Ручне проти автоматизованого виробництва мішків: ключові аспекти для великопромислового виробництва

Прихований вартість ручного виробництва рулонних мішків

При обчисленні фактичних витрат на виготовлення ручних сумок, потрібно враховувати багато прихованых витрат, а не тільки видимі витрати на матеріали та працю. Ручні способи виробництва часто ставлять високі вимоги до працівників та спеціалізованої освіти, що призводить до дуже високих витрат. Чим довше триває виробництво та існує можливість проблем з контролем якості, тим більше викидів та повторних робіт. Звіт виявив, що автоматизація з часом може зменшити витрати на виробництво на 30% завдяки підвищенню ефективності та зменшенню кількості працівників. Додаткові витрати такі як ці є ключовим фактором, що спонукає багатьох переходжити на автоматизовані рішення для виготовлення сумок, де ефективність та якість покращуються одночасно.

Виклики масштабування в традиційних методах

Традиційні ручні підходи випробовані, але важко масштабувати. Якщо сучасні швидкі ринкові потреби компанія не може ефективно масштабувати, яка вартість пропущеної можливості чи дохід? Компанії, зокрема ті, що використовують ручні методи, мають проблеми з масштабуванням вгору і вниз за потребами, тому вони втрачають ринкову участь. Дослідження показали, що у порівнянні з ручною системою автоматична система верстату може виробляти від 1 до 5 разів більше продукції, без будь-якого зниження якості. Залежність від застарілих розв'язків для великомасштабних операцій часто обмежує можливості, що стає точкою перевірки для інвестицій у автоматизацію для вирішення цих шийних пунктів.

Екологічний вплив непроцесів без автоматизації

Ще один тривожний момент — це екологічні наслідки неавтоматизованих методів виробництва. Ручне виготовлення часто включає незастосовні практики, що мають більший негативний вплив на середовище. Швидке накопичення відходів не тільки ставить під загрозу місткість смітниших поліг, але й суперечить зростаючій потребі у бізнес-практицях, відповідних захисту середовища. За звітами промисловості, автоматизація може зменшити втрата матеріалів до 20%. BD Зменшуючи відходи і покращуючи ефективність, автоматична технологія виготовлення сумок відповідає більш усім принципам тривалого розвитку, що допомагає середовищу, а також покращує відчуття корпоративної соціальної відповідальності та бренду на зелених ринках.

