Why Compact Film Blowing Machines Are Essential for Space-Constrained Facilities

Growing demand for space-efficient film blowing machine solutions in urban and high-rent industrial areas

Industrial rents in big cities have gone up around 18% each year since 2021, which has led about three quarters of city based manufacturers to switch to smaller production setups. A recent look at industrial automation data shows that these compact film blowing machines take up 30 to 40 percent less floor space than older models, all while still producing between 85 and 120 kg per hour. For places like Hong Kong where factory spaces often measure under 4,000 square feet, this kind of space saving makes a huge difference. Factory owners there literally fight over every square meter because real estate costs eat into profits so quickly. The math just doesn't work otherwise when rent keeps climbing faster than most businesses can grow.

How spatial limitations are driving innovation in blown film extrusion design

Limited space has really pushed manufacturers to get creative with things like foldable towers and radial cooling setups. Take a plant in Bangkok for example they saw their output jump around 22 percent when they switched to vertical extruders. The whole production line now fits into just 40 percent of what used to be needed on the factory floor. What's interesting is these new technologies actually work pretty well even when there's barely three meters between the floor and ceiling. Back in the day, anyone trying to run blown film operations would have laughed at the idea of making this happen in such tight spaces.

Balancing output capacity with reduced footprint: Can compact machines compete?

The latest compact versions actually produce about 98% of what traditional systems manage, all while taking up only 65% of the floor space needed before. This goes against what many people think about equipment size directly affecting performance capabilities. Thickness remains consistently controlled at around plus or minus 1.5 microns thanks to automated gauge systems, matching what bigger machines accomplish despite their higher power demands. And according to research from the Plastics Engineering Journal last year, these smaller setups cut energy bills by somewhere between 18 to 25 percent. For companies where workspace matters but production volume can't drop, compact film blowing machines are becoming increasingly attractive options without compromising on product quality standards.

