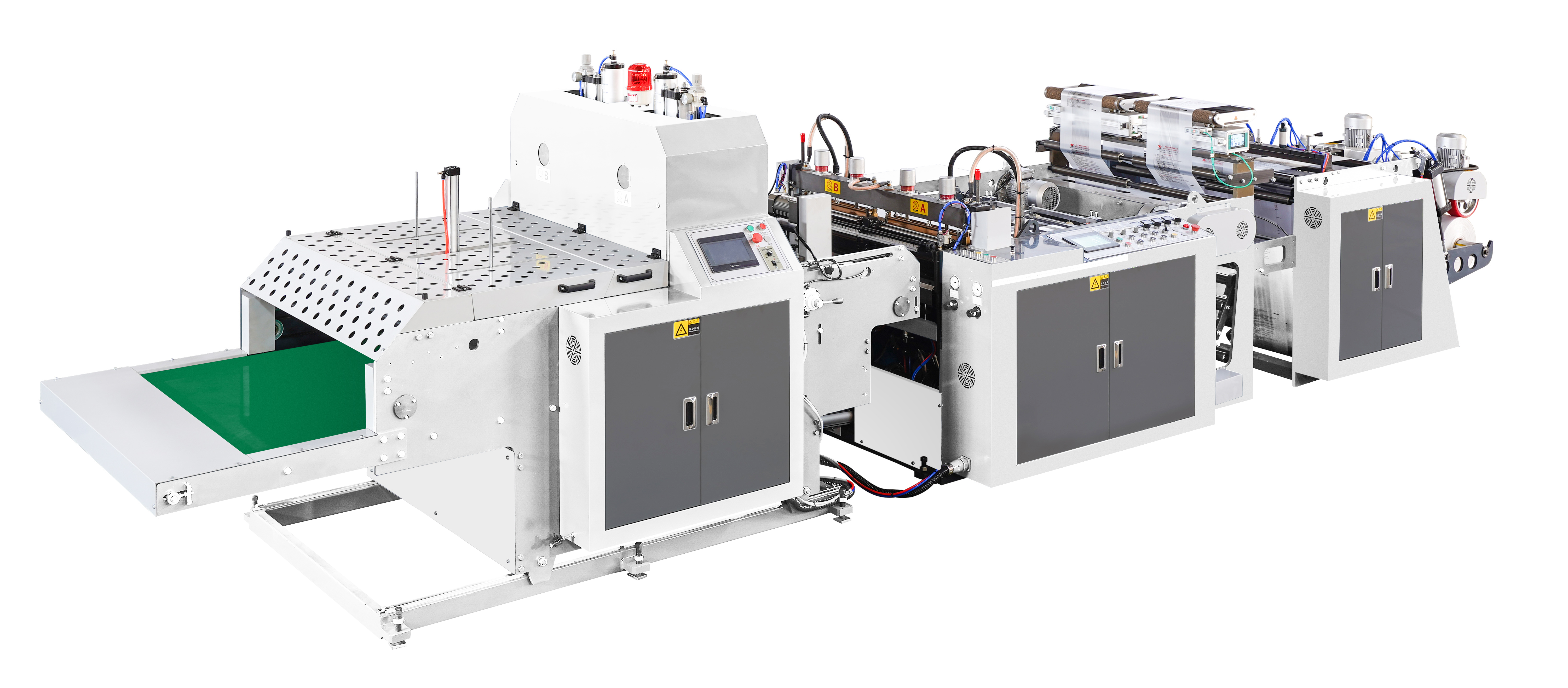

Multi-Functional Bag Machines: Core Components and Capabilities

Integrated Flexographic Printing Systems

When flexographic printing gets built into bag making equipment, it really boosts how fast things get done because bags can be made and printed at the same time. These systems run pretty quick and put nice looking designs on all sorts of stuff from paper to different plastics. The real advantage comes when companies need to crank out large quantities without missing a beat. Most plants find they can turn work around much faster than before, which means staying competitive in today's market. Looking at actual shop floor data, most manufacturers report about 30% better throughput with these combined systems versus using separate printing units. Time saved translates directly into money saved, something every plant manager appreciates during tight budget periods.