## Основні особливості сучасних машин для виготовлення сумок

Високшвидкісні можливості виробництва пластикових сумок

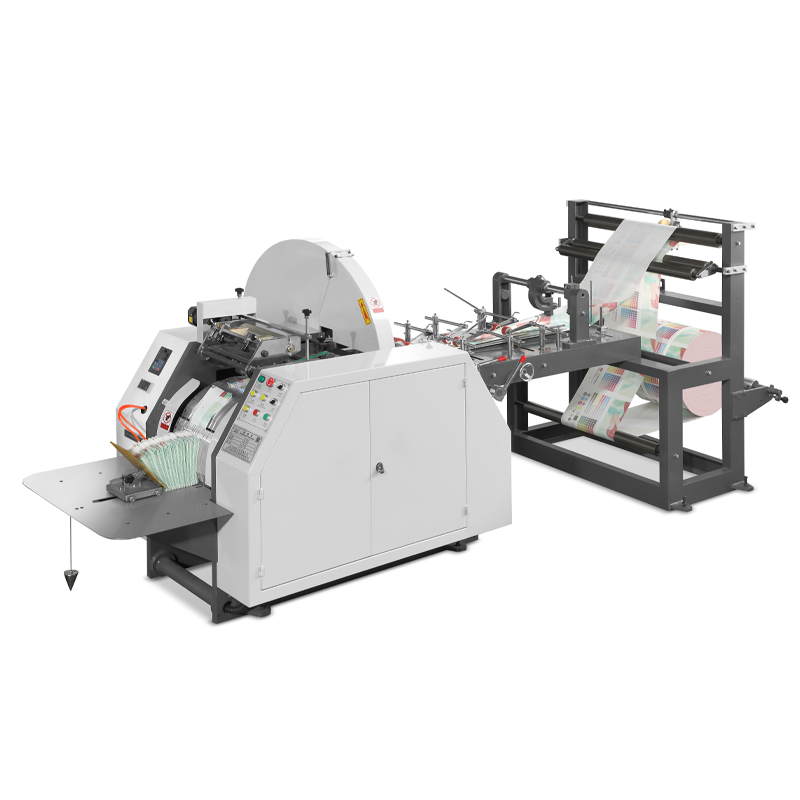

У світі, де швидкість є всього, високоскоростна машина для виготовлення пластикових пакетів може зробити велику різницю. Ці машини здатні виробляти пакети, працюючи швидше за 150 метрів на хвилину. Збільшення швидкості дозволяє підприємствам значно збільшити обсяги виробництва, а отже, ефективність за часом та вартістю. Високоскоростні машини також можуть підвищити ефективність виробництва більше ніж на 50%, надаючи виробникам конкурентних переваг, згідно з бенчмарк вивчень.

Технологія точного виробництва паперових пакетів

Точна конструкція є критично важливою для успішного виробництва найкращих паперових сумок, і саме це ви знайдете в сучасних машинах. Ці машини розроблено з використанням найновіших технологій, метою яких є забезпечення того, щоб всі вироблені сумки мали однаковий розмір та постійні специфікації. Ця система неперервно контролює параметри виробництва за допомогою сучасних датчиків. Свідчення від постачальників показують, що нові складні технології дозволили зменшити дефекти на 40%, і це говорить про те, що вироблена продукція є бездоганною.

Енергоефективна експлуатація для стійкого виробництва

Економія енергії є однією з головних особливостей у машинках для виготовлення сумок, які були розроблені для значної reducії споживання енергії. Використовуючи функції економії енергії, ви можете більше заощаджувати на споживанні енергії. Ці покращення зменшують як операційні витрати, так і вуглецевий слід виробництва. Недавні дослідження показують, що використання енергоефективних машин у виробництві має особливий ефект у стійкому виробництві і може відповідати тенденції, яка призиває до підтримки екологічного виробництва.

## Галузеві тенденції, які формують обладнання для виробництва рулонних сумок

Інтеграція інтелектуальних технологій у машинах для виготовлення поліпропіленових сумок

Впровадження інтелектуальної системи в машині для виготовлення поліпакетів є значною тенденцією для підвищення ефективності та продуктивності в цьому секторі. Застосування Інтернету речей (IoT) дозволяє реалізувати ці машини для онлайн-моніторингу та використовувати їх у аналітиці даних, що дає виробникам можливість неперервно адаптуватися та оптимізувати процес виробництва. Ця сучасна система моніторингу дозволяє запобігти гіршенню якості продукції, а також покращує графік технічного обслуговування, що зменшує вартість простою. Статистика з відомих відомостей показує, що майже 80% виробників планують вкладати у ці інтелектуальні пристрої як спосіб підвищення загального виробничого виводу та ефективності.

Крім того, здатність прогнозувати можливі несправності у машин через аналіз даних, ще до їх виникнення, дозволяє ефективно зменшити час на ремонт та забезпечити більш рівномірний хід виробництва. Впроваджуючи такі інтелектуальні технології, виробники можуть передбачити, коли машинам знадобиться обслуговування, і планувати профілактичне ремонтування, щоб забезпечити мінімальне кількість поломок та простоїв у виробництві. Цей футурологічний підхід не лише продовжує термін служби обладнання, але й відповідає сучасній тенденції до даних-орієнтованого прийняття рішень у галузі виробництва.

Модульні дизайни для сумісності багатьох матеріалів

Модульний концепт машин для виготовлення сумок пропонує максимальну гнучкість, дозволяючи легко переключатися з обробки одного типу матеріалу, наприклад паперу, на інший матеріал, наприклад пластик. Ця гнучкість створює можливості для інновацій та налаштувань, дозволяючи виробникам задовольняти широкий спектр вимог упаковки майже без потреби зупинятися та перепрофілюватися. Коли бізнес намагається залишатися конкурентоспроможним і гнучким щодо змін на ринку, здатність швидко та легко переходіти між виробничими лініями стає все ціннішою.

Модульні машини в кейс-студіях показали, що зменшують перепрофілювання, що призводить до більш високої продуктивності та скоротленого часу налаштування. Ці модульні системи дозволяють виробникам досліджувати нові матеріали та розробляти спеціалізовані рішення для своїх клієнтів, збільшуючи їхню ринкову гнучкість. У сутності концепція модулізації перетворює машини для виготовлення пакетів у загальні типи, які можуть задовольняти всі види виробничих потреб.

