Technological Evolution of Plastic Bag Making Machines

From Manual Operations to AI-Driven Smart Packaging Machines

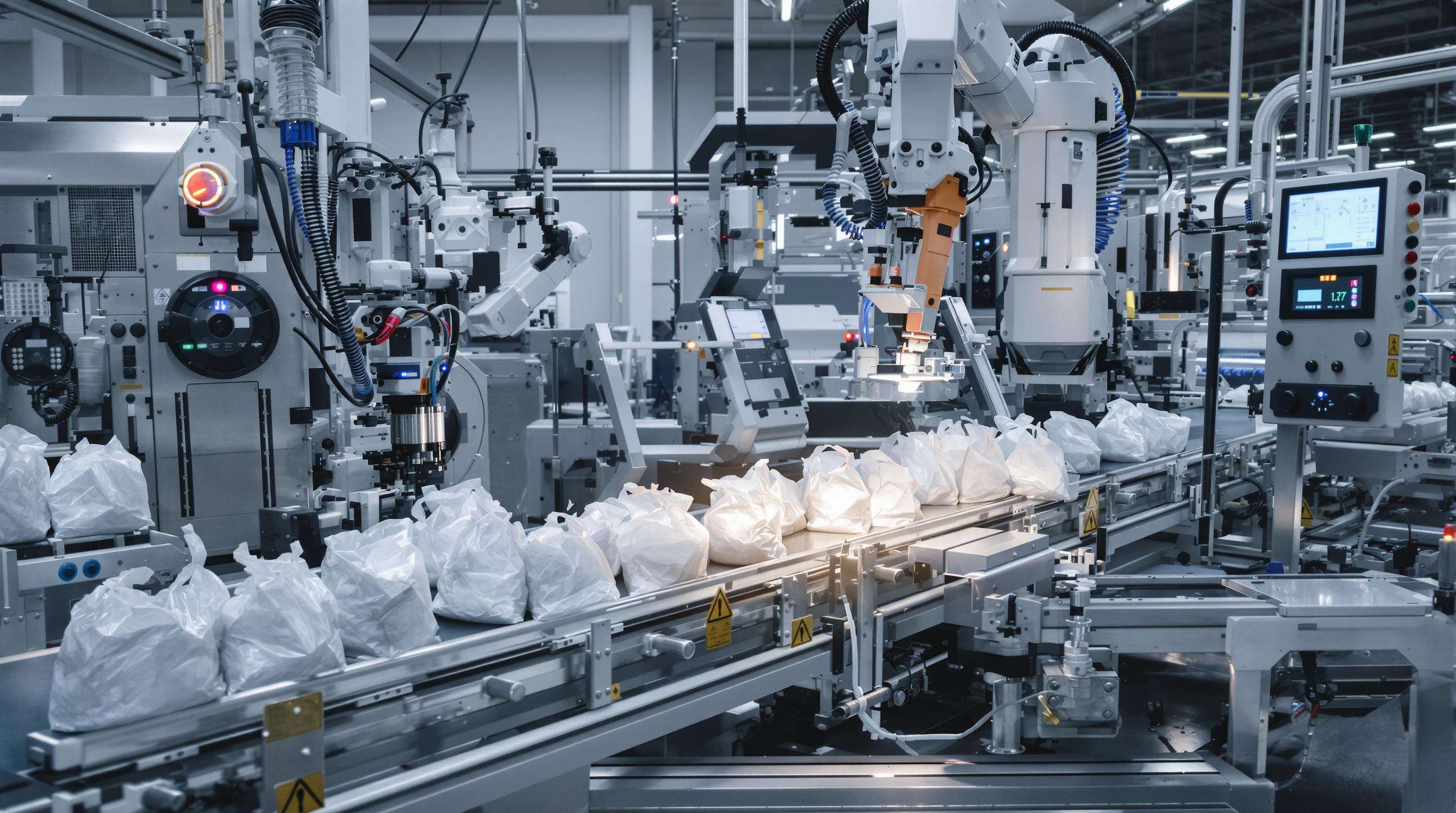

The area of packing system has moved from labour intensive manual operation to automated AI based operation. Early machines had to be constantly monitored by humans, who were often bottlenecks in the production process. Artificial intelligence now is the key driver of the smart packaging machines on the ramp, which carries out real-time self-fiuctuating and self-adjusting of its parameters, intelligent defect inspection, and automatic output optimization without human intervention. This type of industry analysis on the progression of automation categorizes this kind of system as a way that sensors decrease redundancy by real time adjustment and predictive errors so that manufacturing floors actually become data driven machines.

