Introduction: Ushering in a New Industrial Revolution in Sustainable Packaging

Driven by global environmental consensus and circular economy policies, the packaging industry is undergoing a profound green transformation. Statistics show that the global sustainable packaging market is projected to exceed $450 billion by 2025, with demand for eco-friendly bags growing at an annual rate of over 18%. In this historic transformation, Eco-Friendly Bag Making Machines are no longer just ordinary production equipment, but core infrastructure for companies to achieve environmental, social, and governance (ESG) goals and build closed-loop supply chains.

From Europe's Single-Use Plastics Directive to plastic restriction regulations in Asian countries, compliance has become a prerequisite for global trade. Meanwhile, over 68% of global consumers are willing to pay a premium for sustainable packaging. This means that investing in professional eco-friendly bag-making technology has shifted from an "optional solution" to a "necessity."

Chapter 1: Why Traditional Equipment Cannot Meet the Needs of Sustainable Production

Traditional bag-making machines were initially designed for traditional plastics such as polyethylene (PE) and polypropylene (PP). However, these devices exhibit significant inadequacies when dealing with novel bio-based materials (such as PLA and PBAT), high-proportion recycled materials, or compostable composite materials:

Different thermal sensitivity: Biomaterials have narrow processing windows, making traditional temperature control systems prone to degradation or inadequate sealing.

Changes in material properties: The unstable rheological properties of recycled materials lead to uneven film thickness and tension fluctuations.

Sealing reliability: Compostable materials require lower temperatures and more precise sealing profiles, which traditional heat-sealing knives struggle to achieve.

High scrap rates: Mismatched process parameters result in scrap rates of 15-25%, significantly exacerbating the cost disadvantage of sustainable materials.

Therefore, a true Eco-Friendly Bag Making Machine must be an integrated system redeveloped based on new materials science, rather than a simple modification.

Chapter 2: Four Core Technological Pillars of Eco-friendly Bag Making Machines

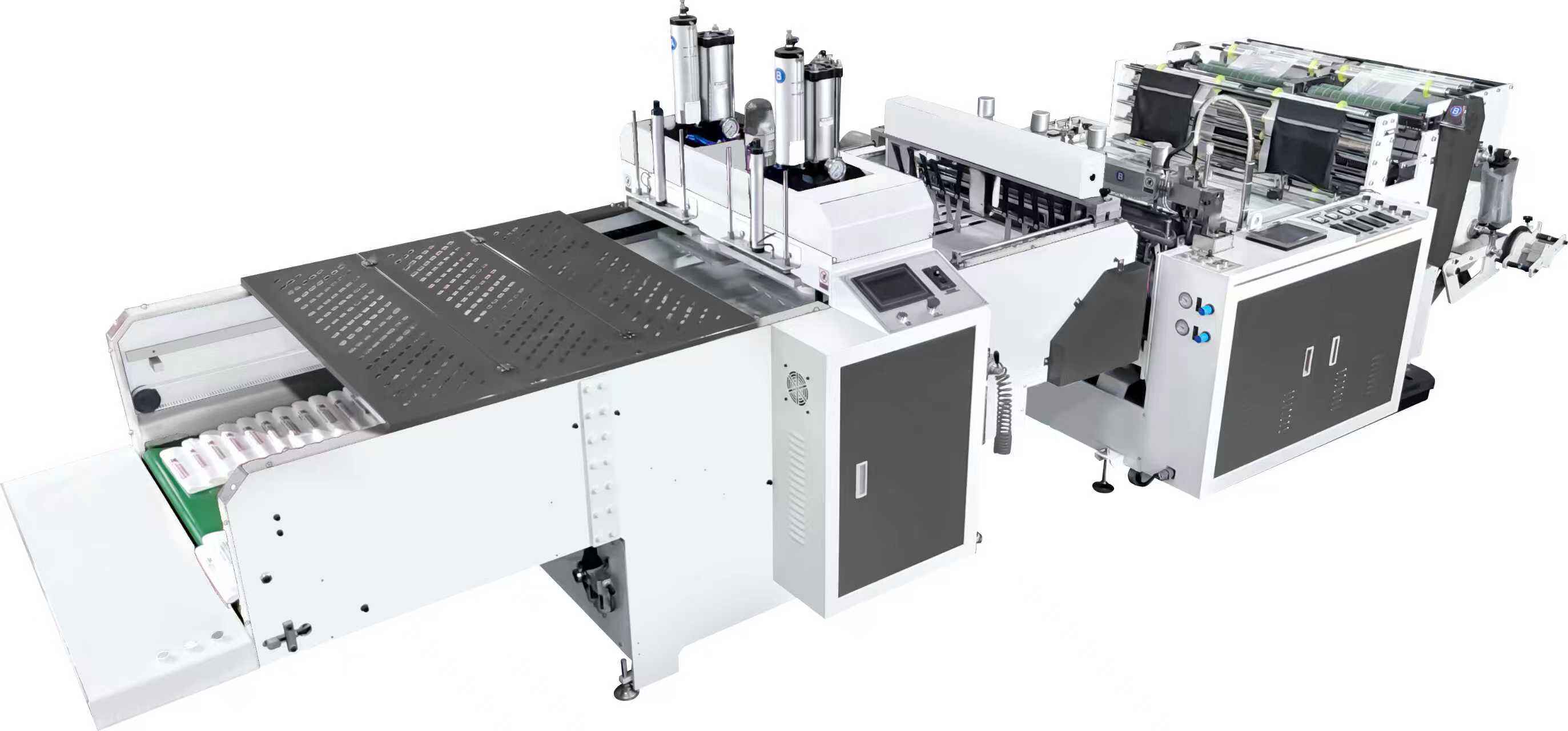

1.Adaptive Material Handling Platform

Our system is equipped with an intelligent material database that can store process formulations for over 50 sustainable materials. Through high-precision metering feeding, two-stage temperature-controlled extrusion (accuracy up to ±1°C), and a specially designed irregularly shaped air ring system for biofilms, stable molding from biodegradable film to HDPE composite substrate is ensured. The unique down-blowing air ring technology, combined with a hexagonal dual-outlet design, improves cooling efficiency by 40% and results in more uniform film crystallinity.

