How Compact Paper Bag Making Machines Work: Core Mechanisms and Functionality

Definition and working principle of a paper bag making machine

Paper bag making machines take raw paper materials and turn them into finished products automatically through several controlled steps. Most units work with either continuous rolls or individual sheets fed along a track system. Servo motors handle the cutting while PLCs control everything else from folding to applying glue and sealing the final product. When compared to hand made alternatives, these automated systems produce much better results with seams that line up properly, dimensions that stay within tight specifications, and significantly less wasted material. This helps companies meet their sustainability targets too. The latest industry data shows something interesting: around three quarters of small businesses that invest in such equipment report getting at least 95% accurate dimensions on their output. That kind of precision matters a lot when it comes to meeting retailer requirements.

Sheet-fed systems and their role in simplifying small-scale production

Sheet fed systems give businesses the kind of flexibility they really need when running smaller batches. The operators just grab those pre cut sheets themselves instead of dealing with big bulky roll handling machines. This cuts down on upfront costs quite a bit too maybe around 30 percent according to Packaging Efficiency Journal from last year. What makes these systems so handy is how fast they can switch between different designs. We've seen them work wonders for things like those fancy bakery bags that change seasonally, special edition retail pouches for holidays, or even limited run gift packages that brands want to test out before going full scale.

Key processes: Cutting, folding, shaping, gluing, and sealing

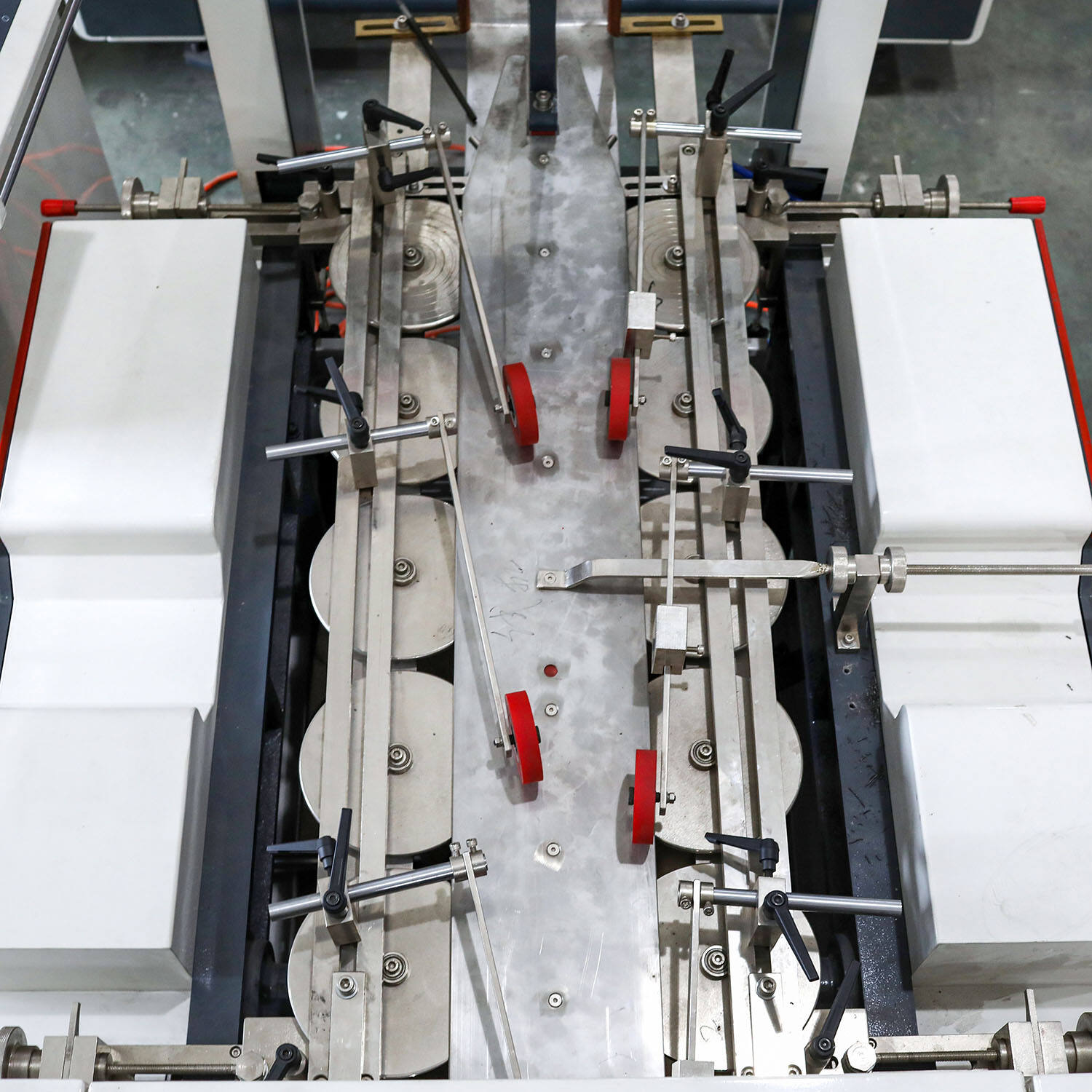

- Cutting: Precision blades trim paper to specified dimensions using digital templates stored in the machine€™s memory.