Blown Film Extruder Compatibility

Blown film extruders are really important when it comes to creating quality film needed for bags, which ultimately affects how long those bags last and if they work properly for their intended purpose. Bag machines that do multiple functions have been built specifically to work well with these extruders, giving factory owners the kind of flexibility they need day to day. When everything works together smoothly, production runs become much more efficient. Factories can cut down on expenses while getting products out faster too. Industry reports consistently show that this kind of setup saves money and boosts output capacity across the board, so no wonder big manufacturers tend to go with this approach when scaling up their operations.

Automated Handle and Bottom Sealing

Automatic sealing of handles and bottoms plays a big role in making better quality bags faster during production. The tech behind these systems really helps out because it makes bags last longer and look nicer too something customers notice right away and companies care deeply about for their brand image. When manufacturers use advanced sealing methods, they get much more consistent results across all products, so every single bag maintains good structure without weak spots. Factories switching to these automated setups often see real improvements on their bottom line lower wages spent on manual labor plus way more units coming off the assembly line each day. Most bag makers now view going automatic not just as cost cutting but actually part of staying competitive in markets where consumers expect top notch packaging solutions.

Advancements in Printing Technology Integration

High-Speed Flexo Press Operations

The introduction of high speed flexo presses has really changed how long it takes to produce bags. These modern machines can crank out massive quantities without stopping much, which cuts down on wasted time during production runs. The tech behind flexographic printing has gotten better too, so the printed designs on bags look crisper and last longer through handling and shipping. Industry experts writing in trade magazines point out that manufacturers now run their presses faster than ever before without sacrificing print quality, something that was hard to achieve just a few years ago. What we're seeing here isn't just about making things quicker; these improvements actually result in better looking products that customers notice right away when they pick up a package from store shelves.

Inline vs. Offline Printing Configurations

The decision between inline versus offline printing setups matters a lot when trying to get the most out of available space and keep production moving smoothly. With inline systems, printing gets built right into the bag making itself, which cuts down on wasted floor space and makes everything run faster. The downside? These systems tend to cost more upfront. On the flip side, going with offline printing gives manufacturers more room to play around with different designs and specifications. But there's a catch too – these setups usually need extra space and equipment lying around. Looking at actual factory numbers tells us something interesting: inline tends to boost productivity metrics significantly, whereas offline options let companies experiment with special prints without messing up regular production schedules. At the end of the day, what works best really comes down to what each plant values most – speed and compactness or flexibility and customization potential.

Precision Color Matching Techniques

Getting colors just right matters a lot for brands making bags and keeping customers happy. These days most factories use fancy color sensors along with special software to keep colors looking the same from one production run to another. This helps protect what makes a brand recognizable and builds trust with shoppers who expect consistency. Market surveys show people really care about accurate colors when they buy printed items. When manufacturers invest in good color matching tech, they end up creating bags that look great batch after batch. The products stand out more on store shelves, which means better sales. Plus customers start to associate those consistent, bright colors with quality craftsmanship, so they come back for more purchases over time.

Seamless Film-to-Bag Manufacturing Lines

Putting film-to-bag manufacturing together is changing how fast things get made on the factory floor. When different parts of production line up properly, factories run smoother with less waiting around between steps. Downtime drops quite a bit and workers get more done throughout the day. The whole process just flows better when raw materials move directly into the next stage without stopping. Some numbers show these connected systems save real time money for companies. Most bag makers are seeing this now as they try to keep up with customers who want their orders quicker while still keeping costs down across the board.

When manufacturing lines work together as one cohesive system, the whole process flows much better from start to finish. Bottlenecks that used to cause headaches just disappear, and nobody has to wait around for parts or materials anymore. Less downtime means production keeps moving forward without those frustrating stoppages that waste time and money. Factories running integrated systems get way more out of their equipment and workforce because everything runs smoothly day after day. The numbers back this up too many plants report productivity jumps once they've fully integrated their operations, sometimes seeing output increases that make all the investment worthwhile.

