tension rollers and folding guides as they switch from light weight recycled paper at about 80 grams per square meter to heavier cardboard that's closer to 300 grams. According to a recent industry report from 2023, roughly 78 percent of companies running hybrid bag making equipment saw their waste drop by about 22% thanks to automatic adjustments made during transitions between paper and plastic materials. These synchronized printing systems can keep print alignment within half a millimeter even over large production runs exceeding ten thousand units, so brands stay looking consistent no matter what material is being used, though there are still some challenges with very thin papers occasionally causing minor registration issues.

FAQ

What are the main benefits of silk screen printing for bags?

Silk screen printing provides durable, opaque graphics that are resistant to wear and tear, making it suitable for polypropelene and non-woven materials. It is cost-effective for large orders and compatible with automated bag manufacturing equipment.

Why is heat transfer printing not ideal for large volume orders?

Heat transfer printing tends to be more costly per item, making it better suited for small batches with complex graphics rather than large volume orders. It also requires careful consideration of material compatibility as inks can fade faster on certain synthetics.

What makes DTF printing stand out in bag manufacturing?

DTF printing is versatile and vibrant, adhering to varied materials including uneven surfaces. It is known for retaining color quality even after multiple washes, though it takes sophisticated ink curing technology to work with high-speed bag machines.

How does single-pass digital printing benefit high-volume plastic bag runs?

Single-pass digital printing reduces material waste and integrates seamlessly with inline bag machines, allowing for precise and efficient high-speed production without compromising quality.

What considerations are there when integrating printing methods with hybrid bag setups?

For hybrid bag setups, operators need to manage temperature and adjust machine settings for different materials. Automation helps in reducing waste and maintaining alignment, though thinner papers can pose registration challenges.

Table of Contents

- Silk Screen and Heat Transfer Printing: Compatibility with Bag Making Machines

- Emerging DTF and Digital Printing Technologies in Bag Production

- Material and Machine Compatibility Across Paper and Plastic Bag Formats

-

FAQ

- What are the main benefits of silk screen printing for bags?

- Why is heat transfer printing not ideal for large volume orders?

- What makes DTF printing stand out in bag manufacturing?

- How does single-pass digital printing benefit high-volume plastic bag runs?

- What considerations are there when integrating printing methods with hybrid bag setups?