Key Components Enabling IoT Integration in Bag Manufacturing

Key equipment hardware and software enable IoT connectivity in today's bag makers. Industrial-level sensors monitor parameters including film thickness and sealing temperature to within 0.1mm, and use edge computing for localised data processing to enable fast response. Cloud-analytics platforms pull in data across production lines to spot optimisation opportunities using machine-learning pattern recognition. These integrated systems also support encrypted dashboards for real-time off-site monitoring and allow technicians to determine any issues before they lead to failures with over-the-air firmware update push.

Case Study: 35% Efficiency Gains Through Digitalized Workflows

High-performance manufacturing facility adopted IoT driven processes resulting in tangible operational progress in just 6 months. The plant achieved a 47% reduction in setup changeovers thanks to automated calibration presets enabled by retrofitting sensors and cloud analytics to their legacy equipment. Real-time material tracking reduced polyethylene waste by 19% by predicting tension changes during production ramps. Central control's automation created a streamlined workflow for integrated machines, reducing process downtime, and increasing total production throughput by 35% under the 2023 operational metrics.

Automation and AI in Modern Plastic Bag Making Equipment

Real-Time Quality Control Through Machine Vision Systems

Nowadays, sub-millisecond detection of defects is possible in machine vision systems with the help of high-resolution cameras and convolutional neural networks (CNN). These ultra-fast systems analyze 2,400 bags/min over 23 quality parameters - from seal integrity to print alignment - to provide an accuracy rate of 99.9% in packaging innovation trials. Existing technology is a method of removing the limitations of a person's ability in visual observation, specially under low magnification sensor imaging, such as detecting the micron level material defects that result in package failures. Results of implementation show 80% decrease of customer returns due to quality problems and 15% reduction in raw material waste on-the-fly production corrections.

Predictive Maintenance Algorithms Reducing Downtime by 40%

Condition-monitoring sensors inside the machines -extruders, winders, sealing units- produce 18TB of data about operations every month. AI is applied to analyze this information and predict bearing failures 72 hours in advance with 94% confidence. According to the industry analysts, suppliers employing predictive maintenance solutions experience 40% less unplanned downtime and see a 22% extended average life of their equipment. Cross-referencing real time thermal imaging with maintenance logs, the algorithms tweak lubrication cycles and update motor calibration schedules in real time; avoiding cascading mechanical failures.

Industry Paradox: Balancing Automation Costs vs Long-Term ROI

While smart machines provide 18-24 month ROI from increased efficiencies, 63% of converters cite capital expenditure challenges of $2.4 million for full production line upgrades. This paradox fuels hybrid execution methods in which operators keep manual control of batch setup, yet circumvent routine tasks such as bag counting and palletization. Skilling up the workforce Skilling programs like this help close the technical divide and the AR interfaces allow operators to control AI parameters through the AR-based visual interface, which in turn, makes it a non-programming based coding effort. Early adopters who combine partial automation with workforce training capture 85% of full-automation productivity gains at 40% of the cost to implement full automation.

Sustainability Demands Reshaping Packaging Machinery

Eco-Friendly Materials Requiring Adaptive Machine Configurations

The trend toward biodegradable polymers and plant-based materials is changing the face of packaging machinery as we know it. Today’s extrusion lines need intelligent machine concepts and process lines with some adapted die designs for MFI ranges. For example, polylactic acid (PLA) films require a 15–20% reduction in thermal processing windows verses typical polyethylene and thus require accurate sensors and fast response heating elements. Although retrofitting existing machinery to process sustainable materials offers manufacturers 18-24-month ROI payment terms, the purchasing cost continues to deter many SME producers.

Energy Consumption Data: Conventional vs Smart Packaging Machines

| Metric | Conventional Machines | Smart Machines | Reduction |

|---|---|---|---|

| Energy Use per Ton | 850 kWh | 580 kWh | 32% |

| CO2 Emissions (tons/yr) | 1,200 | 820 | 31.7% |

| Data from 2024 Sustainable Packaging Industry Consortium |

Intelligent power management systems in modern equipment optimize motor loads and heating cycles, achieving 30% energy savings without throughput compromises. Machine learning algorithms further reduce idle time by 42% through predictive job sequencing, particularly beneficial for facilities running multiple material grades.

