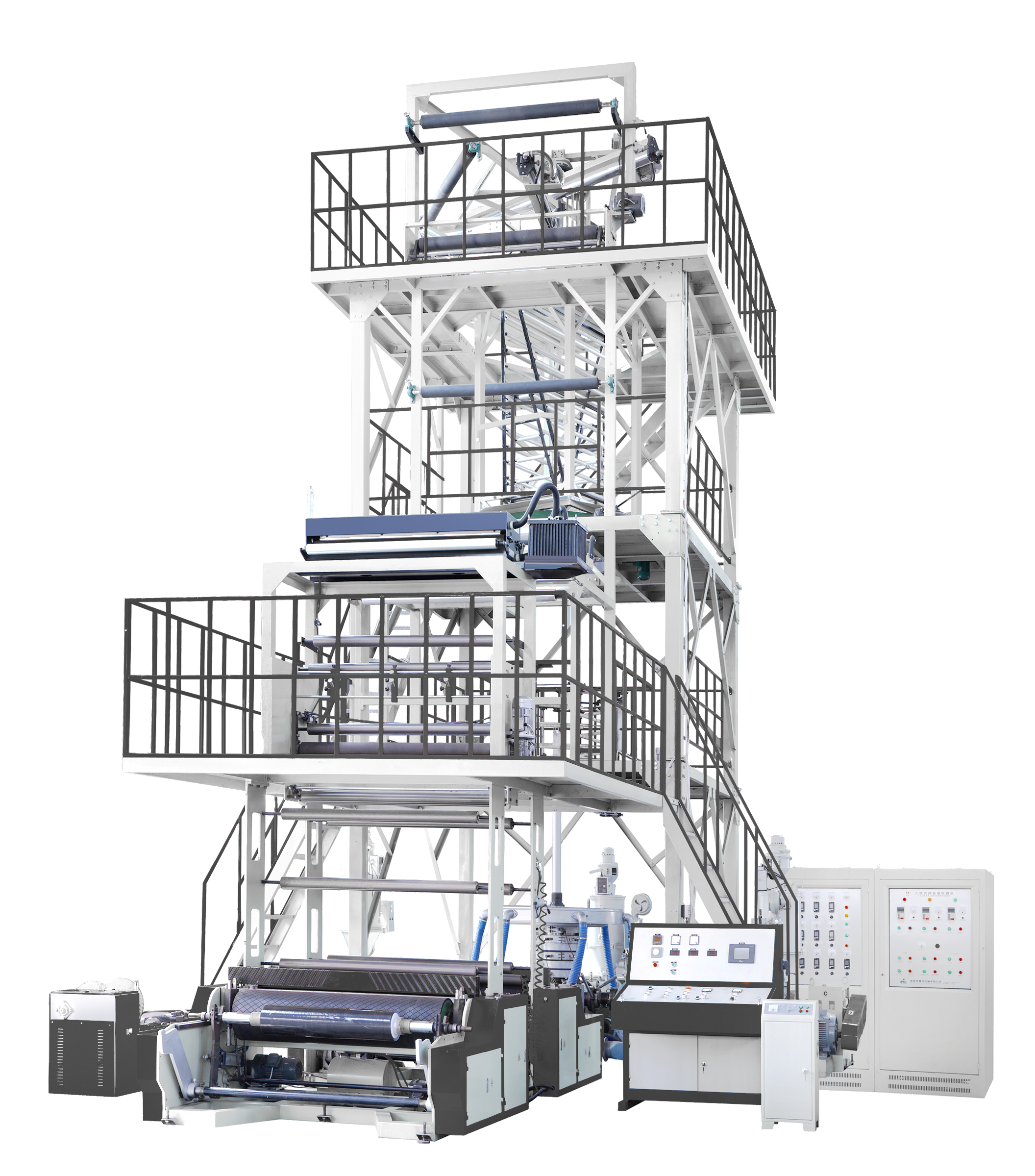

Blown Film Extruder Systems

Blown film extruders in today's film blowing machines play a key part in turning raw plastics into those thin films we see everywhere. A standard system actually has three main parts: the feed section where everything starts, then comes the compression area, and finally there's the metering section. Each part does something important for managing how the melted plastic flows and what pressure it's under. The feed section basically gets things going by making sure the machine gets a steady stream of material. When stuff moves along, the compression zone takes over to melt everything properly and mix it all together. And last but not least, the metering section controls exactly how much molten plastic goes to the die head, which ultimately decides just how thick or thin the final film will be.

The versatility of these systems is pretty amazing actually. They handle all sorts of materials including polyethylene and polypropylene, which means manufacturers can churn out different types of plastic films for countless applications across industries. Extruder tech has come a long way lately too. Factories are seeing real gains in how efficiently they run their operations while cutting down on wasted material during production. Industry data shows that better energy usage combined with smarter material handling has boosted overall efficiency by around 20% in many cases. Modern film blowing machines therefore offer both environmental benefits and financial advantages for businesses looking to stay competitive without breaking the bank, something that fits well with what most companies want these days when it comes to going green.