Multi-Layer Material Handling Efficiency

Using multi-layer materials when making bags brings real advantages for how long they last and what they can do, which makes products perform better overall. Modern machinery has gotten pretty good at working with these complicated materials through multiple processes at once. When manufacturers get the handling right, they can really take advantage of what multi-layer materials offer to create bags that stand up to wear and tear while maintaining quality over time. This matters a lot because consumers want stronger, more versatile bags these days than ever before, especially as we see increased focus on sustainability and reducing waste.

When it comes to running things day to day, better tech for working with those multi layer materials really cuts down on what we spend to make products. Industry numbers show these improvements actually bring down total costs quite a bit, so factory crews can keep making stuff without breaking the bank. These kinds of savings matter a lot when trying to price bags competitively while still turning a profit. Bag makers need every edge they can get right now since everyone wants cheaper options but still expects quality workmanship. Looking ahead, companies that focus on getting their material handling processes just right will probably stay ahead of the curve as customer needs change and new competitors enter the market.

Waste Reduction Through Automated Controls

Automated controls in bag making really cut down on waste while making the whole process way more efficient. These systems watch what's happening on the factory floor and tweak settings as needed, so materials get used properly instead of ending up as scrap. When companies manage to reduce waste, they save money and hit those green targets too. Some plants report saving thousands annually just from better waste management. For manufacturers looking to stay competitive, effective waste control isn't just good for the bottom line it's becoming almost essential for keeping customers happy who care about sustainability these days.

A bunch of manufacturing research papers along with sustainability reports back up how much of a difference automated controls make when it comes to cutting down waste. Take a look at some recent findings from the plastic packaging sector for example. These tech upgrades often cut waste by around 30% or so according to industry insiders. What makes this stuff work so well is that companies can slash waste without slowing down production speeds. This fits right into what most manufacturers are trying to accomplish nowadays balancing green goals with bottom line concerns. As consumers get pickier about environmental impacts, factories that invest in smart automation systems find themselves ahead of the game both ecologically and financially speaking.

Industry Applications and Operational Benefits

Retail-Grade Custom Printed Packaging

Custom printed packaging has become really important for retailers wanting their products to stand out. Brands get better visibility when they use custom packaging, which helps grab shoppers attention and keeps customers coming back. Retailers want unique packaging because it makes their products look different from all the others on store shelves, creating something customers remember. That's where those multi functional bag machines come into play. These machines let stores change print designs, colors, and even materials without much hassle, so businesses can keep their packaging fresh and adapt quickly to what's selling well. Market research shows that companies spending money on custom packaging tend to boost sales and engage customers more effectively than those sticking with standard options. While not every business will see dramatic results overnight, most find that investing in good looking, tailored packaging pays off in the long run as consumers gravitate toward products that look special and worth buying.

Food-Safe Bag Production Standards

Getting food safety right matters a lot when making bags, especially those used for food packaging purposes. When manufacturers stick to strict safety guidelines, they make sure the stuff going into production won't harm anyone who touches or eats what's inside. These days, most modern bag making equipment comes equipped with food safe materials, inks that don't leach chemicals, and overall cleaner design features built right into how bags get made. Putting all these safety aspects together means the machines meet what various international food safety groups require for proper certification. Looking at numbers provided by major food safety watchdogs shows pretty clearly that following these rules cuts down on contamination risks. That protects people's health obviously, but it also builds customer confidence in brands that take food safety seriously.

Large-Scale Industrial Workflow Solutions

Big industrial operations need solid workflow systems that can manage massive production volumes without breaking down. Multi-functional bagging machines tackle this problem head on by offering scalable production power along with cutting edge tech that keeps everything running smoothly. The real benefit comes from improved workflow efficiency which lets companies adjust rapidly when production needs change but still keep output at high levels. Industry reports consistently show that investing in this kind of technology boosts competitiveness and productivity across the board. Manufacturers who upgrade their equipment typically see lower costs per unit produced and gain ground in competitive markets. Looking at the bigger picture, staying ahead means embracing new innovations and being able to pivot when needed in today's fast moving manufacturing landscape.