Closed-Loop Recycling Systems Integrated With Production Lines

Some of the large producers now incorporate inline granulation units with the film lines so that trim waste can be regenerated into pellet form. This circular process reduces virgin polymer usage by 35% in high-output plants and meets tensile strength requirements. Real-time viscosity measurement checks support process stability of recycled blends and rejects low-quality batches prior to lamination. The technology also allows for the production of multi-layer recylable bags that substantially satisfy the criteria of both strength as well as the biodegradation standard declared in ASTM D6400.

Market Trends Driving Smart Packaging Machine Upgrades

24% CAGR Growth in Recyclable Bag Making Equipment Sector

The packaging machinery industry for recycled materials is expected to advance at a CAGR of 24% during 2018-28 due to stricter regulations enjoining sustainability compliance and changing consumer behaviour. This growth is strongest in Asia-Pacific, which is experiencing 28% annual expansion on the basis of eco-conscious packaging equipment installations as processors upgrade existing lines with modular biopolymer processing equipment. This increase coincides with the worldwide implementation of USD 1340 billion worth of single-use plastics bans following 2020 driving USD 17.8 billion in machinery upgrades.

Smart Packaging Innovations Fueling Machinery Replacements

IoT-enabled pouch fillers and AI-powered sealing systems now comprise 62% of all new packaging machine investment (early 2020 34%). These intelligent systems make it possible to optimize materials in real time, cutting energy use by 19% and film scrap/waste by 27% compared with conventional models. An industry analysis in 2024 observed that manufacturers were replacing entire production lines rather than individual components on a 5-7 year schedule, developing machine embedded machine learning for adaptive material handling.

Regional Adoption Patterns in Automated Packaging Solutions

North America demonstrates 41% more planned investment in closed-loop recycling integrations, while emerging markets focus on hybrid manual-automated solutions for workforce flexibility. In terms of the automated pouch machine installations in Southeast Asia, the number of installations increased by 18%, with Europe focusing on converting their installed base to become capable of processing compostable material.

Challenges in Implementing Smart Packaging Machine Ecosystems

Data Security Concerns in Connected Packaging Production Lines

The inclusion of IoT leaves packaging lines vulnerable to cyberattacks that aim to steal confidential material formulas and real-time production performance data. An analysis of the North American recyclable bag making machine market revealed 68% of manufacturers now use multilayer encryption techniques to secure machine-to-machine communications. Legacy systems and new IoT modules have vulnerabilities which can result in air-gapped backups being needed on key systems such as variable-thickness film control algorithms.

Workforce Skill Gaps in Operating Advanced Bag Making Machines

The move to neural network-based defect detection has meant that 41% of the traditional mechanical maintenance skills are no longer viable.” Now, the operator requires a hybrid knowledge base of polymer science and Python scripting to maximize such parameters as blown-film cooling rates. This bifurcated need delays the return on investment of automated lines by around 8-12 weeks per technician training cycle.

Material Compatibility Issues With Next-Gen Packaging Technologies

High-starch bioplastics challenge conventional extrusion screws designed for synthetic resins, causing inconsistent seal strengths. Trials show retrofitting adaptive torque control modules reduces material-related downtime by 37%, but requires reconfiguring downstream processes like printing and gusseting stations. These technical constraints slow adoption of compostable materials despite regulatory pressures.

FAQ

What is the role of AI in modern plastic bag making machines?

Artificial intelligence is crucial in modern machines for real-time self-adjustment of parameters, intelligent defect inspection, and automatic output optimization, minimizing human intervention and making production data-driven.

How do IoT integrations benefit bag manufacturing?

IoT integrations in bag manufacturing provide real-time monitoring and analytics that enhance production efficiency, spot optimization opportunities, and prevent failures through predictive maintenance and updates.

What impact does sustainability have on packaging machinery?

Sustainability demands have led to the development of machinery that can process eco-friendly materials, optimize energy use, and incorporate recycling systems, aligning with global regulations and consumer preferences.

How significant are the cost challenges in automating packaging production lines?

Automation can provide economic benefits through efficiency gains, but initial capital expenditures can be substantial, requiring careful balance between short-term costs and long-term ROI.