Key Design Innovations in Compact Film Blowing Machine Architecture

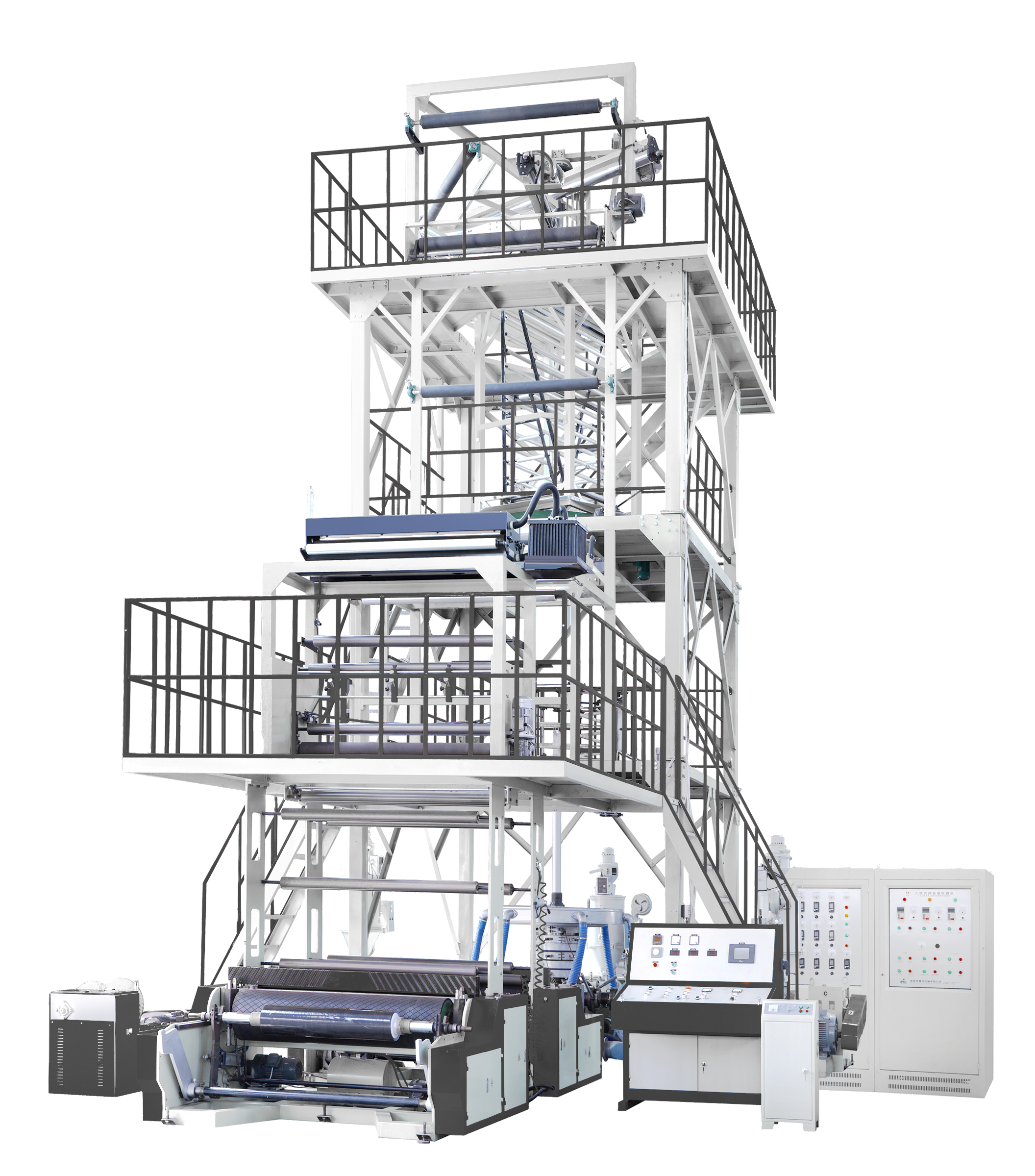

Vertical Tower Optimization and Modular Construction for Tight Factory Layouts

The latest compact film blowing machines come equipped with vertical extrusion towers stacked on top of each other, cutting down required floor space by around 40 to 55 percent compared to traditional horizontal setups. With modular designs, factories can put together parts such as screw extruders and cooling rings in various arrangements, making it possible to customize equipment even when workshop space is limited. A case study from one manufacturer shows their adaptable system kept about 90% of normal production going through several layout adjustments in cramped industrial spaces. This proves that saving space doesn't necessarily mean sacrificing reliable operations either.

Case Study: 35% Footprint Reduction Using Re-Engineered Tower Design in a Southeast Asian Packaging Facility

Looking at a flexible packaging operation in Malaysia back in 2023 showed some interesting results when they installed smaller machines with helical gear reducers and built-in motor drives. These upgrades actually cut down the length of each production line by nearly 3 meters. The plant also went for a three level cooling setup vertically stacked along with fold away platforms for maintenance work. This allowed them to fit 6 more production lines into the same space they had before – going from 12 to 18 lines per thousand square meters which means getting 35% better use out of their floor space. What's even better is that workers managed to keep producing around 220 kilograms per hour but used 18% less energy overall because there wasn't as much need for constant air movement throughout the facility anymore.

Die Head and Air Ring Configuration Advancements Enabling Stable Bubble Control in Confined Systems

The latest dual-lip air ring designs featuring carefully engineered airflow channels are making it possible to create stable bubbles even when working under ceilings less than six meters high. Tests conducted by third-party labs indicate that these new die head shapes keep thickness differences within about 2.5 percent range in tight spaces, which actually matches what traditional systems can achieve. When it comes to managing width stability in narrow production areas, real time monitoring of melt pressure combined with automatic mandrel adjustments seems to stop roughly 89 out of every 100 potential width issues. These findings come from recent research published in extrusion process journals back in 2024.

Maintaining Performance: Output, Quality, and Efficiency in Compact Units

Material Throughput Capabilities of Compact Film Blowing Machines vs. Traditional Systems

Despite their smaller size, modern compact film blowing machines achieve throughput levels comparable to traditional systems. A 2023 study found that leading 45mm compact extruders can process up to 320 kg/hr of LLDPE–reaching 85% of conventional line capacity while using 40% less floor space. This performance stems from three core innovations:

- High-torque planetary gearboxes minimizing power loss

- Multi-layer coextrusion dies enabling 30% faster resin melting

- Automated rheology control ensuring consistent melt flow

The table below compares throughput across common materials:

| Material | Compact Machine (kg/hr) | Traditional Line (kg/hr) | Space Saved |

|---|---|---|---|

| LDPE | 280–340 | 320–400 | 38% |

| HDPE | 240–300 | 280–360 | 42% |

| PP | 260–320 | 300–380 | 35% |

Performance Benchmarks: kg/hr Output and Gauge Consistency Across Leading Compact Models

The best compact units on the market today can maintain around 5% gauge consistency even when running at output levels as high as 480 kg per hour, which is pretty impressive considering they're competing with much larger systems. Take for instance this packaging facility in Vietnam that switched to compact equipment last year. They saw their yield jump from about 86% to nearly 98%, according to the Plastics Engineering Journal from 2023. That's a solid 12 percentage point gain right there. What these numbers really show is that going compact doesn't mean sacrificing performance anymore. Speed remains competitive and product quality stays intact, making these smaller machines serious contenders in industrial settings where space matters most.

