Starting a plastic packaging business can be both exciting and challenging, especially when it comes to selecting the right machinery. The right equipment not only determines your production efficiency but also affects your bottom line. As an industry professional, I've seen businesses struggle with the wrong machinery choices and others thrive by adopting a strategic approach. Let's explore the essential machinery you'll need to establish a successful plastic packaging company, along with some cost-saving tips.

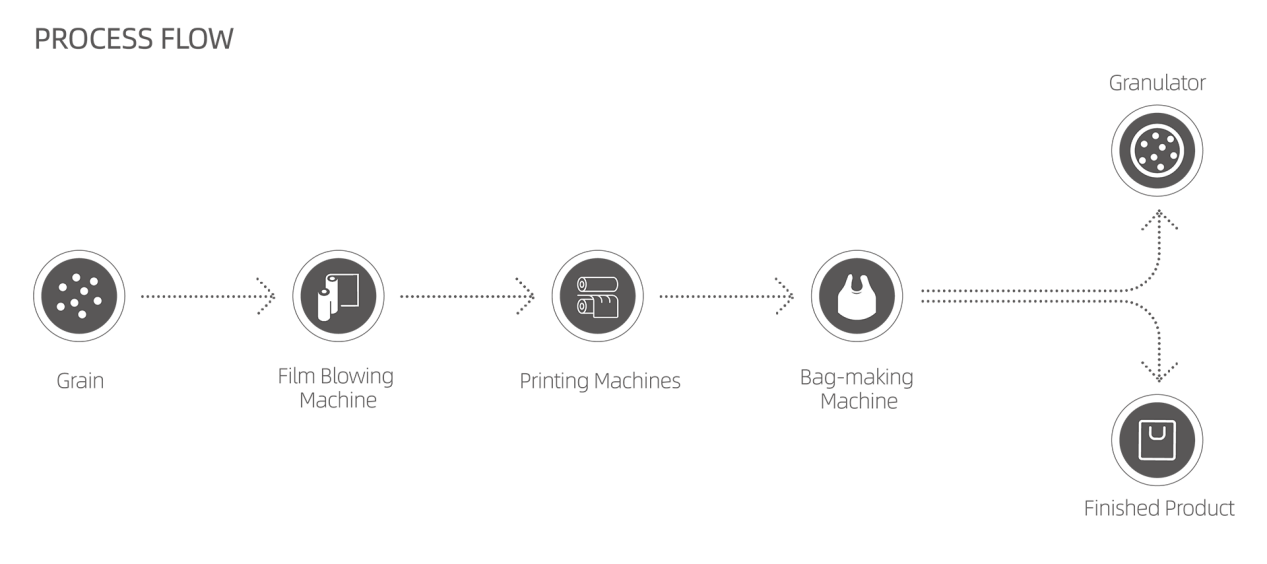

At the heart of any plastic packaging operation are blown film extrusion machines, bag making machines, printing machines, and recycling machines. These four categories form the backbone of your production line. Blown film extrusion machines is responsible for creating the thin plastic films that serve as the raw material for your packaging. When choosing a blown film extrusion machine, consider factors like extrusion capacity, temperature control precision, and film thickness consistency. A high-quality blown film extrusion machine should be able to handle various resins, including PE, PP, and PET, and produce films with uniform thickness to ensure consistent downstream processing.

Bag making machines comes next in the production chain, converting the blown film extrusion machine produced films into finished bags. There are several types of bag making machines, including flat bag machines, continuous bag machines, and bottom-sealing bag machines, each suited for different packaging needs. For instance, if you're planning to produce shopping bags, a vertical bag making machine might be more efficient, while flat bag machines is better suited for producing small bags like those used for snacks. When evaluating bag making machines, pay attention to features like automation level, sealing precision, and bag size adjustability. A good bag making machine should allow quick die changes and support multiple bag sizes without requiring major adjustments.

Printing machinery is crucial for adding your brand's identity to the packaging. Depending on your requirements, you might choose between gravure printing machines and flexographic printing machines. Gravure printing machines offers higher print quality and color saturation, making it ideal for complex designs and large production runs. However, it requires more expensive plates and is less flexible for small batches. Flexographic printing machines, on the other hand, is more cost-effective for smaller orders and simpler designs. If you're targeting a mix of high-end and everyday packaging, consider investing in a multi-functional printing machine that can handle both offset printing and gravure printing, or look into digital printing solutions for greater flexibility.

Finally, recycling machines is an increasingly important part of any responsible packaging business. With growing environmental concerns and stricter regulations, having a high-efficiency pelletizing machine can help you recycle waste material into high-quality pellets, reducing material waste and lowering costs. Recycling machines typically include crushing, washing, melting and pelletizing, and cooling and shaping systems. Look for a recycling machine equipped with automation features, which can continuously process waste material while minimizing manual intervention.

Now, you might be asking: How do I balance quality and cost? Here's a pro tip: Don't skimp on blown film extrusion machines and recycling machines, as these directly impact product quality and long-term sustainability. For bag making machines and printing machinery, consider your immediate needs and plan for scalability. Many manufacturers offer modular systems that can be upgraded as your business grows.

Another thing to consider is the integration of automation control systems. Modern machinery often comes with PLC (Programmable Logic Controller) systems that allow precise parameter adjustments and reduce operator errors. While these systems may cost more upfront, they can lead to significant long-term savings through improved productivity and material utilization.

Finally, don't forget to factor in maintenance costs and operator training. High-end machinery may require specialized skills and regular maintenance, which can add to your operational expenses. Before making a purchase, ask about manufacturer training programs, spare part availability, and service response times.

In summary, establishing a successful plastic packaging business requires a strategic selection of blown film extrusion machines, bag making machines, printing machines, and recycling machines. While initial investments can be substantial, focusing on quality machinery with automation features and scalability will position your business for long-term growth and profitability. Remember, the right machinery is your secret weapon in this competitive industry.