Die Designs for Precision Thickness

When making quality films, how we design the dies really matters if we want even thickness throughout. Basically, the die shapes the melted plastic as it comes out, which affects both how thick and what kind of properties the final film has. There are several common types out there, but two stand out most: spiral dies and T-dies. Spiral ones tend to spread the material around pretty well, so the film ends up with pretty much the same thickness everywhere. T-dies get praised a lot because they make it easier to tweak the width of the film during production runs. Some manufacturers swear by one type over the other depending on their specific needs.

These design choices really affect how good the final film turns out. When manufacturers get the die right, it makes all the difference for both how strong the film is structurally and how it looks when finished. Most companies need their products to pass pretty strict quality checks anyway. Research from folks working in plastics shows something interesting too. Better die designs actually cut down on variations during production by about 15%. That matters because nobody wants inconsistent batches rolling off the line. For anyone running a plant, this kind of consistency saves time and money while keeping customers happy.

Advanced Cooling and Haul-Off Mechanisms

Following extrusion, advanced cooling systems are crucial for maintaining the film's integrity. Effective cooling ensures the film sets properly, minimizing defects such as sagging or uneven thickness. These systems typically employ air rings or water baths to control the cooling rate, thus preserving film quality.

The haul off mechanisms play a vital role in pulling cooled film away from the extruder without causing any damage during the process. Some advanced setups use dual draw systems that really make a difference in how films are handled throughout production, cutting down on waste materials substantially. When companies get their cooling and haul off processes just right, they see better film quality along with much faster production speeds. According to industry reports, properly adjusted cooling systems alone can cut operational expenses by around 25%, plus increase overall manufacturing output. For plant managers watching those bottom lines closely, these efficiencies mean being able to react faster when customer demands shift and still keep prices competitive in the marketplace.

Tailored Configurations for Packaging Demands

Blown film machines come in all sorts of setups designed for the ever changing world of packaging needs. Manufacturers adjust them to make films at different thicknesses and widths depending on what's needed for packaging jobs ranging from thin grocery bags to thick industrial coverings. Some setups work best with materials like polyethylene or polypropylene, each giving distinct strengths and flexibility properties important for different products. Big name companies across industries have started using these customized options because they really work. Real world tests show how these machine setups boost packaging speed while maintaining quality standards. When companies get their machines right for specific applications, it cuts down on waste during production and keeps products looking good all the way through shipping and handling processes too.

Agricultural Film Production Adaptations

Blown film machines come with special features tailored for making agricultural films such as mulch sheets and greenhouse coverings. What makes these machines unique is their ability to integrate UV stabilizers along with other necessary additives that help films last longer when exposed to varying weather conditions across farms. Farmers need films that can handle everything from intense sunlight to sudden rainstorms without breaking down. According to recent market reports, there's been growing interest in new technologies for producing better quality agricultural films. This trend stems from farmers wanting higher crop yields while also being mindful of environmental impact. After all, most farm films face daily challenges like prolonged sun exposure, fluctuating moisture levels, and accidental damage during installation or maintenance work. That's why having properly adapted machinery remains so important for anyone serious about successful farming operations today.

High-Strength Construction Membrane Solutions

Blown film tech plays a big role in making those tough construction membranes needed for today's buildings. Builders look for stuff that can last through harsh conditions and still meet all those code requirements. Take a look at different parts of construction work – roofs need protection against rain and sun damage, underground areas require good insulation, and vapor barriers must stop moisture from getting into walls. These membranes really stand up to the test of time and keep structures safe over years of use. Field reports show they perform well across countless projects despite varying weather conditions. What makes them so popular? They're light enough to handle easily on site but strong enough to withstand whatever Mother Nature throws at them, striking that balance between what engineers want and what contractors actually need when putting buildings together.

IoT-Enabled Process Control Systems

When IoT tech gets connected to blown film machines, it completely changes how we monitor and control these processes. Manufacturers who install these smart systems get instant information about how their machines are running and what's happening on the production floor. Take maintenance for example – many IoT setups will actually send warnings when parts start showing signs of wear, so breakdowns happen less often. The numbers back this up too. Most factories that adopted IoT solutions report better returns on investment and run smoother operations overall. What makes IoT really stand out is how it transforms traditional production lines, making them smarter and more responsive to changing conditions without requiring constant manual oversight.

Multi-Layer Coextrusion Capabilities

The multi-layer coextrusion technique really makes a difference when it comes to improving film characteristics for packaging purposes. When manufacturers combine several materials during production, they create films that offer better protection against moisture and gases while also being stronger overall. This matters a lot across many industries but especially so in food packaging applications. Think about how fresh meat stays safe longer in vacuum packs or how snacks remain crisp inside their wrappers thanks to these advanced films. According to recent industry reports, there's been an uptick in demand for such multi-layer solutions over the past few years. Companies are increasingly turning to them because they solve complicated packaging challenges that single layer options simply cannot handle. The result? Businesses gain a real advantage in markets where product preservation and shelf life are critical factors for success.

