Why Paper Bag Machines Are Essential for Food Packaging

Growing Demand for Sustainable Food Packaging Solutions

Global sustainability initiatives are really pushing companies to adopt greener packaging solutions, particularly in food production where packaging waste has become such a big issue. Market research from Smithers Pira suggests the sustainable packaging sector could hit around 500 billion dollars by 2027, which shows just how much things have changed when it comes to what consumers want from their packaging. Paper bag manufacturing equipment plays a key role here since these machines let producers crank out lots of biodegradable bags and containers quickly. For many businesses trying to stay ahead of regulations and customer expectations, investing in paper bag machines makes sense both practically and financially. They help meet those tough environmental standards while also giving companies something tangible they can market as part of their green credentials in an increasingly eco-aware marketplace.

Regulatory Shifts Away from Single-Use Plastics

Around the world, government bodies are putting in place rules to limit single-use plastic products, which means businesses have to find other ways to package their goods. Take the European Union as an example they've rolled out several directives targeting plastic waste reduction across member states. With all these new laws coming into effect, paper bag manufacturing equipment has become essential for companies trying to keep up with regulatory requirements. The machines themselves provide a practical solution for switching over to eco-friendly packaging options. Not only do they help maintain compliance with environmental standards, but they also allow businesses to market themselves as part of the green movement without sacrificing product protection during shipping and handling.

Consumer Preference for Eco-Friendly Materials

More people these days seem to be looking for green packaging options. Studies suggest around 70% would actually spend extra cash on items wrapped or boxed in eco friendly ways. We're seeing something bigger happening here too - folks across society are starting to care more about what they buy and how it affects the planet. For businesses, this means there's real potential to win customer hearts by going green. When companies bring in those paper bag making machines for their factories, they're not just meeting market demands but also boosting their reputation as caring brands. Plus, switching to paper bags helps protect our environment in practical ways.