2. Precision Molding and Intelligent Sealing System

Utilizing servo-driven heat sealing and cold cutting technology, sealing temperature, pressure, and time can be synchronized at the millisecond level. This system is particularly adept at producing mainstream eco-friendly packaging such as flat bags, T-shirt bags, and courier bags. The integrated dual-line heat sealing system completes the one-time molding of the bag body and handle in a single stroke, reducing waste material to below 3%. For products requiring high transparency, such as garment packaging bags, low-temperature pulse sealing technology avoids fogging and maintains the material's optical properties.

3 .End-to-End Digital Control Center

A platform based on the Industrial Internet of Things (IIoT) collects over 200 process parameters in real time, dynamically optimizing production cycle time and energy consumption through machine learning algorithms. The system offers predictive maintenance, providing early warnings of anomalies in critical components such as the static eliminator system or air circulation adjustment mechanism. Production data can be used to generate quality traceability reports compliant with major global certifications (such as OK Compost HOME and DIN-Geprüft) with a single click.

4.Modular Rapid Changeover Design

Through standardized interfaces, the production line can quickly switch from producing customized shopping bags to frozen food packaging bags within 2 hours. Optional modules include multi-color printing units, perforation devices for ventilation holes, and compostable marking inkjet printing systems to meet the personalized needs of brand customers.

Chapter 3: Global Application Scenarios and Localized Solutions

Our eco-friendly bag-making technology serves clients in over 40 countries worldwide, offering in-depth customization for different markets:

European High-End Market: To meet EU EPR regulations, we provide courier bag production lines with integrated RFID tag embedding, enabling single-item-level recycling traceability. In Germany, our automated bag-making system seamlessly integrates with the local recycling system, ensuring stable production using ≥80% post-consumer recycled materials (PCR).

Asian Growth Market: For the high-temperature and high-humidity environment of Southeast Asia, we have developed a moisture-proof biodegradable shopping bag production line, increasing material moisture tolerance by 3 times. In Japan, our compact T-shirt bag making machine is designed for convenience stores and small retailers, reducing floor space by 30% and meeting the country's stringent JIS biodegradability certification standards.

Emerging Manufacturing Hubs: In Turkey, our localized service provider, Poşet Üretim Makinesi, supports a smooth transition from traditional PE bags to compostable bags. Equipment interfaces and technical support are available in Turkish, and we train our local engineering team to ensure over 98% equipment uptime.

Chapter 4: ROI Analysis from Cost Center to Value Engine

Choosing professional environmentally friendly bag-making equipment is a strategic investment with clear financial returns:

Direct Economic Benefits

Material Savings: Precise process control enables sustainable material utilization rates of over 96%, saving an average of 15-25% in raw material costs annually.

Energy Efficiency: Integrated heat recovery and high-efficiency drive systems reduce energy consumption per unit output by 35-40%.

Labor Optimization: Increased automation reduces reliance on skilled workers; a production line requires only 1-2 operators.

Indirect Strategic Value

Market Access: Gain access to the global green supply chain, such as being on the sustainable packaging supplier lists of giants like Walmart and Amazon.

Brand Premium: Help clients achieve their carbon neutrality commitments and support them in obtaining sustainable business certifications such as B Corp.

Risk Mitigation: Preemptively meet regulatory upgrade requirements for the next 5-8 years, avoiding the risk of production line obsolescence due to policy changes.

Typical customer case studies show that the investment payback period is generally between 18-28 months, after which green premium profits continue to be generated.

Chapter 5: Choose Us – Your Full-Lifecycle Partner for Sustainable Packaging

We offer more than just equipment; we provide full-lifecycle value services from assessment to continuous optimization:

Initial Consultation and Laboratory Testing: Free testing of your sustainable formulations in our materials lab, providing a complete process feasibility report.

Turnkey Projects and Training: Covering plant planning, equipment installation, process commissioning, and comprehensive staff certification training to ensure rapid production ramp-up.

Continuous Optimization Services: Regular software upgrades and process packages for new materials; remote diagnostic systems providing 24/7 technical support; annual energy efficiency and carbon footprint optimization reports.

Circular Ecosystem Connections: Assisting in connecting you with high-quality global biomaterial suppliers and recycling networks to build your green supply chain loop.

Conclusion:Defining the Future of Packaging Together

The ultimate form of packaging is one that, after fulfilling its mission of protecting and delivering goods, gracefully returns to nature or is recycled. The Eco-Friendly Bag Making Machine for Sustainable Packaging is the industrial cornerstone for realizing this vision.

Today's choices determine tomorrow's heights. Whether it's producing biodegradable custom shopping bags, ocean-derived plastic parcel bags, or carbon-neutral clothing packaging, we will provide world-leading technology and unwavering partner support.

Let us work together to transform our green commitments into measurable, scalable, and sustainable industrial realities, making your trust worthwhile.

Hot News

Hot News