High-Barrier Plastic Packaging Fundamentals

Why High-Barrier Materials Matter in Modern Packaging

High barrier materials are essential for keeping products fresh and extending their shelf life, particularly important for things like food items and medicines. These materials work by blocking out oxygen, moisture, and light which helps protect delicate components from breaking down over time. Maintaining product quality isn't only good for customer happiness but also necessary to comply with various regulations across different markets. According to recent research from Smithers Pira, there's expected to be significant expansion in the high barrier packaging sector as companies increasingly seek out eco friendly alternatives. What this shows is how the industry is moving toward materials that deliver practical advantages alongside greener credentials. Looking ahead, continued investment in these barrier technologies will likely define where packaging goes next, balancing product integrity with lower environmental impact across manufacturing processes.

Key Applications of Barrier Plastic Bags (Food/Pharma/Chemical)

Plastic barrier bags play a critical role across many different industries because they offer protection where it matters most. Take the food business for instance - these special bags keep fresh produce safe from dangerous bacteria such as botulism, which nobody wants finding its way into their grocery store purchases. Food companies rely on this protection not just for health reasons but also to protect their brand image when something goes wrong. When it comes to medicine, proper storage makes all the difference. Medications need to stay free from dirt and dampness so patients get what they paid for without risking side effects from spoiled products. Chemical manufacturers face similar challenges too. Without good barrier properties, there's always the risk of spills that could lead to fines or worse environmental damage. Looking at how widely used these bags are shows why they've become such an essential part of packaging today. They help maintain standards while keeping costs down through better long term performance compared to alternatives.