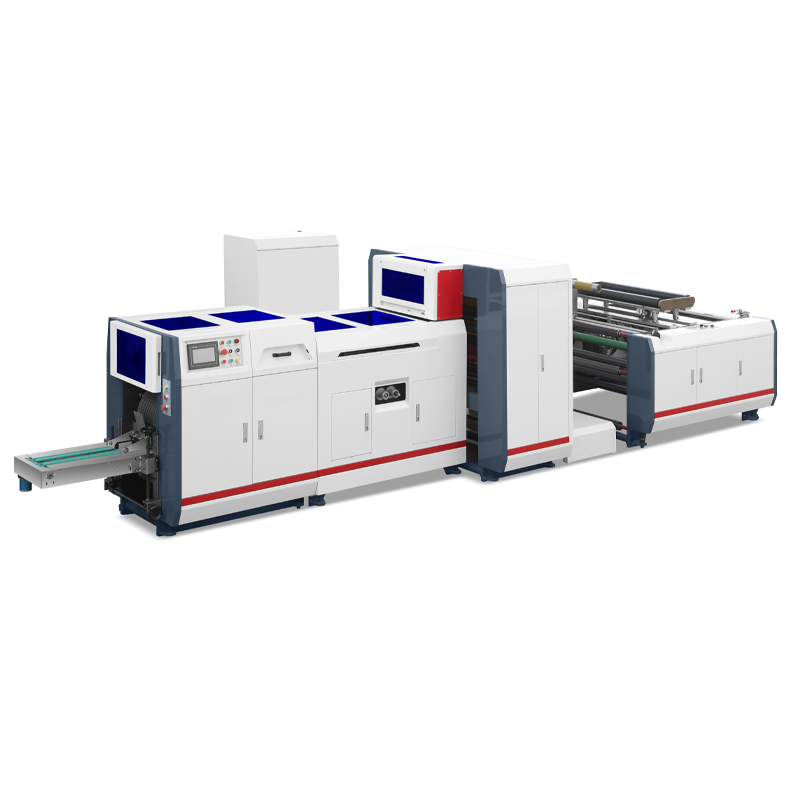

Key Features of High-Quality Paper Bag Making Machines

Automated Production for Consistency and Speed

Paper bag making machines of good quality really shine when it comes to automated production that keeps things consistent and fast moving. The truth is, automation makes all the difference in speeding things up while cutting down on those pesky human mistakes, something that matters a lot in big scale food packaging operations. Most modern machines come equipped with pretty sophisticated automation tech, some capable of cranking out around 200 bags every single minute. That kind of throughput means companies can actually keep up with the growing demand for environmentally friendly packaging options without breaking a sweat. Looking at the bigger picture, adding automation into manufacturing isn't just about getting more done faster it's becoming standard practice across the industry as everyone scrambles to improve both efficiency and accuracy in their packaging processes.

Food-Grade Material Compatibility (Kraft & Recycled Paper)

High quality paper bag machines work well with food grade materials like Kraft and recycled paper options. The equipment handles different kinds of paper stock while meeting those important health and safety rules that food processors have to follow. Kraft stands out because it's strong and won't let moisture through, which makes sense when packaging things that go bad quickly. When manufacturers choose Kraft or recycled papers, they check off both boxes regulatory-wise and green initiatives too. Most customers these days want something environmentally friendly but still want good quality bags, so this approach hits all the right notes without cutting corners on performance.

Precision in Bag Dimensions and Handle Integration

Getting the right measurements and properly attaching handles are signs of good quality in paper bag manufacturing equipment. When bags come out consistently sized, they fit better with products and look nicer on store shelves. Plus, precise dimensions mean less wasted material during production. The size matters because it affects how customers see the product inside and whether it matches the brand image. Handles matter too. They make it easier to carry items without damaging them, which keeps the overall appearance intact. Bags with well integrated handles work across different markets from grocery stores to retail outlets. People appreciate not having to struggle with awkward packaging when shopping, so proper handle placement actually boosts customer happiness and repeat business.

Benefits of Specialized Machines for Food Paper Bags

Enhanced Durability for Heavy or Moist Products

Paper bag making machines designed for specific purposes help create bags strong enough to handle everything from fresh produce to frozen goods without falling apart. The engineering behind these machines strengthens regular paper so it holds up during shipping and while sitting on store shelves. When manufacturers improve how the paper layers stick together, they get bags that won't tear open or leak contents, which keeps food safe until customers actually buy it. For grocery stores and restaurants that need reliable packaging solutions, this matters a lot. Think about bread deliveries or milk shipments where even small failures can lead to big losses. That's why many food businesses invest in good quality paper bag production equipment despite the upfront costs.

Compliance with Food Safety Standards

Meeting food safety regulations matters a lot when it comes to machines making paper bags for food products. The equipment has to handle materials approved by the FDA or similar regulatory bodies so nothing gets into the food packaging that shouldn't be there. Keeping things clean isn't just good for people eating whatever goes inside those bags it also keeps manufacturers out of trouble legally speaking. When a factory gets certified by recognized organizations, it shows they take safety seriously. For businesses trying to convince customers they care about quality, these certifications become pretty important selling points in discussions with buyers who want assurance about what ends up in their shopping carts.

Custom Printing for Branding and Labeling

Adding custom printing features to paper bag machines gives businesses something really useful when it comes to getting their name out there and talking to customers. With these machines, companies can slap their logos, run promotions, or put important details right on the bags themselves. The best part? It does two things at once. When people see familiar branding on packaging, they tend to remember the brand better and might even develop some loyalty over time. Plus, having all the necessary product info printed clearly helps avoid regulatory headaches down the road. For food businesses fighting tough competition, this matters a lot. Consumers in grocery stores often make split second decisions based on what they see, so clear branding combined with full disclosure about ingredients and nutrition becomes a real selling point.