- Folding: Pneumatic arms fold the paper into walls and bases with sharp, consistent creases.

- Shaping: Vacuum plates or mechanical molds form the three-dimensional structure of the bag.

- Gluing: Food-grade adhesives are applied to seams at controlled temperatures (120-150°C), ensuring strong, instant bonds.

- Sealing: Heated plates or ultrasonic welders close the bottom of the bag, creating durable, leak-proof seals suitable for food-safe packaging.

Types of Compact Paper Bag Machines for Small Businesses

Semi-Automatic vs. Inline Machines: Features and Suitability for Startups

Startups often go for semi automatic machines because they cost much less money upfront, usually between fifteen thousand to thirty five thousand dollars, plus they don't need workers to spend weeks learning how to operate them. What these machines do is pretty straightforward actually they still need someone to feed the paper manually, but everything after that gets handled automatically including folding, gluing, and sealing operations. Most shops can expect production rates somewhere around four hundred to eight hundred bags each hour with this setup. On the other hand, inline systems offer complete automation from start to finish right from when sheets enter until finished products get stacked ready for shipping, which means output jumps well above one thousand two hundred bags per hour mark. According to recent data from the Small Scale Packaging Industry Report released in early 2024, nearly seven out of ten micro businesses start their journey with semi auto equipment so they stay flexible when making adjustments to designs or materials. Meanwhile, those looking at bigger wholesale deals tend to invest in inline systems since they handle large volumes so efficiently.

Material Compatibility: Handling Kraft, Laminated, and Specialty Papers

Small compact machines can work with various kinds of materials, though kraft paper remains the go to choice for many businesses because it's tough enough for most jobs yet still environmentally friendly when disposed of properly. When dealing with heat sensitive laminated papers, operators need to watch temperatures closely around the 120 to maybe 180 degree mark to keep adhesives from failing during production runs. Some trickier stuff like metallic coated or really textured papers call for upgraded equipment featuring better sheet gripping mechanisms and blades that won't dull quickly. Manufacturers have made progress lately too, with newer machines capable of switching from one paper type to another within about fifteen minutes flat. This flexibility makes life easier for local bakeries wanting holiday boxes or gift shops needing special packaging themes throughout the year without having their operations grind to a halt waiting for changes.

Handle Attachment Options for Shopping, Gift, and Retail Bags

Three primary handle types dominate small-scale production:

- Twisted paper handles: Integrated during bag formation, best for lightweight retail use

- Ribbon handles: Added via optional modules, popular among luxury boutiques

- Reinforced flat handles: Applied with heat-sealed tape, commonly used in grocery totes

According to a 2023 Sustainable Packaging Coalition study, 42% of consumers perceive bags with reinforced handles as higher quality, justifying the 10-15% increase in material cost for businesses targeting premium markets. Entry-level machines typically support one handle type, while modular platforms allow upgrades as branding needs evolve.

Production Capacity and Operational Efficiency in Small-Scale Settings

Measuring output: Bags per hour and daily production estimates

Most compact paper bag machines churn out between 800 to 1200 bags every hour, which means around 6400 to 9600 units get made over the course of an 8 hour workday. The actual number depends on what kind of bags are being produced though. Flat bottom designs need extra folding steps that slow things down quite a bit, cutting production speeds by roughly 15 to 20 percent compared to basic t shirt style bags. When changing materials mid shift, setup times usually eat up somewhere between 10 and 30 minutes each time. That's why many manufacturers try to batch similar orders together whenever possible to cut down on these interruptions and keep their machines running smoothly throughout the day.

Case study: Optimizing output in a local micro-factory

The little family-run bakery in Manchester saw a big boost when they ramped up production from just 500 to nearly 900 bread bags each day after restructuring how they used their equipment. They started focusing on making large quantities of plain bread early in the mornings while saving the afternoon shifts for those fancy printed designs customers love so much. This simple scheduling change cut down on switching between different production runs by almost half. And when paired with regular checkups every three months, their machines stayed running smoothly most of the time - clocking in at 92% uptime compared to what other small bakeries typically manage at around 85%.

Balancing efficiency with energy use and labor costs

Running a standard 2.2 kW machine will set back around four bucks eighty cents on electricity each day when rates hit twelve cents per kilowatt hour. Labor still takes up most of the budget though because someone needs to feed material into the system and check product quality manually, typically needing between one and two employees for these tasks. According to last year's Pellet Production Report from industry analysts, factories that installed semi automated equipment with those special misfeed detection sensors saw their labor time drop by about a third, making the investment worth it after just fourteen months or so. Companies looking at long term savings should consider upgrading to IE3 rated motors or better since these efficient models cut annual power bills by well over two hundred dollars versus regular motor types.