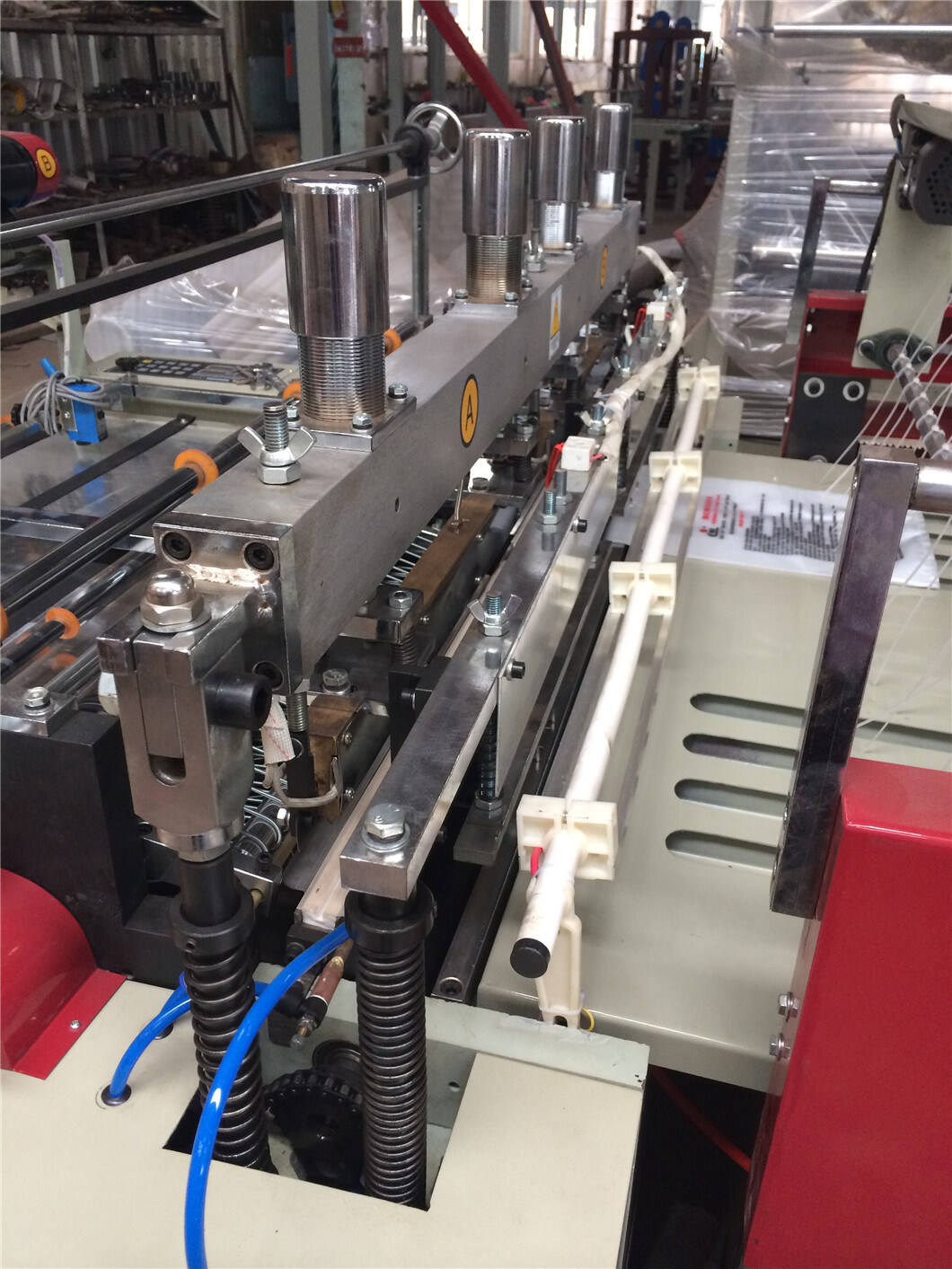

Core Components of Plastic Bag Making Machines

Blown Film Extrusion Systems for Barrier Layers

Blown film extrusion systems are really important when it comes to making plastic bags that have those special high barrier layers. They give the bags both flexibility and durability that just cant be matched by other methods. What makes these systems so valuable is their ability to create multiple layers at once, which boosts how well they block out things like moisture and oxygen. And this means better protection for whatever gets packaged inside. The process itself has some pretty cool advantages too. It actually improves bag quality while using about 30 percent less material than traditional approaches. That translates into real money savings on the production line. We see these systems all over the place across different sectors, particularly where packaging standards need to be rock solid. Think about food products that must stay fresh longer or medicines that require absolute protection from contamination. For these industries, getting the packaging right isn't just nice to have it's absolutely critical for keeping customers safe and satisfied.

Multi-Layer Sealing and Lamination Technologies

Getting multi-layer sealing and lamination right matters a lot for keeping packaging intact over time. These tech innovations help make packaging that stops moisture and oxygen from getting inside, something that really counts in sectors where product quality is everything, like food processing or medicine manufacturing. When we talk about lamination specifically, it basically creates an extra shield against outside elements, making products last longer on shelves. Industry reports suggest that when companies implement these better sealing methods along with proper lamination, they often see around 40% improvement in how strong the packaging holds up. This kind of performance boost meets those tough standards regulators keep setting higher all the time. As manufacturers keep pushing forward with new materials and techniques, what becomes clear is that these packaging advancements aren't just nice to have anymore but essential for staying competitive in today's market.

Integrating Recycling Technology in Production Lines

Post-Consumer Recycled Material Processing

Bringing post-consumer recycled materials into our production processes plays a major role in cutting down environmental damage and helping us move toward more sustainable operations. While working with these recycled materials through various technologies does come with its own set of problems, there are definitely worthwhile advantages too. We need special machinery to keep the end products reliable and high quality, so they perform just as well as items made from new materials. According to research published by the EPA, increasing the amount of PCR used during manufacturing can actually cut carbon emissions by around 30 percent or more. That kind of reduction represents a real breakthrough for companies trying to green up their manufacturing approaches without sacrificing product quality.

Closed-Loop Systems for Sustainable Manufacturing

Closed loop systems have become a smart move for manufacturers wanting to boost sustainability efforts. Basically what happens is production waste gets reused instead of ending up in landfills, which cuts down on environmental damage and actually makes operations run smoother too. When companies track where materials go during production, then recycle them back into the process, everyone involved knows exactly what's happening throughout the whole chain. A study done by packaging experts showed something interesting - businesses implementing these kinds of systems tend to save between 15% and 20% on operations costs. That kind of financial benefit combined with greener practices explains why more factories are starting to adopt this approach despite initial setup expenses.

Automation Trends in Bag Manufacturing

Smart Sensors for Thickness Control

Smart sensors are changing how bags get made, especially when it comes to monitoring film thickness during production. These little devices help keep the barrier properties just right by making sure the plastic stays consistently thick throughout, which cuts down on wasted materials. We're seeing an interesting trend toward automation in this sector, with companies getting much better control over their manufacturing processes. Some reports suggest production could jump around 25% once these sensors become standard equipment across factories. When manufacturers actually put these technologies into practice, they notice fewer inconsistencies in film thickness. This means less scrap material going to waste and ultimately better quality products hitting store shelves. For businesses trying to stay ahead in a tough marketplace, this kind of improvement makes all the difference.

AI-Driven Quality Assurance Systems

Quality assurance systems powered by artificial intelligence are transforming how defects get spotted and processes optimized in bag manufacturing. These smart systems look at mountains of production data as it happens, letting factory managers catch problems early before they turn into bigger headaches. Industry reports suggest AI adoption could cut down on defects by around 30 percent, which means bags that actually hold up under stress tests. For manufacturers looking to tighten their quality checks while keeping production moving smoothly, these systems offer real value. Fewer faulty products make it out the door, saving money on returns and boosting brand reputation. Investing in this tech isn't just about staying ahead of competitors anymore it's becoming essential for companies wanting to meet rising consumer expectations for consistent quality.

Choosing Machinery for Biodegradable Materials

Temperature Control for PLA/PHA Processing

Getting the temperature right matters a lot when working with biodegradable stuff like PLA and PHA during melting and forming operations. If the temps aren't just right, the material properties start breaking down and the finished product won't work properly. We've seen time and again in production runs that keeping temperatures stable makes all the difference in film quality. The films last longer and perform better overall. For manufacturers making biodegradable bags, getting these temperature parameters spot on is absolutely necessary. These eco-friendly materials need pretty specific conditions to make sure the packaging holds up under normal usage without falling apart prematurely.

Modified Extruders for Compostable Films

Changing standard extruders plays a key role when manufacturers want to work with compostable films since these materials have very different properties compared to traditional plastics. The modifications improve how well the machines mix and melt ingredients, which matters a lot when dealing with the unconventional substances found in biodegradable films. Industry data actually shows why companies need these upgraded extruders for producing biodegradable packaging. Some reports point to productivity gains of around 20% when using modified equipment. Companies that invest in these specialized machines stay ahead of competitors without compromising on green standards. What's more, businesses get to experiment with new formulas and create better performing biodegradable films at the same time they cut down waste. This helps move the whole packaging sector toward more environmentally friendly practices over time.