Choosing the Right Machine for Food-Grade Paper Bags

Assessing Production Volume and Automation Needs

Picking the right paper bag making equipment for food items starts with figuring out how much stuff needs to be produced each day. Some companies have busy seasons where they need double or triple their normal output, while others operate at steady levels throughout the year. Knowing these patterns helps pick machinery that won't sit idle during slow times but still handles rush periods without breaking down. Automation levels matter too. Fully automatic systems cut down on manual work hours, which saves money over time. They also speed things up across the whole production line. For instance, semi-automatic models might handle basic tasks while staff focuses on quality checks. Finding this sweet spot between what the factory can produce versus how many workers are needed makes all the difference. Smart manufacturers know that getting this balance right means turning out more bags per hour while keeping overhead expenses under control, something that gives them an advantage when competing against other producers in the marketplace.

Importance of Modular Design for Flexibility

Manufacturers who go for modular machine setups are actually making smart business decisions when it comes to staying flexible. Take paper bag making equipment for instance these days many come with interchangeable parts that let factories expand their capacity or tweak what they produce without spending a fortune on brand new machines. The real benefit shows up in markets where demand goes up and down all the time, think about those busy holiday seasons when food packaging companies suddenly need double their usual output. With modular systems in place, businesses can switch gears fast enough to catch those market shifts before they miss out on sales opportunities. Most plant managers I've talked to say this kind of setup keeps their operations running smoothly even when customer preferences change overnight.

Energy Efficiency and Maintenance Requirements

Cutting down on energy use remains high on the list for companies trying to save money and shrink their carbon footprint. When it comes to paper bag production, going with machines designed for better energy performance makes good business sense. These systems help hit those green targets without breaking the bank on running costs. But there's another angle worth considering too. Knowing how these machines actually need to be maintained matters just as much as buying them in the first place. Nobody wants production grinding to a halt because something broke down unexpectedly. Weekly inspections, oil changes every few months, replacing worn parts before they fail completely – all these routine steps keep operations rolling smoothly. For manufacturers who really care about both their bottom line and planet, finding that sweet spot between efficient machines and reasonable upkeep demands becomes absolutely essential.

Choosing the right machine for food-grade paper bags involves careful consideration of production needs, flexibility, energy efficiency, and maintenance. By aligning these factors with strategic business goals, manufacturers can enhance their operational efficiency and remain competitive in the dynamic paper bag industry.

Future Trends in Paper Bag Manufacturing Technology

Integration of AI for Predictive Maintenance

The paper bag manufacturing sector is seeing major changes as companies start using artificial intelligence (AI) systems, especially when it comes to keeping machines running smoothly. With AI technology, plant managers can spot potential breakdowns days ahead of time, which cuts down on those frustrating stoppages that slow everything down. Some industry reports suggest that these smart maintenance practices might slash repair bills by around 30% over time. For factory owners, this means fewer unexpected repairs and better workflow management throughout the day. Most importantly, consistent production runs lead to happier customers getting their orders on schedule without delays caused by equipment problems.

Advancements in Water-Based Coatings and Inks

The latest developments in water based coatings and green inks are changing how good paper bags look and last, all while keeping them environmentally friendly. Companies can now boost the appearance and durability of their packaging without giving up on biodegradability. For businesses wanting to stay green but still stand out on store shelves, these new materials let them print bold colors that won't fade easily. Many retailers have already switched to this approach because consumers increasingly want packages that don't harm the planet. Plus, most countries now require certain environmental standards for packaging materials, so going green isn't just marketing smartness anymore it's becoming business necessity.

Role of Circular Economy Principles in Machine Design

Circular economy thinking is starting to show up in how paper bag machines get designed these days, with many companies looking at sustainability from start to finish in their production process. What does this actually mean? Well, manufacturers are increasingly turning to materials that can be recycled again and again, while also adopting manufacturing techniques that consume less power and create less scrap material. When companies build their equipment with green considerations upfront, they tend to see a noticeable drop in their impact on the environment. The good news doesn't stop there either. These eco-friendly approaches generally work out better financially over time too, which explains why more and more businesses are jumping on board despite initial costs seeming high. For anyone serious about running operations sustainably, incorporating circular economy concepts into machinery design just makes sense both environmentally and economically speaking.