Energy-Efficient Drive Technologies

Bringing energy efficient drive tech into blown film machines represents real progress for green manufacturing. Variable frequency drives (VFDs) cut down on power usage quite a bit, which means factory owners save money on their electricity bills and leave a smaller carbon mark on the environment. Going green isn't just good for Mother Earth either it makes financial sense too. Companies that have switched to these newer systems are seeing some serious reductions in their energy spend. What's interesting is how this fits right into today's sustainability targets without compromising what comes out of the machine at the end of the day. The plastics industry has been watching this trend closely as they try to balance eco concerns with bottom line realities.

The incorporation of these technological innovations in blown film extrusion not only enhances manufacturing capabilities but also positions businesses at the forefront of industry evolution. Embracing IoT, multi-layer coextrusion, and energy-efficient solutions drives competitiveness and supports sustainable practices, leading to future-ready production environments.

Recycled Material Compatibility Features

The latest generation of blown film machines now works better with recycled plastics, which represents a big step forward for material processing tech. Manufacturers can actually put more recycled stuff into their films these days without messing up the final product's strength or appearance. The plastic industry has been working hard on this because going green isn't just good for the planet anymore it's becoming essential for staying competitive. Consumer surveys show growing demand for eco-friendly packaging solutions across multiple markets. What's interesting is that recent tests have proven films made with recycled content still hit those tough industry performance benchmarks, something that worried many producers just a few years ago.

Closed-Loop Plastic Recycling Systems

Closed loop recycling in blown film manufacturing shows real dedication to cutting down waste while supporting circular economy principles. The way these systems work is pretty straightforward they keep materials moving through the production process again and again, which means less need for brand new plastics all the time. Companies that switch to this approach save money on raw materials and slash plastic waste significantly. Some plants report around 30% less material ending up in landfills after implementing such systems throughout their operations. Plus there's the added benefit for companies looking to improve their green credentials. Many manufacturers find that customers respond positively to their sustainability efforts, especially among younger demographics who care deeply about environmental impact.

Biodegradable Resin Processing Methods

Looking at how biodegradable resins get processed through blown film machines shows some pretty interesting developments in making sustainable films. The techniques have been specifically designed to work with these delicate biodegradable materials while still producing good quality films that actually function properly. There's huge potential in this market right now because people care more about the environment than ever before, plus governments keep pushing regulations aimed at cutting down plastic waste. Market analysts predict significant growth coming soon as companies across different sectors start switching over to greener packaging options. For manufacturers, this trend represents both an environmental win and a business opportunity as consumers increasingly prefer products wrapped in eco-friendly materials instead of traditional plastics.

Inline Printing Compatibility

Inline printing tech has really boosted how efficient blown film production becomes these days, letting everything happen right there on the production floor instead of moving things around. When manufacturers use flexo presses for inline work, they cut down on several separate steps in the process. The result? Faster turnaround times and better looking prints directly onto the films themselves. What makes this so valuable is twofold actually – operations run smoother overall, plus the finished packages just look nicer which helps products stand out on store shelves. Take some real world cases we've seen lately. Companies adopting this approach report noticeable gains in their bottom line from both time saved during manufacturing and improved brand recognition thanks to those sharper printed designs.

Surface Treatment for Enhanced Adhesion

Getting the right surface treatment on plastic films makes all the difference when it comes to how well prints stick and coatings adhere properly. Methods such as corona treatment really boost the surface energy levels, which means inks just grab onto the material better without peeling off later. For manufacturers working within strict industry specs, this kind of preparation isn't optional but absolutely necessary. Think about packaging materials that need to withstand rough handling while still looking sharp on store shelves. The market data shows pretty clearly that when companies get their surface treatments right from the start, they end up with fewer rejects and happier customers overall. Most experienced plant managers will tell anyone willing to listen that investing time upfront in these treatments pays dividends down the line through reduced waste and higher customer satisfaction rates.

Automated Winding and Slitting Integration

The introduction of automation into winding and slitting operations has really changed how efficient blown film manufacturing can be. Modern automated systems handle films after they come out of the extruder, making sure each cut is accurate and every roll is properly formed while wasting far less material than traditional methods. For manufacturers, this means getting more product off the line without compromising on quality standards. Industry reports point to clear gains in productivity when plants adopt these technologies, including quicker production cycles and lower expenses across the board. Looking ahead, as film blowing equipment keeps advancing, those who integrate automated winding and slitting solutions tend to stay ahead of competitors simply because their production lines run smoother and produce better results consistently.

Table of Contents

- Blown Film Extruder Systems

- Die Designs for Precision Thickness

- Advanced Cooling and Haul-Off Mechanisms

- Tailored Configurations for Packaging Demands

- Agricultural Film Production Adaptations

- High-Strength Construction Membrane Solutions

- IoT-Enabled Process Control Systems

- Multi-Layer Coextrusion Capabilities

- Energy-Efficient Drive Technologies

- Recycled Material Compatibility Features

- Closed-Loop Plastic Recycling Systems

- Biodegradable Resin Processing Methods

- Inline Printing Compatibility

- Surface Treatment for Enhanced Adhesion

- Automated Winding and Slitting Integration