Energy Efficiency Gains: How Compact Extrusion Lines Achieve 22% Lower Consumption

Advanced thermal management reduces energy use by 22% in compact film blowing machines compared to standard lines. Key contributors include:

- 12% shorter heating zones with ceramic-insulated barrels

- Variable-frequency drives cutting idle power draw by 34%

- Integrated IoT-enabled energy monitoring systems optimizing real-time consumption

Overcoming the Cooling Zone Challenge: Ensuring Uniform Film Quality in Reduced-Height Setups

To address limited vertical space, compact machines employ dual-path air cooling technology, accelerating heat dissipation by 27%. Manufacturers achieve 0.02mm thickness uniformity–equal to traditional towers–through:

- Oscillating air rings with 15% wider dispersion patterns

- Multi-stage chill rolls compensating for shorter bubble runs

- Real-time IR sensors dynamically adjusting cooling rates during operation

Smart Integration and Operational Control in Confined Industrial Environments

Adapting the Blown Film Extrusion Process for Low-Clearance Facilities

Compact machines often go with vertical tower designs and modular parts so they can work well in spaces where there's not much headroom. Looking at actual factory implementations, companies typically save around 30 to 40 percent on floor space by switching from traditional horizontal arrangements to these stacked extrusion towers. This makes it possible to install equipment even in older buildings with ceiling heights down to about 15 feet. The newer servo driven haul off systems basically cut out all that sideways spreading out while still maintaining almost perfect line efficiency rates at about 98% according to recent data from the Plastics Processing Alliance back in 2023.

Role of Automation and IoT-Enabled Controls

PLCs and machine learning algorithms automate critical functions like bubble stabilization and tension control–especially valuable in confined spaces where manual access is limited. Industry reports indicate that IoT-connected units reduce setup times by 65% through predictive die head calibration, while remote diagnostics cut maintenance-related floor space needs by 42%.

Future-Ready Scalability and Integration

Top manufacturers now produce compact modular systems that come with standard interfaces, so factories can expand their capacity bit by bit without needing to completely redesign their floor plans. The new hybrid cooling approach mixes vertical air movement with smart temperature adjustments powered by machine learning algorithms. This works really well alongside current climate control systems already in place at most facilities. Even when space is tight, these scalable designs keep thickness variations under 1.5% from batch to batch. That kind of precision matches what traditional manufacturing systems have been able to achieve for years, but with added flexibility that makes them much better suited for today's changing production needs.

FAQ

Why are compact film blowing machines beneficial for urban and high-rent areas?

Due to rising industrial rents in cities, compact film blowing machines are essential as they occupy 30 to 40 percent less space than traditional models, which is crucial in space-constrained urban facilities.

How do compact film blowing machines perform compared to traditional systems?

Compact versions produce approximately 98% of what traditional systems do, while taking up only 65% of the footprint, all while maintaining high product quality and efficiency.

What design innovations have been introduced in compact film blowing machines?

Innovations include vertical extrusion towers, modular construction, advanced die head and air ring configurations, and more efficient cooling systems to optimize space and performance.

How do compact film blowing machines achieve energy efficiency?

They utilize advanced thermal management, shorter heating zones, variable-frequency drives, and IoT-enabled systems to reduce energy consumption by up to 22% compared to standard lines.

Table of Contents

- Why Compact Film Blowing Machines Are Essential for Space-Constrained Facilities

- Key Design Innovations in Compact Film Blowing Machine Architecture

-

Maintaining Performance: Output, Quality, and Efficiency in Compact Units

- Material Throughput Capabilities of Compact Film Blowing Machines vs. Traditional Systems

- Performance Benchmarks: kg/hr Output and Gauge Consistency Across Leading Compact Models

- Energy Efficiency Gains: How Compact Extrusion Lines Achieve 22% Lower Consumption

- Overcoming the Cooling Zone Challenge: Ensuring Uniform Film Quality in Reduced-Height Setups

- Smart Integration and Operational Control in Confined Industrial Environments

-

FAQ

- Why are compact film blowing machines beneficial for urban and high-rent areas?

- How do compact film blowing machines perform compared to traditional systems?

- What design innovations have been introduced in compact film blowing machines?

- How do compact film blowing machines achieve energy efficiency?