Applications in Retail and Small Business: From Bakeries to Boutiques

Custom Paper Bag Production for Shopping, Food, and Clothing Retailers

Small shops can now make their own custom paper bags thanks to compact manufacturing equipment. Retailers across food stores, fashion outlets, and grocery shops are finding these machines invaluable for creating packaging right when they need it, cutting down on dependency on outside suppliers who often charge extra fees. Take local bakeries for instance many have invested in machines that handle grease resistant materials specifically needed for wrapping their fresh baked goods. The market for these specialty bakery packages is growing fast around 17% according to recent industry reports. Fashion retailers also get creative with in house printing capabilities producing simple yet stylish bags featuring their logos which customers actually want to carry home after shopping. These customized solutions not only save money but help build stronger connections between brands and consumers through distinctive packaging experiences.

Tailoring Designs for Bakery, Gift, and Pharmaceutical Packaging Needs

Different industries prioritize distinct functional features:

- Bakeries: Need reinforced seams and moisture-resistant liners

- Gift shops: Favor handles and metallic finishes for visual appeal

-

Pharmacies: Require tear-resistant paper with secure closures

Modern compact machines accommodate these needs through adjustable folding mechanisms and modular glue applicators, supporting paper weights from 60 GSM to 200 GSM.

Real-World Example: A Boutique Adopting In-House Bag Manufacturing

One local clothing store managed to slash their packaging expenses by around 30 percent once they brought in a semi automatic paper bag machine. Now they can crank out between 500 to maybe 700 custom printed bags each day whenever needed, which means no more dealing with those pesky minimum order requirements from outside suppliers. Getting the staff up to speed took less than eight hours total, something that makes sense for smaller operations wanting to bring manufacturing in house without needing a team of experts sitting around all day.

Workflow Integration Tip: Pairing the machine with a digital printer allows real-time design updates, ideal for seasonal promotions or limited-edition packaging.

Scalability and Long-Term ROI of Compact Paper Bag Making Machines

Compact paper bag making machines offer scalable pathways for businesses growing from pilot projects to full-scale operations. When operated at 60-70% capacity, these systems typically achieve payback within 18-24 months, with operators reporting productivity gains of 300-400% after modular enhancements (Ponemon 2023).

Evaluating Growth Potential: When and How to Scale Up Production

Most small manufacturers reach optimal scale at 10,000-15,000 bags per day the practical limit for compact systems. Capacity can be expanded by 30-50% through upgrades like adjustable feeders and dual-purpose dies, often without requiring additional floor space.

Modular Upgrades and Integration With Future Automation Systems

Modern machines support plug-and-play expansions such as auto-glue dispensers and robotic palletizers. This modularity reduces upgrade expenses by 40-60% compared to replacing entire systems. IoT-enabled models also support predictive maintenance, reducing annual downtime by 25%.

Cost Analysis: High Initial Investment vs. Long-Term Savings and Returns

A typical $200,000 investment in semi-automated machinery yields significant operational savings:

| Cost Factor | Traditional Setup | Compact Machine |

|---|---|---|

| Labor Costs | $74,000/year | $29,600/year |

| Material Waste | 15% | 4% |

| Energy Consumption | $12,000/year | $8,400/year |

As highlighted in a 2024 Packaging Automation Study, this setup delivers a 75% ROI within 16 months, driven by 60% lower labor costs and added revenue from premium, customized retail packaging.

Frequently Asked Questions

What is a paper bag making machine?

A paper bag making machine is a device that automatically converts raw paper materials into finished paper bags via controlled steps such as cutting, folding, gluing, and sealing.

What are the advantages of using compact paper bag making machines?

Compact paper bag making machines offer precision, reduced material waste, and flexibility in production, allowing smaller businesses to produce high-quality bags with lower upfront costs and adaptability to different designs.

What kinds of paper can these machines handle?

These machines can handle a variety of papers including kraft, laminated, and specialty papers, with some requiring temperature and equipment adjustments for optimal performance.

How do semi-automatic and inline machines differ?

Semi-automatic machines require manual paper feeding but automate the rest of the process, making them cheaper and easier to use. Inline machines offer full automation and higher production speeds, ideal for larger scale operations.

How does handle attachment work in these machines?

Compact machines can integrate different handle types like twisted paper, ribbon, and reinforced flat handles during the bag formation process, with options varying by machine type.

Table of Contents

- How Compact Paper Bag Making Machines Work: Core Mechanisms and Functionality

- Types of Compact Paper Bag Machines for Small Businesses

- Production Capacity and Operational Efficiency in Small-Scale Settings

-

Applications in Retail and Small Business: From Bakeries to Boutiques

- Custom Paper Bag Production for Shopping, Food, and Clothing Retailers

- Tailoring Designs for Bakery, Gift, and Pharmaceutical Packaging Needs

- Real-World Example: A Boutique Adopting In-House Bag Manufacturing

- Scalability and Long-Term ROI of Compact Paper Bag Making Machines

- Evaluating Growth Potential: When and How to Scale Up Production

- Modular Upgrades and Integration With Future Automation Systems

- Cost Analysis: High Initial Investment vs. Long-Term Savings and Returns

- Frequently Asked Questions