Глобальний перехід до стійких розв'язків упаковки

Тренд упаковки для тривалого розвитку змінює обличчя дизайну та виробництва машин для виготовлення пакетів. Коли більше споживачів вимагають екологічно чистої упаковки, виробники не мають іншої можливості, як переглянути, як і за допомогою чого вони працюють. Тренди у тривалому розвитку також стимулюють зростання попиту на біорозкладні матеріали, що спонукає компанії до інвестицій у обладнання, яке може ефективно обробляти ці матеріали на високих швидкостях.

Дослідження, проведені лідерами відраслі, показали, що близько 60%-70% споживачів хочуть, щоб бренди боролися за тривале розвиток. Цей вимоги споживачів ставить виробників під тиск, щоб вони не тільки користувалися екологічно дружніми матеріалами, але й реалізовували процеси виробництва, які найменше впливають на середовище. Акцент на тривалому розвитку гармонійно поєднується з ширшими екологічними урахуваннями та регуляторними вимогами, тому це є важливою стратегією для сталого росту та підтримки споживачів.

## Вибір правильного апарату для виготовлення мішків під ваші потреби

Оцінка вимог до об'єму виробництва

При виборі машини для виробництва мішків, її продуктивність є важливою проблемою. Переконайтеся, що машина здатна задовольняти як поточний, так і майбутній попит (щоб уникнути неефективності та зростання вартості експлуатації). Занадто велика або маленька машина не підходить під ваші вимоги до виробництва, і ви зазряте ресурси або не зможете легко збільшити виробництво. Невідповідність між ємністю - це дуже поширена проблема, яка може суттєво завдає шкоди вашому бізнесу. Статистика галузі показує, що компанії, які обирають машини, враховуючи свої вимоги до об'єму, можуть очікувати покращення ефективності на близько 25%. Відповідно, враховуючи увагу, що приділяється об'єму виробництва, продуктивність та заощадження також можуть бути покращені.

Сумісність матеріалів: папер супроти пластикових мішків

Також важливо знати матеріали, які ви будете обробляти у своєму виробництві, оскільки існують машини, створені для задовolenня потреб певних матеріалів. Незалежно від того, чи використовуєте ви їх для паперу або пластмаси, вибір машини, яка відповідає вашим потребам, є критичним. Іншим недавнім досягненням на ринку є зростаюча популярність машин для двох матеріалів, що дозволяє виробляти як паперові, так і пластикові сумки. Цей тренд можна спостерігати за рахунок 40-процентного зростання попиту на такі машини протягом останніх трьох років. Вибір машини для двох матеріалів для вашого виробництва може покращити гнучкість вашого виробництва та дати можливість реагувати на зміни на ринку, як це необхідно.

Опції налаштування для спеціалізованих рулонних сумок

Функції налаштування на машинках для виготовлення сумок стають все більш бажаними для виробництва спеціалізованих сумок, які замовляють окремі клієнти. Сучасні машини налаштовані виготовляти сумки різних розмірів, форм та призначення для задовolenня різноманітних ринкових запитів. Ця характеристика особливо привабливая, оскільки 70% покупців сьогодні шукають особливих опцій у машинному обладнанні для виготовлення сумок. Маючи машини, які можуть забезпечувати високий рівень налаштування, підприємства можуть задовольняти конкретні потреби клієнтів, що призводить до задоволеності клієнта і переваги над konkurentamy.

Зміст

-

Ручне проти автоматизованого виробництва мішків: ключові аспекти для великопромислового виробництва

- Прихований вартість ручного виробництва рулонних мішків

- Виклики масштабування в традиційних методах

- Екологічний вплив непроцесів без автоматизації

- Високшвидкісні можливості виробництва пластикових сумок

- Технологія точного виробництва паперових пакетів

- Енергоефективна експлуатація для стійкого виробництва

- Інтеграція інтелектуальних технологій у машинах для виготовлення поліпропіленових сумок

- Модульні дизайни для сумісності багатьох матеріалів

- Глобальний перехід до стійких розв'язків упаковки

- Оцінка вимог до об'єму виробництва

- Сумісність матеріалів: папер супроти пластикових мішків

- Опції налаштування для спеціалізованих рулонних сумок